Method for preparing bisphenol F by using 1-alkyl-3-methylimidazole acidic ionic liquid

A technology of acidic ionic liquids and methylimidazoles, applied in chemical instruments and methods, preparation of organic compounds, production of bulk chemicals, etc., can solve problems such as rapid decline in catalyst activity, impact on product scale application, and short catalyst life. To achieve the effect of avoiding difficult recycling and low utilization rate, maintaining good catalytic activity, and being easy to recycle and reuse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

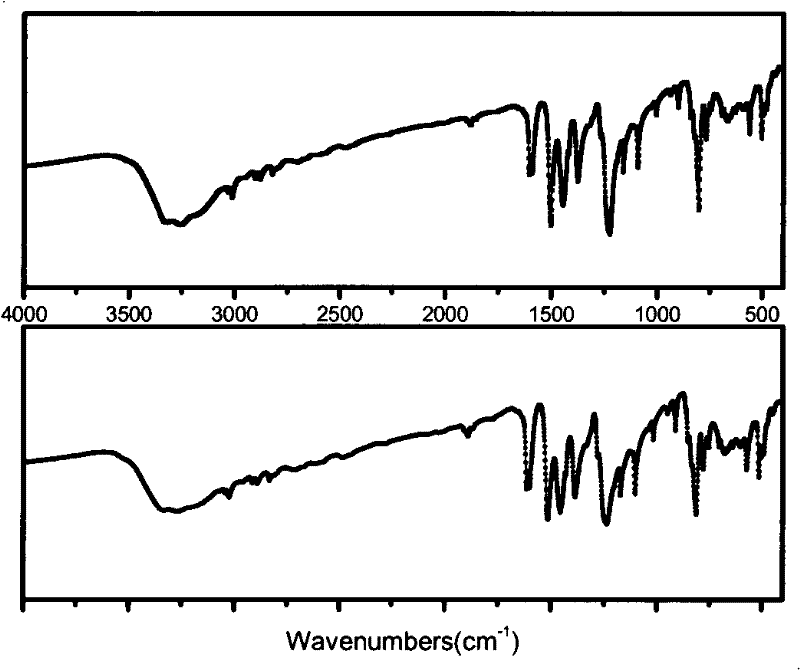

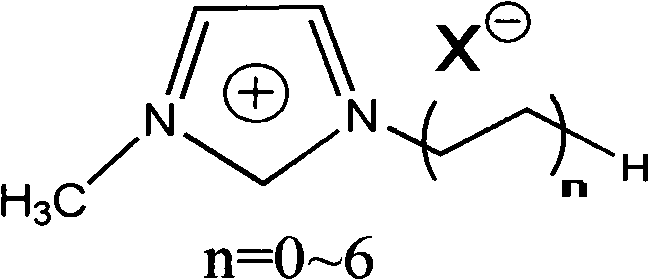

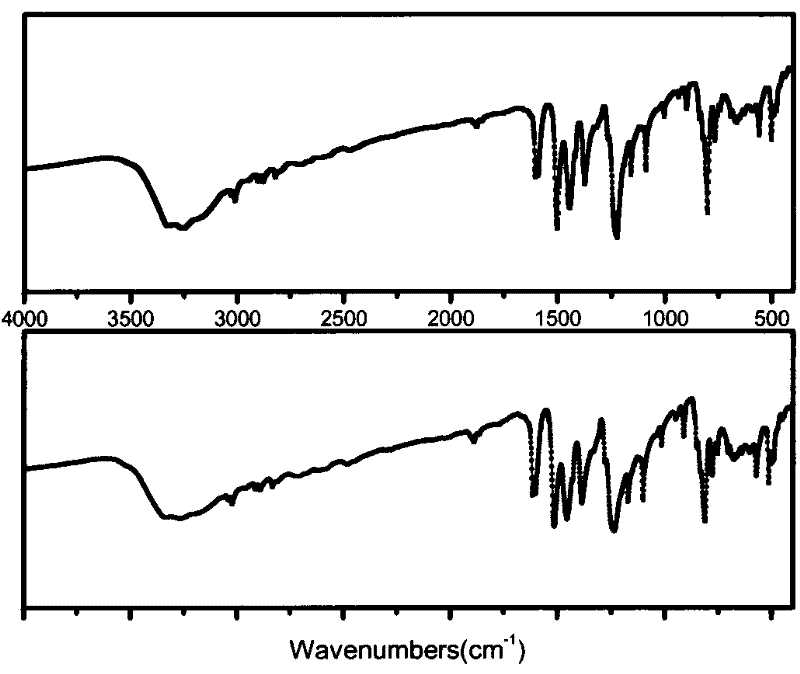

Image

Examples

Embodiment 1

[0022] Take 0.1mol 1-alkyl-3-methylimidazole acidic ionic liquid [Hmin][HSO 4 ] and 0.6mol phenol into the three-necked flask, the temperature was raised to 90°C, and 0.1mol formaldehyde was added dropwise. And samples were taken and analyzed at 0.5h, 1h, 2h, 3h, 4h, 5h, and 6h respectively. After the reaction was finished, it was cooled, washed with water and separated into layers. The aqueous phase was dehydrated by rotary evaporation under reduced pressure, and the remaining ionic liquid was recycled; the organic phase was distilled under reduced pressure to recover phenol to obtain a crude product, which was recrystallized from xylene to obtain bisphenol F product with a yield of 70.68%.

Embodiment 2

[0024] Take 0.1mol 1-alkyl-3-methylimidazole acidic ionic liquid [Emin][HSO 4 ] and 0.7 mol of phenol were added to the three-necked flask, the temperature was raised to 80°C, and 0.1 mol of formaldehyde was added dropwise. And samples were taken and analyzed at 0.5h, 1h, 2h, 3h, 4h, 5h, and 6h respectively. After the reaction was finished, it was cooled, washed with water and separated into layers. The aqueous phase was dehydrated by rotary evaporation under reduced pressure, and the remaining ionic liquid was recycled; the organic phase was distilled under reduced pressure to recover phenol to obtain a crude product, which was recrystallized from xylene to obtain bisphenol F product with a yield of 65.53%.

Embodiment 3

[0026] Take 0.1mol 1-alkyl-3-methylimidazole acidic ionic liquid [Bmin][HSO 4 ] and 0.8mol of phenol were added to the three-necked flask, the temperature was raised to 60°C, and 0.05mol of formaldehyde was added dropwise. And samples were taken and analyzed at 0.5h, 1h, 2h, 3h, 4h, 5h, and 6h respectively. After the reaction was finished, it was cooled, washed with water and separated into layers. The aqueous phase was dehydrated by rotary evaporation under reduced pressure, and the remaining ionic liquid was recycled; the organic phase was distilled under reduced pressure to recover phenol to obtain a crude product, which was recrystallized from xylene to obtain bisphenol F product with a yield of 69.58%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com