Synthesis method of polysulfone resin

The technology of a polysulfone resin and a synthesis method, which is applied in the field of polysulfone resin synthesis, can solve the problems of waste of raw materials, long reaction time and the like, and achieve the effects of wide application, saving raw materials and reducing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

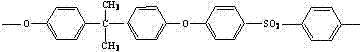

Image

Examples

Embodiment 1

[0015] Add 0.5 mol of 4,4-dichlorodiphenyl sulfone, 0.5 mol of bisphenol A, 525.3 g of N-methylpyrrolidone, 22 g of NaOH and 52.5 g of chlorobenzene into a four-necked flask equipped with a condensing water separator and a thermometer. Stir and heat up under protection to dissolve all the added substances and raise the temperature to 95°C~105°C, the reaction system starts to azeotrope, the water generated by the reaction is continuously evaporated, and the chlorobenzene is refluxed into the reaction flask. During the reaction process, N-methylpyrrolidone was continuously added dropwise to replace the steamed water to maintain the liquid level balance. After all the water in the reaction system was azeotropically taken out, the reflux was continued for 30 minutes to steam out the chlorobenzene. The temperature was raised to 220°C, and after continuing the reaction for 6 hours, cold N-methylpyrrolidone was added to control the system temperature at 165°C-185°C. Flush into the re...

Embodiment 2

[0016] Example 2: After the temperature was raised to 220° C., the reaction was continued for 7 hours. Other operations are the same as in Example 1.

Embodiment 3

[0017] Example 3: After the temperature was raised to 220° C., the reaction was continued for 8 hours. Other operations are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com