Formula and preparation method of epoxy resin based anisotropic conductive adhesive film

An epoxy resin, anisotropic technology, applied in the field of preparation of functional polymer-based composite materials, can solve problems such as high temperature, easily damaged components and substrates, and failure to meet process requirements, etc., to achieve high resin viscosity and increase High cohesive force and high cross-linking density of cured product

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] The preparation process of ACAF is as follows:

[0030] First, surface-treat the conductive particles with part of the silane coupling agent to improve their dispersion in the epoxy resin matrix, that is, weigh a certain amount of conductive particles according to the above formula, add an appropriate amount of active diluent, and ultrasonically stir Then add part of silane coupling agent, and continue to stir the slurry for 3 hours in ultrasonic water bath with timing electric stirrer; then weigh a certain amount of mixed epoxy resin according to the above formula, add the remaining active diluent and coupling agent, After stirring evenly, add curing agent, curing accelerator and gas phase SiO 2 , fully stirred, and mixed evenly; then add the surface-treated conductive particle slurry into the resin mixture, stir well, and mix evenly; finally add stabilizers and tougheners, stir evenly, and then coat. The coating temperature is 80°C-90°C, and it takes 5-7 minutes to coa...

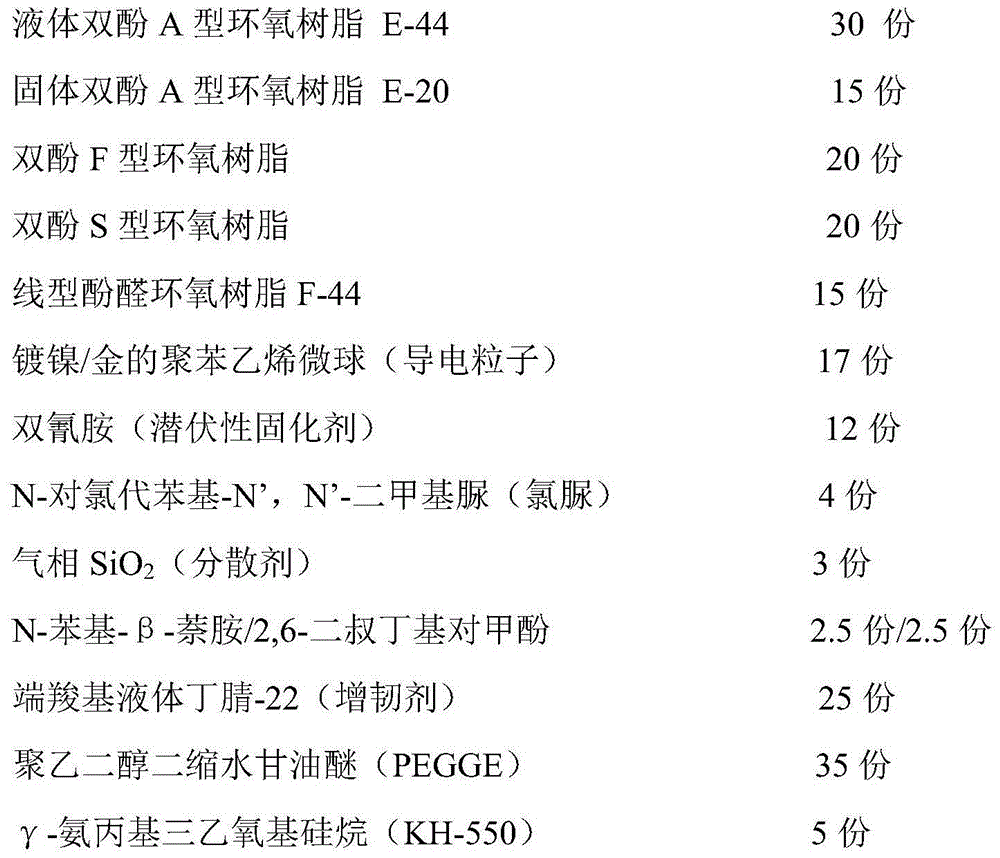

Embodiment 1

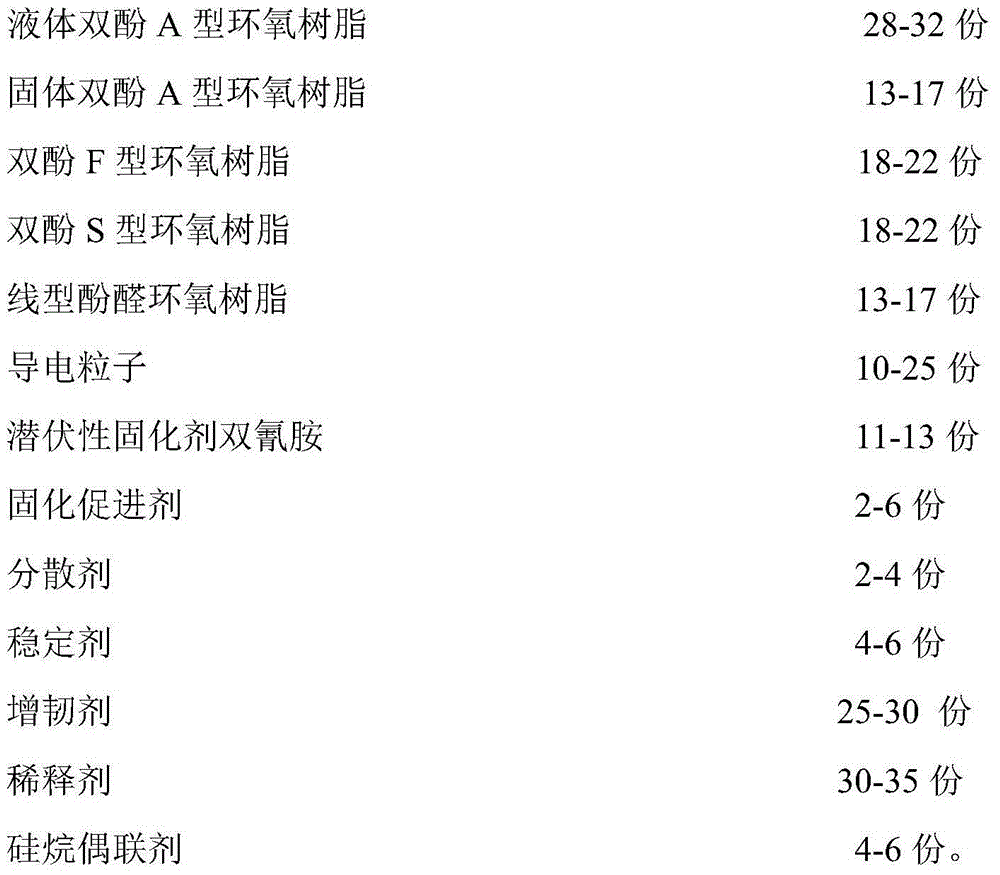

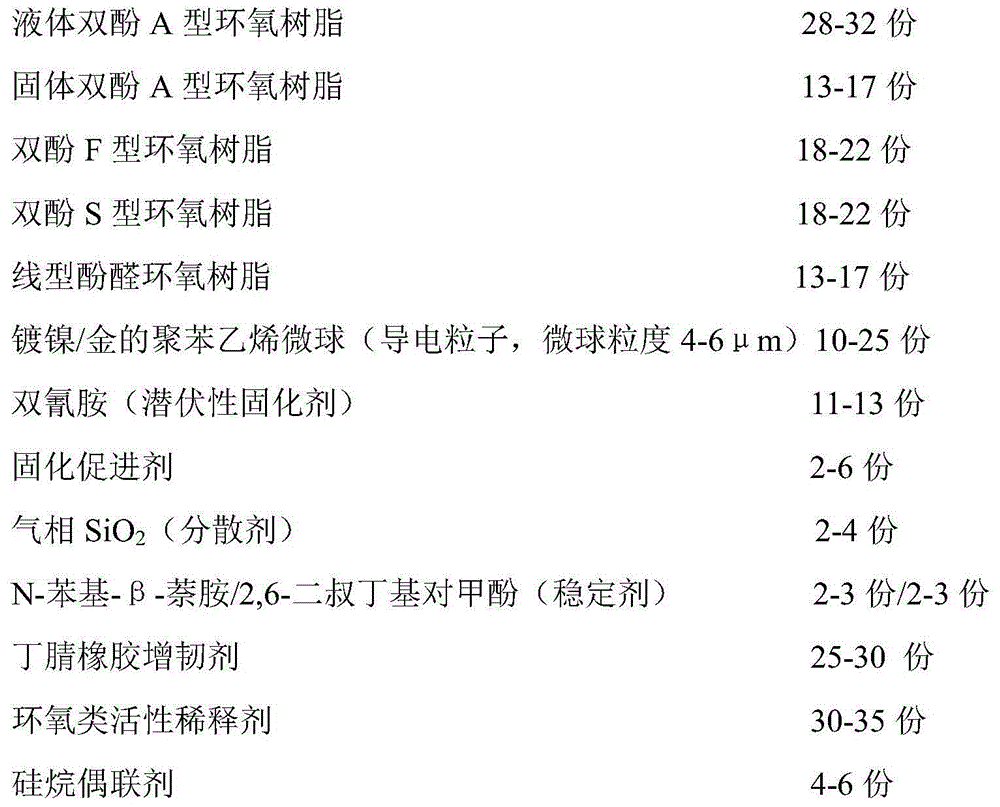

[0033] A kind of epoxy resin-based anisotropic conductive adhesive film (ACAF) formula is as follows:

[0034]

[0035] First, weigh 17g of conductive particles according to the above formula, add 20g of PEGGE, add 3g of KH-550 under ultrasonic stirring, and continue to stir the slurry in an ultrasonic water bath with a timing electric stirrer for 3 hours; then weigh 100g according to the above formula and mix Epoxy resin, add the remaining 15g of PEGGE and 2g of KH-550, stir well and then add 12g of dicyandiamide, 4g of chlorourea and 3g of gas-phase SiO 2 , fully stirred, and mixed evenly; then the surface-treated conductive particle slurry was added to the resin mixture, fully stirred, and mixed evenly; finally, 2.5g of N-phenyl-β-naphthylamine / 2.5g of 2,6 -Di-tert-butyl-p-cresol and 25g of carboxyl-terminated liquid butyronitrile-22, stirred evenly and then coated.

[0036] Coat it on the surface-treated polyester film on the coating machine. The temperature of the dry...

Embodiment 2

[0044] The difference between this example and Example 1 is only: the curing accelerator chlorourea in Example 1 is replaced by 2,4,6-three (dimethylaminomethyl) phenol (DMP-30) 2-ethylhexanoic acid) salt, consumption is 4g, and others all remain unchanged, and test result is as follows:

[0045] Curing temperature: 130°C

[0046] Curing time: 30s

[0047] Storage period (25℃): 45days

[0048] Peel strength: 16N / cm

[0049] On-resistance: 4Ω

[0050] Insulation resistance: 5.8×10 11 Ω

[0051] From the results of Example 1 and Example 2, it can be seen that both curing accelerators can effectively reduce the curing temperature of epoxy resin and shorten the curing time, especially the catalytic effect of chlorourea is more significant, but it also makes the resin glue The pot life of the solution is shortened by 3-6 weeks. Although the catalytic effect of DMP-30 tris (2-ethylhexanoic acid) salt is slightly inferior to that of chlorourea, it not only does not affect the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Peel strength | aaaaa | aaaaa |

| Insulation resistance | aaaaa | aaaaa |

| Peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com