Synthesis method of bisphenol F in salt bath system

A synthesis method and system technology, applied in chemical instruments and methods, preparation of organic compounds, organic chemistry, etc., can solve the problems of great harm to human body, environmental pollution, etc., and achieve low environmental pollution, simple preparation method and high yield Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

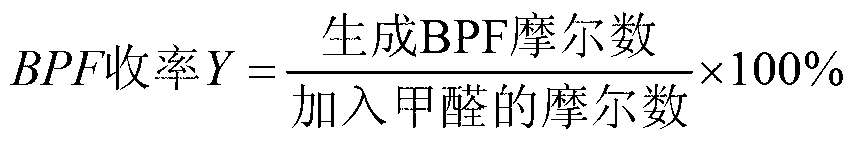

Image

Examples

Embodiment 1

[0023] Take the formaldehyde 8.12g that mass concentration is 37% in the raw material as example, the method for synthesizing bisphenol F under the salt bath system is by following steps:

[0024] (1) Ingredients

[0025] Weigh 8.12g of formaldehyde with a mass concentration of 37%, 127.05g of phenol, 10.85g of hydrochloric acid with a mass concentration of 37%, and 27.63g of potassium oxalate, and mix them in a 250mL three-necked flask. The molar ratio of formaldehyde to phenol, catalyst, and salt is 1 :13.5:1.1:1.5, stir evenly.

[0026] (2) Reaction

[0027] The mixture in step (1) was reacted at 40° C. for 19 hours under stirring in a constant temperature circulator.

[0028] (3) dry

[0029] Put the reaction solution in a separatory funnel, let it stand for 12 hours to separate the water phase and the oil phase, take the oil phase and put it in a vacuum drying oven at -0.6MPa, and dry it at 85°C for 2.5 hours to prepare crude bisphenol F.

[0030] (4) Recrystallizatio...

Embodiment 2

[0053] Take the formaldehyde 8.12g that mass concentration is 37% in the raw material as example, the method for synthesizing bisphenol F under the salt bath system is by following steps:

[0054] (1) Ingredients

[0055] Weigh 8.12g of formaldehyde with a mass concentration of 37%, 94.11g of phenol, 7.89g of hydrochloric acid with a mass concentration of 37%, and 18.42g of potassium oxalate, and mix them in a 250mL three-necked flask. The molar ratio of formaldehyde to phenol, catalyst, and salt is 1.0 :10.0:0.8:1.0, stir evenly.

[0056] Other steps are the same as in Example 1.

Embodiment 3

[0058] Take the formaldehyde 8.12g that mass concentration is 37% in the raw material as example, the method for synthesizing bisphenol F under the salt bath system is by following steps:

[0059] (1) Ingredients

[0060] Weigh 8.12g of formaldehyde with a mass concentration of 37%, 160.00g of phenol, 13.81g of hydrochloric acid with a mass concentration of 37%, and 36.85g of potassium oxalate, and mix them in a 250mL three-necked flask. The molar ratio of formaldehyde to phenol, catalyst, and salt is 1.0 :17.0:1.4:2.0, stir evenly.

[0061] Other steps are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| Sensitivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com