Fold-resistant white plastic film and preparation method thereof

A technology of plastic film and folding resistance, which is applied in the field of folding-resistant white plastic film and its preparation, can solve the problems of environmental pollution, energy consumption, etc., and achieve the effects of simple preparation conditions, low price, high temperature resistance and whitening resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

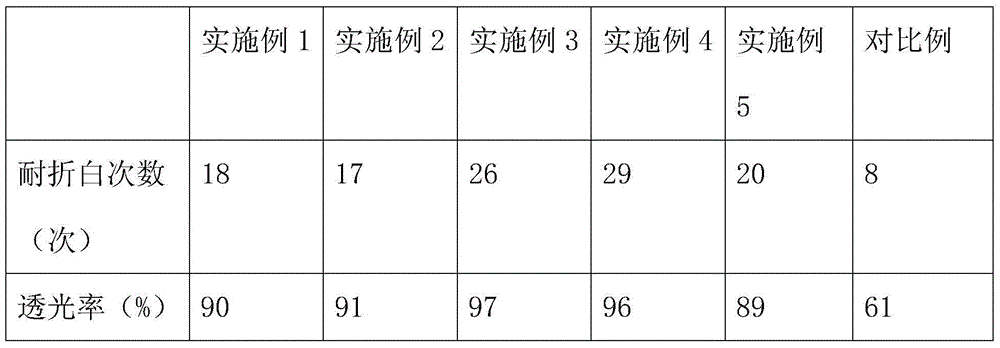

Examples

Embodiment 1

[0027] (1) Mix 18kg of bisphenol S type epoxy resin, 5kg of cellulose acetate butyrate, 1kg of diaminopropyl polydimethylsiloxane, 0.1kg of polymethyl hydrogen siloxane, boron trifluoride-dimethyl Aniline 0.02kg, stir evenly;

[0028] (2) Add to a high-pressure homogenizer with a pressure of 19.8Mpa and a temperature of 55°C and mix for 12 minutes, slowly add 0.02kg of isophoronediamine, and stir evenly;

[0029] (3) Add 55 kg of an aqueous solution of 15 wt % polyethylene glycol, stir at 85° C. for 10 minutes, degas, pour into a flat mold, dry, and demould to obtain a folding-resistant white plastic film.

[0030] Wherein, the average relative molecular mass of the polyethylene glycol is 400.

Embodiment 2

[0032] (1) Mix 18kg of bisphenol S type epoxy resin, 11kg of cellulose acetate butyrate, 1kg of diaminopropyl polydimethylsiloxane, 0.1kg of polymethyl hydrogen siloxane, boron trifluoride-dimethyl Aniline 0.02kg, cobalt oxide 0.5kg, stir evenly;

[0033] (2) Add to a high-pressure homogenizer with a pressure of 19.8Mpa and a temperature of 55°C and mix for 12 minutes, slowly add 0.02kg of isophoronediamine, and stir evenly;

[0034] (3) Add 55 kg of an aqueous solution of 15 wt % polyethylene glycol, stir at 85° C. for 10 minutes, degas, pour into a flat mold, dry, and demould to obtain a folding-resistant white plastic film.

[0035] Wherein, the average relative molecular mass of the polyethylene glycol is 400.

Embodiment 3

[0037] (1) 25kg of bisphenol S type epoxy resin, 11kg of cellulose acetate butyrate, 3kg of diaminopropyl polydimethylsiloxane, 2kg of polymethyl hydrogen siloxane, boron trifluoride-dimethyl Aniline 0.8kg, cobalt oxide 0.5kg, stir evenly;

[0038] (2) Add to a high-pressure homogenizer with a pressure of 20.5Mpa and a temperature of 70°C and mix for 18 minutes, slowly add 0.06kg of isophoronediamine, and stir evenly;

[0039] (3) Add 75 kg of an aqueous solution of 18 wt % polyethylene glycol, stir at 90° C. for 15 minutes, degas, pour into a flat mold, dry, and demould to obtain a fold-resistant white plastic film.

[0040] Wherein, the average relative molecular mass of the polyethylene glycol is 200.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com