Epoxy resin composite material as well as preparation method and application thereof

A technology of epoxy resin and composite materials, which is applied in the field of composite materials, can solve the problems of reducing dielectric constant, increasing material manufacturing costs, and expensive POSS, and achieves the goal of increasing transmittance, reducing power consumption, and increasing signal transmission speed Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

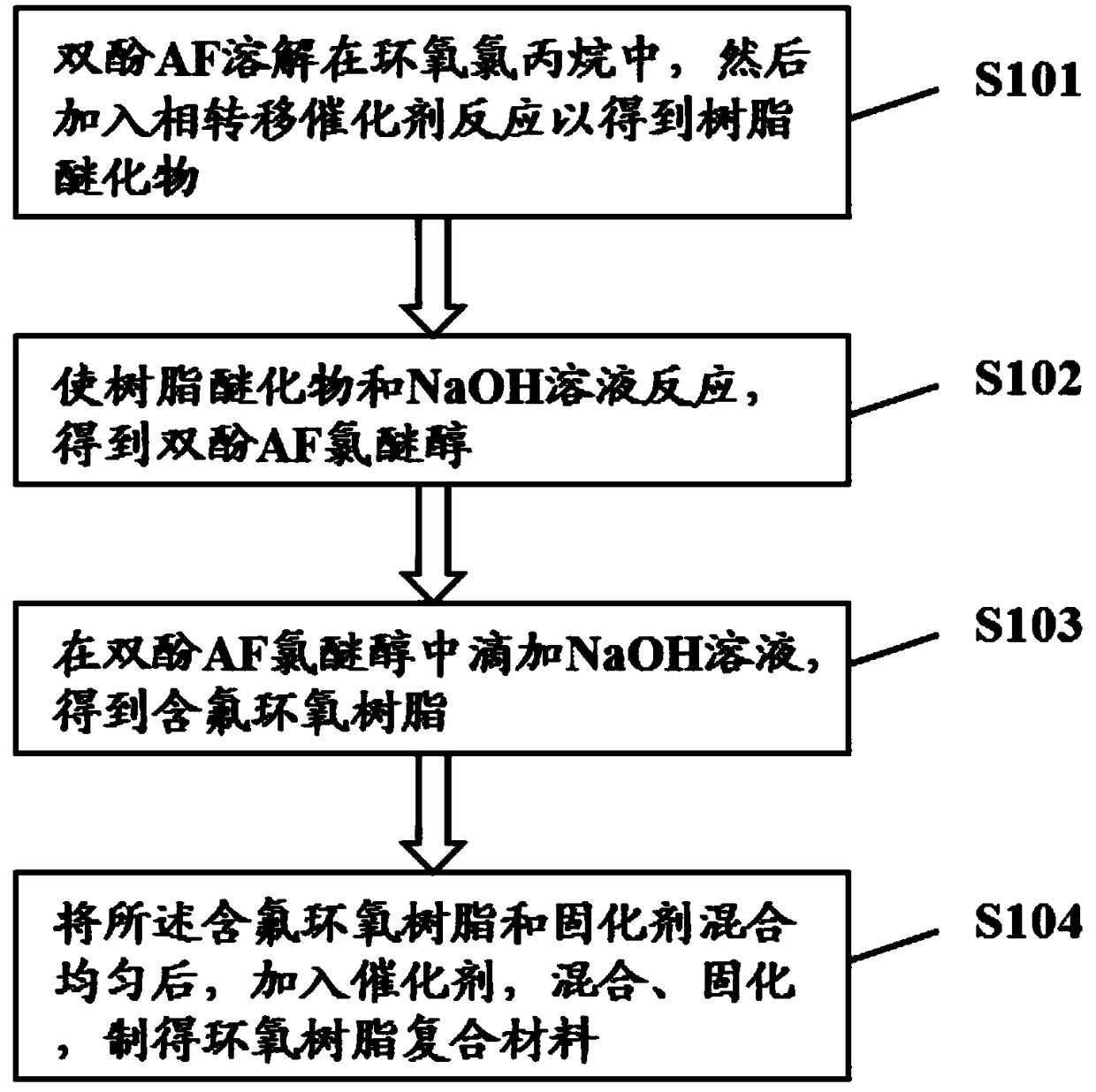

[0022] The preparation method of epoxy resin composite provided by the invention may further comprise the steps:

[0023] Such as figure 1 As shown in step S101, bisphenol AF is completely dissolved in epichlorohydrin, and then a catalyst is added to react to obtain a resin ether compound. In this step, bisphenol AF is completely dissolved in epichlorohydrin at 60-80°C, preferably at 70°C, and then a phase shift catalyst tetrabutylammonium bromide with a mass fraction of 0.05%-0.15% is added Reaction, preferably the phase shift catalyst tetrabutylammonium bromide reaction with a mass fraction of 0.1%, heat preservation for 0.5 to 1.5 hours, preferably heat preservation for 1 hour, to obtain a resin ether compound, wherein the bisphenol AF and the epoxy The molar ratio of chloropropane is 1:2-1:6, preferably 1:4.

[0024] Such as figure 1 As shown in step S102, the resin etherified product is reacted with NaOH solution to obtain bisphenol AF chloroether alcohol. In this ste...

Embodiment 1

[0028](1) Synthesis of fluorine-containing resin: Add bisphenol AF and epichlorohydrin at a molar ratio of 1:4 into a three-neck round bottom flask, vacuumize, feed nitrogen, heat up to 70°C, stir and mix, and wait for bisphenol AF After completely dissolving in epichlorohydrin, add a phase transfer catalyst tetrabutylammonium bromide with a mass fraction of 0.1%, and keep it warm for 1 hour to obtain a resin ether compound, add 30% NaOH solution, and heat it at 70°C for 2 hours to get bisphenol AF chloroether alcohol, wherein, the molar ratio of bisphenol AF and NaOH is 1:0.1, after the completion, the unreacted epichlorohydrin is recovered by vacuum distillation, and then 40% NaOH solution is added dropwise, bisphenol AF and NaOH The molar ratio of the fluorine-containing epoxy resin was 1:1.5, reacted for 2 hours, and the reaction was completed, filtered and washed to obtain a fluorine-containing epoxy resin, wherein the purity of the fluorine-containing epoxy resin was 97%....

Embodiment 2

[0031] (1) Synthesis of fluorine-containing resin: Add bisphenol AF and epichlorohydrin at a molar ratio of 1:4 into a three-neck round bottom flask, vacuumize, feed nitrogen, heat up to 70°C, stir and mix, and wait for bisphenol AF After completely dissolving in epichlorohydrin, add a phase transfer catalyst tetrabutylammonium bromide with a mass fraction of 0.1%, and keep it warm for 1 hour to obtain a resin ether compound, add 30% NaOH solution, and heat it at 70°C for 2 hours to get bisphenol AF chloroether alcohol, wherein the molar ratio of bisphenol AF to NaOH is 1:0.1. Recover unreacted epichlorohydrin, then add dropwise 40NaOH solution, the molar ratio of bisphenol AF and NaOH is 1:2, react for 2h, after the reaction is completed, filter and wash to obtain fluorine-containing epoxy resin, wherein, fluorine-containing epoxy The purity of the resin was 97.5%.

[0032] (2) Preparation of low-dielectric epoxy resin composite material: Mix fluorine-containing epoxy resin ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com