Tear-resistant fluoro-rubber mixed compound and preparation method thereof

A fluororubber raw rubber and fluororubber technology is applied in the field of tear-resistant fluororubber compounding and preparation, which can solve the problems of poor tear performance of fluororubber and achieve the effect of good tear resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

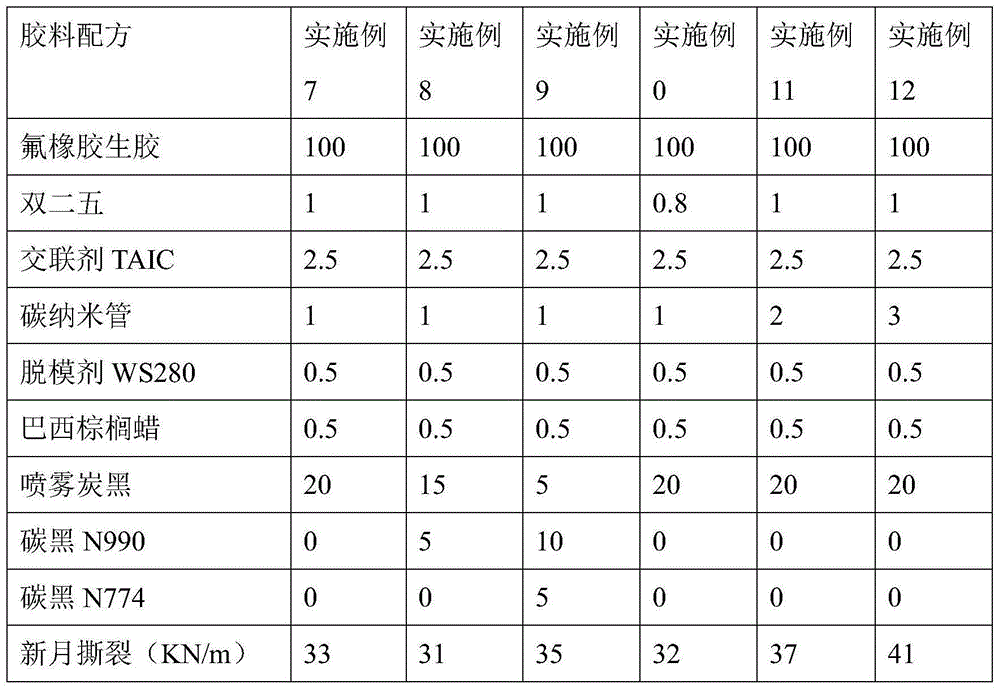

[0042] The present invention will be further described in detail below in conjunction with specific embodiments, but it should not be understood that the scope of the above subject of the present invention is limited to the following examples.

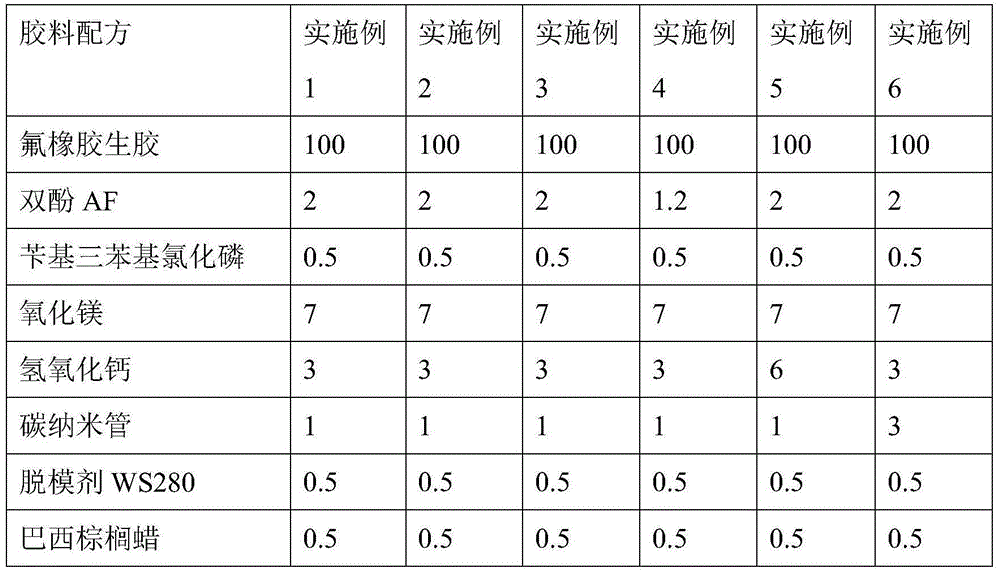

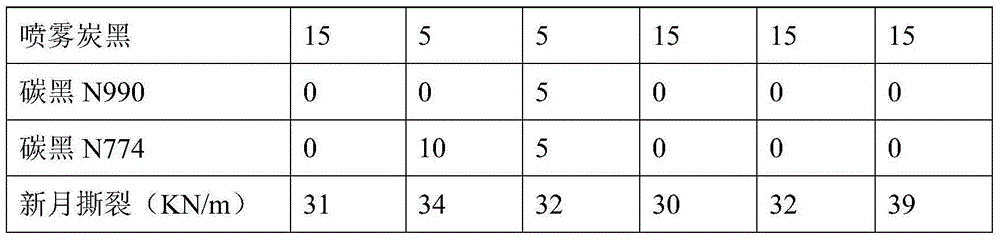

[0043] Examples 1-6 are rubber compounds prepared by using different proportions of components in the bisphenol vulcanization system. Table 1 shows the specific composition and the formula composition and tear performance of the examples with different component contents.

[0044] The preparation method of Examples 1-6 is as follows: firstly weigh binary or ternary fluororubber raw rubber and auxiliary agents in the formulation according to the ratio of parts by weight, and the auxiliary agents are bisphenol AF, benzyl triphenyl chloride Phosphorus, magnesium oxide, calcium hydroxide, carbon nanotubes, release agent WS280, carnauba wax, carbon black, and mix the additives evenly. Then the fluororubber raw rubber is masticated in the in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com