Cyanate ester adhesive with low dielectrics and high toughness, and preparation method thereof

A cyanate ester, high toughness technology, applied in adhesives and other directions, can solve the problems of reducing the dielectric properties of cyanate esters, environmental pollution, harsh conditions for fluorinated cyanate esters, etc., and achieves short curing time, low curing temperature, and equipment. less demanding effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

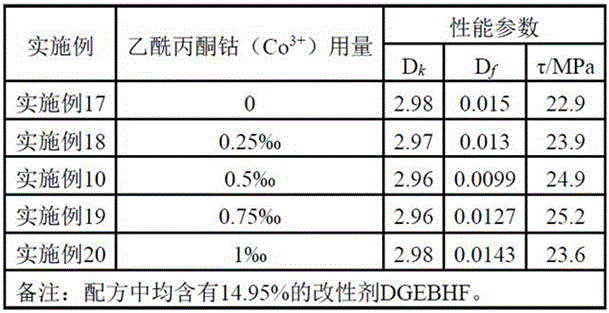

[0025] Weigh a certain amount of bisphenol A cyanate and fully melt it at 110-115 °C, then cool it down to 80-85 °C, add 0.5‰ cobalt acetylacetonate (Co 3+ ), after fully stirring and mixing, the cyanate ester adhesive was prepared. The specific performance is shown in Table 1.

Embodiment 2

[0027] Weigh a certain amount of bisphenol F type cyanate and fully melt it at 110-115 °C, then cool it down to 80-85 °C, add 0.5‰ cobalt acetylacetonate (Co 3+ ), after fully stirring and mixing, the cyanate ester adhesive was prepared. The specific performance is shown in Table 1.

Embodiment 3

[0029] Weigh a certain amount of bisphenol E-type cyanate and fully melt it at 110-115 °C, then cool it down to 80-85 °C, add 0.5‰ cobalt acetylacetonate (Co 3+ ), after fully stirring and mixing, the cyanate ester adhesive was prepared. The specific performance is shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

| dielectric loss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com