Modified fluororubber compounded stock and preparation method thereof

A technology for modifying fluororubber and fluororubber raw rubber, which is applied in the field of rubber compound preparation, which can solve the problem that the wear resistance and sealing performance need to be improved, the compression set of fluororubber is not mentioned, and the resistance of fluororubber is not mentioned. Grinding performance and other issues, to achieve good processability, improve mechanical properties, the effect of simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

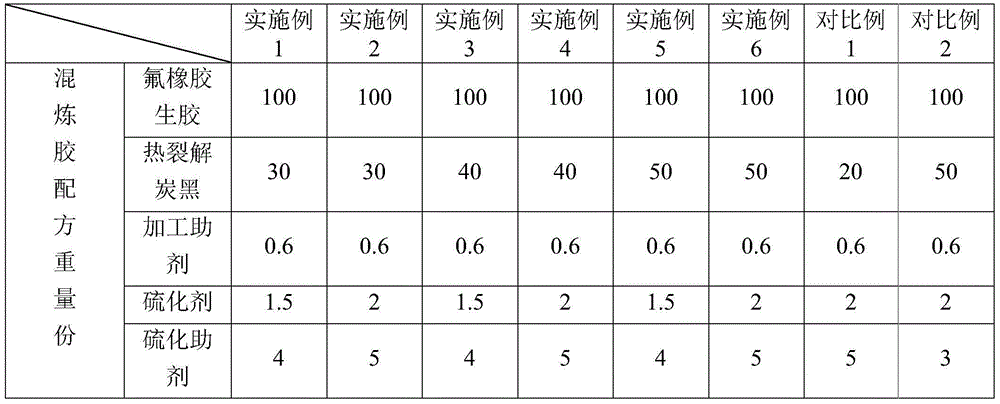

[0026] Configure the raw materials according to the formula in Table 1.

[0027] The operation steps are as follows: add fluororubber raw rubber to the open mill, roll temperature 40-50°C, roll speed 18-22rpm, adjust the roll distance, subject to the accumulation of rubber between the two rolls; add additives in order: ① Processing aid stearic acid, wear-resistant additive nano-silicon carbide, ② magnesium oxide, calcium hydroxide, ③ thermal cracking carbon black, high wear-resistant furnace black, ④ vulcanizing agent bisphenol AF, vulcanizing aid BPP; every step After the powder is completely eaten, cut 5 triangle buns with a knife, and roll for 1 minute. After the rubber is mixed evenly, the sheet will be thinned out 12 times, and the sheet will be left at room temperature for 18 hours; the temperature of the roll is controlled at 55 ° C, and the roll distance is 0.4 mm The roller speed is 24rpm, and the triangular bag thin pass is carried out for 12 times, and then the roll...

Embodiment 2

[0030] Configure the raw materials according to the formula in Table 1.

[0031] Operation steps Except that the processing aid is calcium stearate, and the wear-resisting additive is molybdenum selenide micropowder. After eating the powder, open 3 triangular bags with a knife, and roll for 2 minutes. It is the same as embodiment 1 except that it is 0.3 mm.

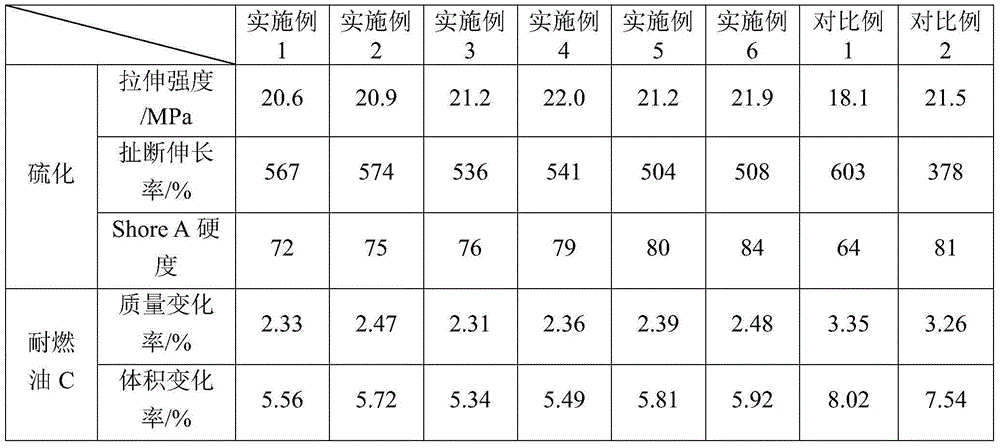

[0032] The performance test items are the same as in Example 1, and the results are shown in Table 2.

Embodiment 3

[0034] Configure the raw materials according to the formula in Table 1.

[0035] The operating steps are the same as in Example 1, except that the processing aid is carnauba wax, and a triangular bag is opened after the powder is completely eaten.

[0036] Performance test item is the same as embodiment 1, and the results are shown in Table 2

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com