Polyphosphazene microsphere as well as preparation method, and application and implementation method thereof

A polyphosphazene and microsphere technology, applied in the field of materials, can solve the problems of high cost and difficult synthesis, and achieve the effects of low cost, simple process and excellent thermal stability

Inactive Publication Date: 2010-11-03

SHANGHAI JIAO TONG UNIV

View PDF0 Cites 12 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Found through literature search to prior art, Ocock et al. published "poly[two (2,2,2-trifluoroethoxyl groups] in No. 11604~11607, No. 25, No. 25, Volume 21, 2005 of "Langmuir" in 2005 ) Phosphazene] Superhydrophobic Nanofibers" (A.Singh, L.Steelyand H.R.Allcock, Poly[bis(2,2,2-trifluoroethoxy)phosphazene]Superhydrophobic Nanofibers, Langmuir, 2005, 21(25): 11604~11607) In one article, a superhydrophobic poly[bis(2,2,2-trifluoroethoxy)phosphazene] nanofiber was reported, but the preparation process of the fiber must rely on electrospinning technology, and the polyphosphazene material used It is a linear polymer, which is difficult and expensive to synthesize

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Login to View More

Abstract

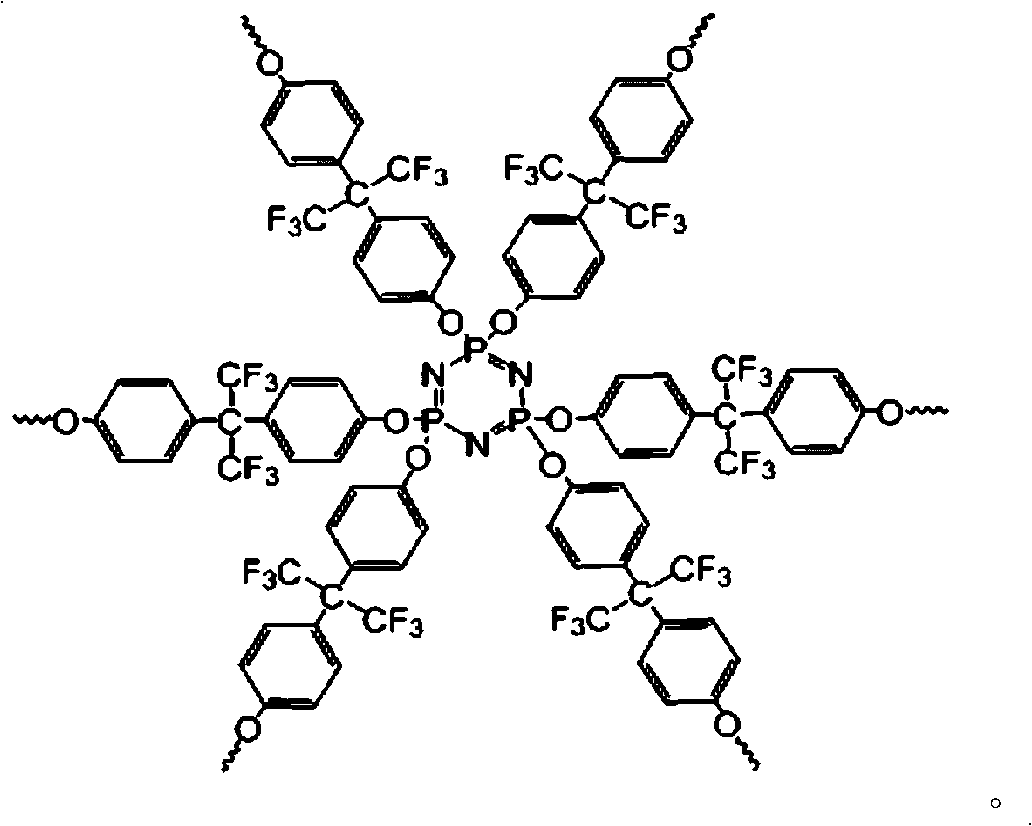

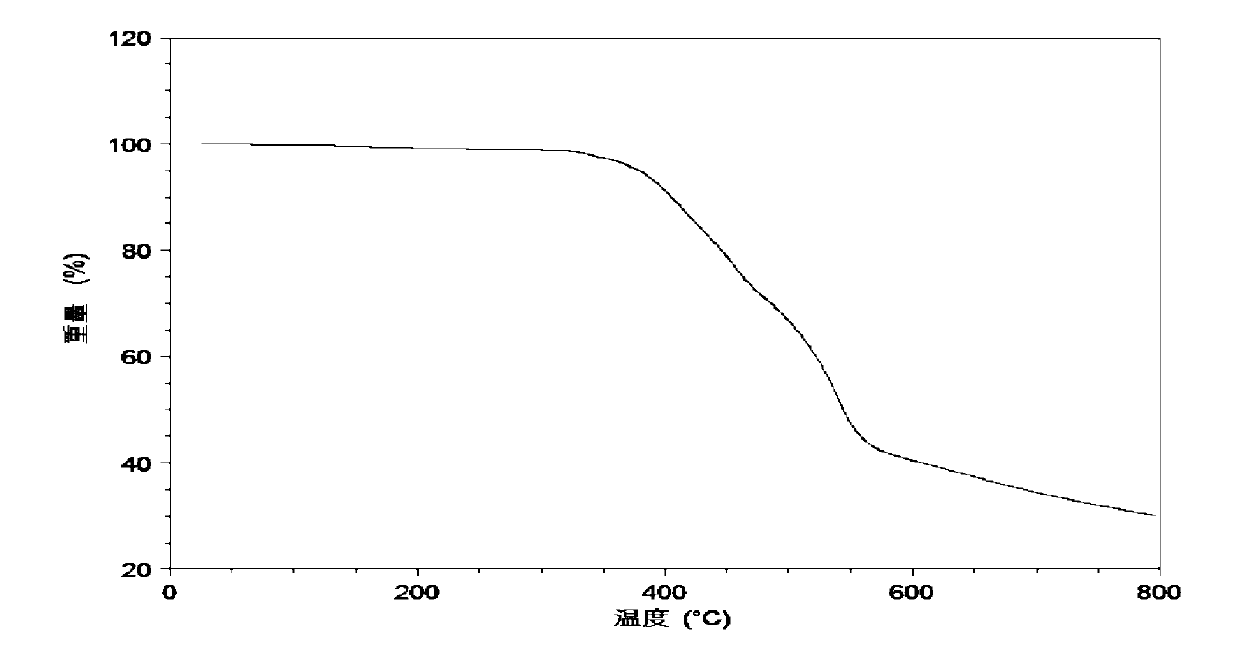

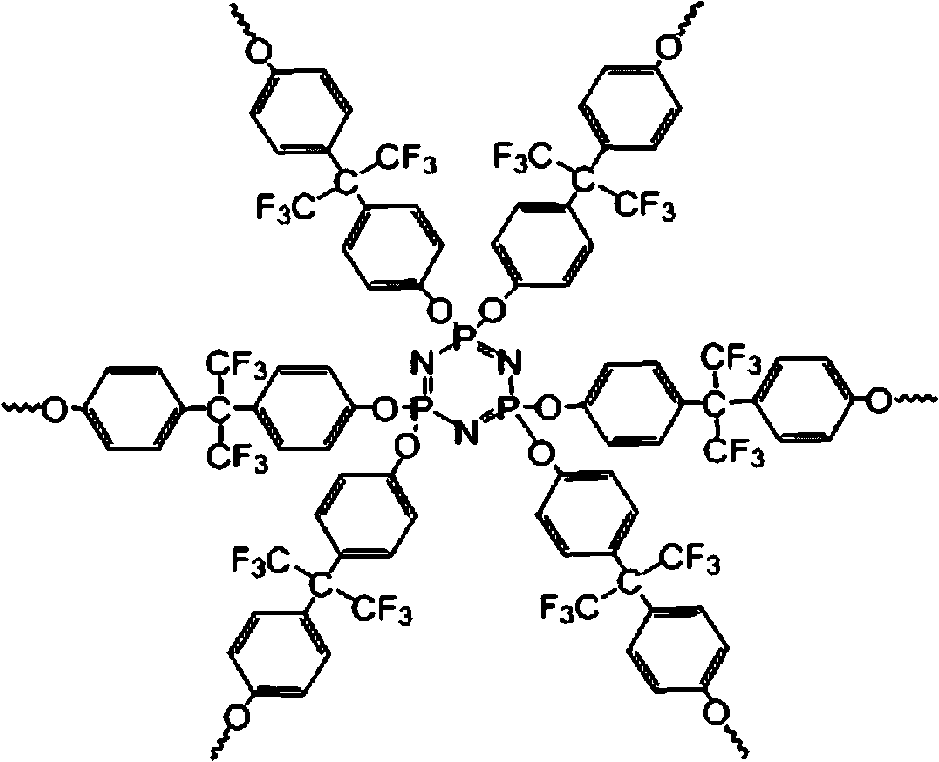

The invention relates to a polyphosphazene microsphere as well as a preparation method and an application thereof in the technical field of materials. The polyphosphazene microsphere has the structural formula as disclosed in the specification. The preparation method of the polyphosphazene microsphere comprises the following steps of: (1) in the presence of an acid binding agent and an organic solvent, carrying out polycondensation reaction on hexachlorocyclotriphosphazene and bisphenol AF to obtain a solution; (2) and filtering the solution, washing a filtering medium, and drying to obtain the polyphosphazene microsphere. The invention also relates to application of the polyphosphazene microsphere in the preparation of a super-hydrophobic surface. The polyphosphazene microsphere has the advantages of low cost, excellent thermostability, flame retardance, chemical durability and radiation resistance. The preparation method has the advantages of short time, mild reaction conditions and simple process. The super-hydrophobic surface prepared from the polyphosphazene microsphere has excellent super-hydrophobicity.

Description

technical field The invention relates to a microsphere in the technical field of materials and a preparation method, use and realization method thereof, in particular to a polyphosphazene microsphere and a preparation method, use and realization method thereof. Background technique Surfaces with a water contact angle >150° are called superhydrophobic surfaces. Since its recognition in the 1940s, superhydrophobic surfaces have attracted widespread attention and have been widely used in self-cleaning materials, antifouling materials, and water-repellent materials. Many organisms in nature exhibit interesting superhydrophobic phenomena, such as water mosquitoes, geckos and lotus leaves. Especially for lotus leaves, studies have shown that its superhydrophobicity is the result of the combined action of the micro / nano secondary structure on the surface of lotus leaves and the waxy low surface energy substances on the surface. Inspired by this basic principle, artificial supe...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C08G79/02B01J13/14C09D185/02C08G79/025

Inventor 黄小彬魏玮赵晓莉陈奎永唐小真

Owner SHANGHAI JIAO TONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com