Method for realizing catalytic synthesis of bisphenol F by virtue of flaky Al-SBA-15 mesoporous molecular sieve

A technology of mesoporous molecular sieve, al-sba-15, which is applied in the direction of molecular sieve catalysts, chemical instruments and methods, and the preparation of organic compounds, etc., to achieve the effects of low preparation cost, high catalytic activity, and easy separation and recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

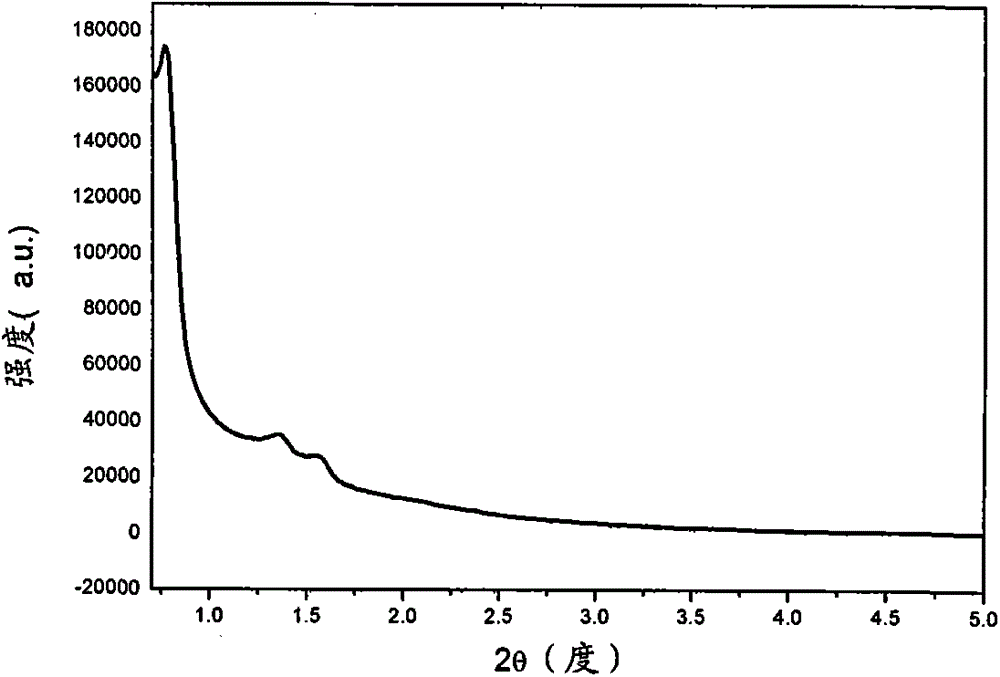

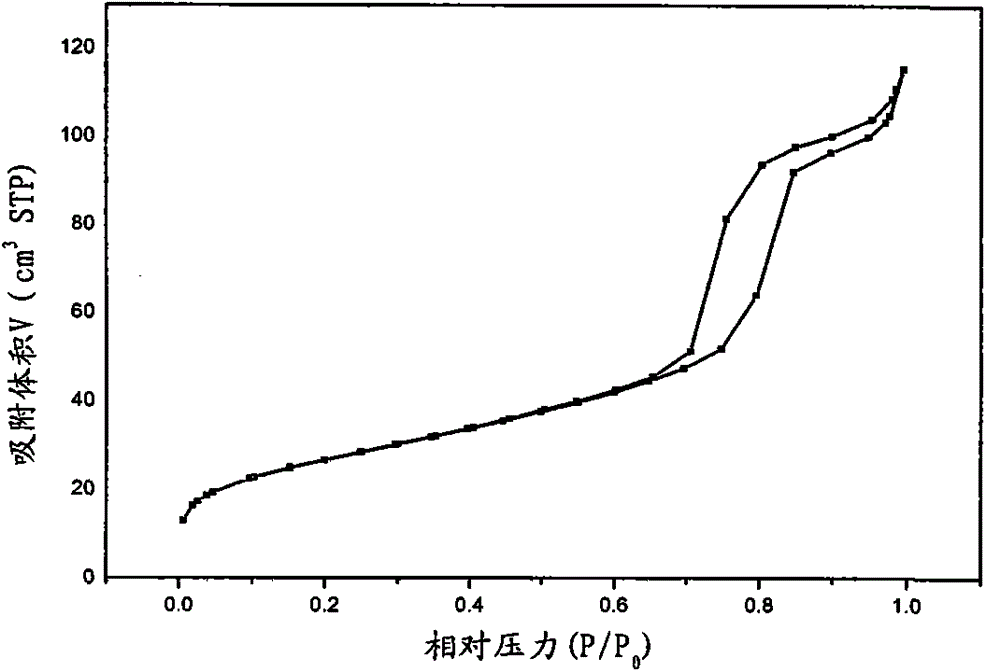

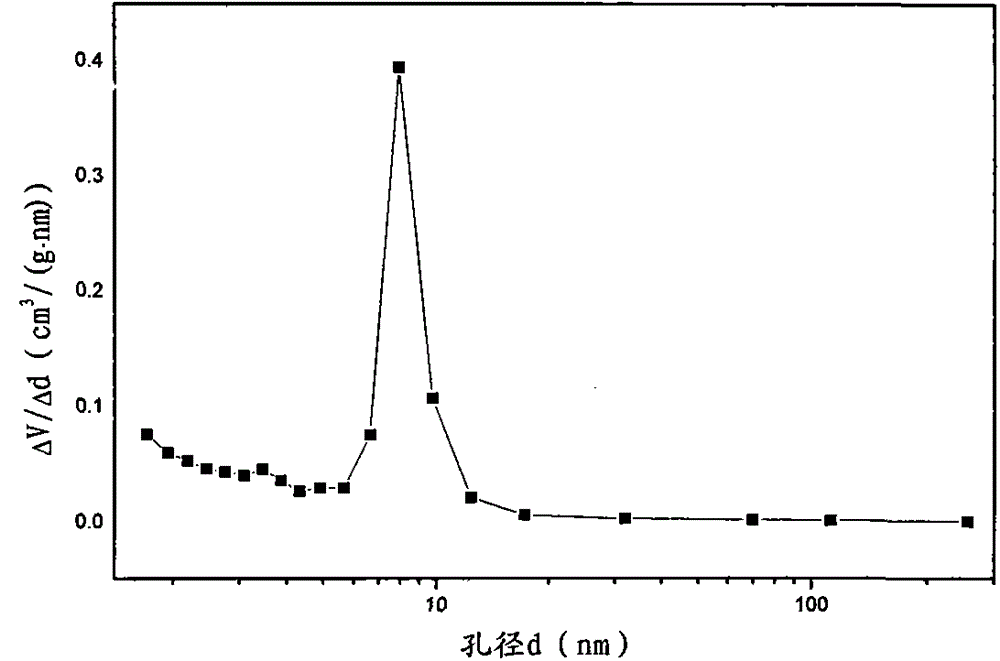

[0028] (1) Preparation of flake Al-SBA-15 mesoporous molecular sieve catalyst

[0029] Step 1: Add 9 grams of tetraethyl orthosilicate and 0.44 grams of aluminum isopropoxide to 20 mL of 0.03 mol / L hydrochloric acid solution, fully stir and dissolve into solution A, add 4 grams of Pluronic123 and 0.64 grams of zirconium oxychloride to In 140mL of 0.03mol / L hydrochloric acid solution, fully stir and dissolve to form solution B, and slowly add solution A to solution B under sufficient stirring conditions to obtain mixture C;

[0030] The second step: Stir the mixture C obtained in the first step at 35°C for 24 hours, then transfer it to a polytetrafluoroethylene-lined hydrothermal kettle, stand at 100°C for crystallization for 48 hours, filter, and wash the filter cake with water for 3 times , dried, and calcined at 550° C. for 6 hours to obtain 3 grams of sheet-like Al-SBA-15 mesoporous molecular sieve catalyst, wherein the Si / Al molar ratio of the catalyst was 20:1.

[0031] ...

Embodiment 2

[0041] With embodiment 1, its difference is that aluminum isopropoxide consumption is 0.176 gram in the first step of preparing flake Al-SBA-15 mesoporous molecular sieve catalyst, the prepared flake Al-SBA-15 mesoporous molecular sieve catalyst Si / Al molar ratio is 50:1, and the yield of bisphenol F is 80.6%.

Embodiment 3

[0043] With embodiment 1, its difference is that in the first step of preparing sheet-like Al-SBA-15 mesoporous molecular sieve catalyst, aluminum isopropoxide consumption is 1.76 grams, the Si of prepared sheet-like Al-SBA-15 mesoporous molecular sieve catalyst The / Al molar ratio was 5:1, and the yield of bisphenol F was 80.5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com