Processing method of lignite

A processing method and technology for lignite, which are applied in chemical instruments and methods, preparation of organic compounds, preparation of liquid hydrocarbon mixtures, etc., can solve the problems of harsh operating conditions, high equipment requirements, and high cost, and achieve a high degree of localization. The effect of high liquefied oil yield and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

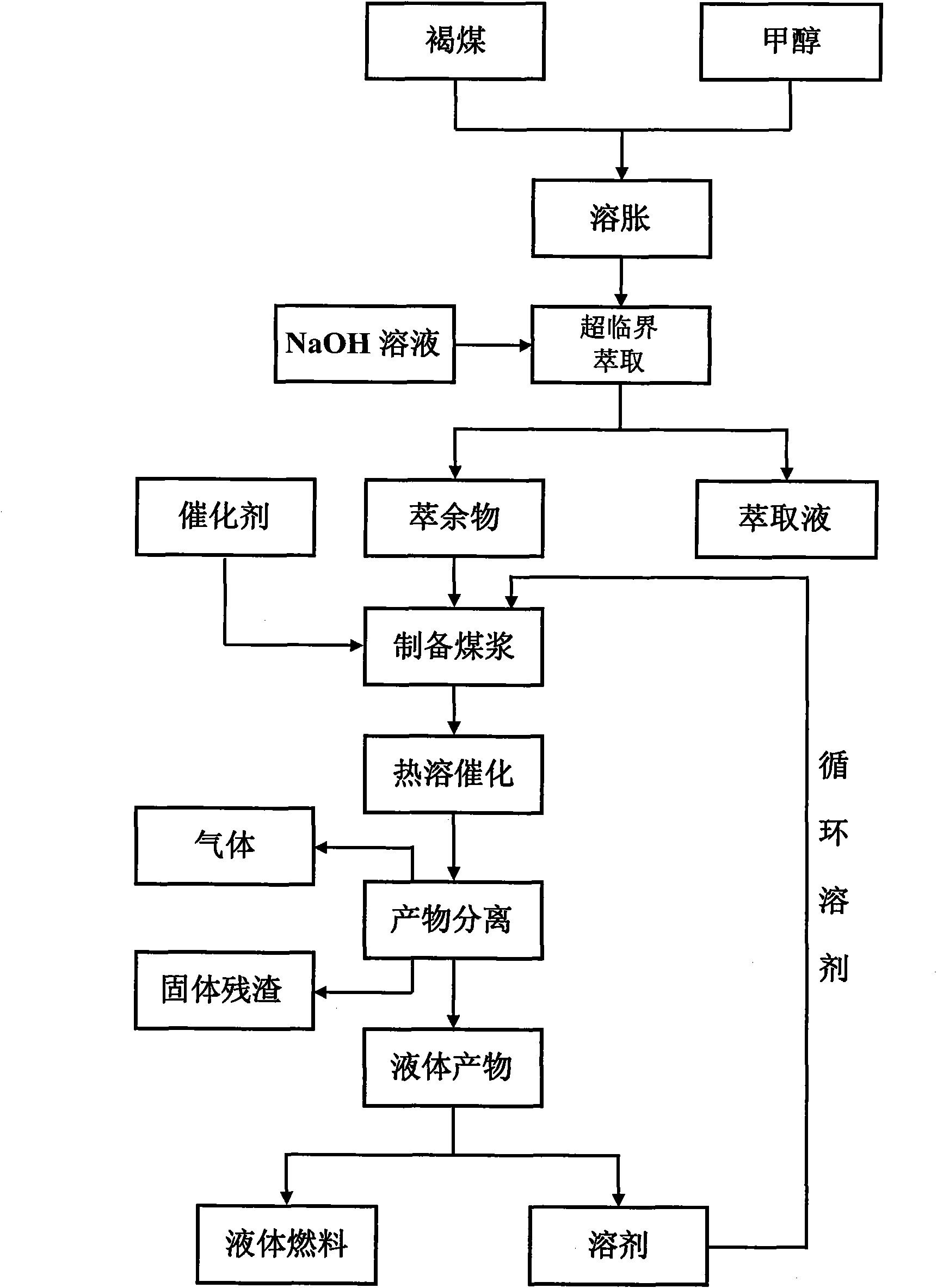

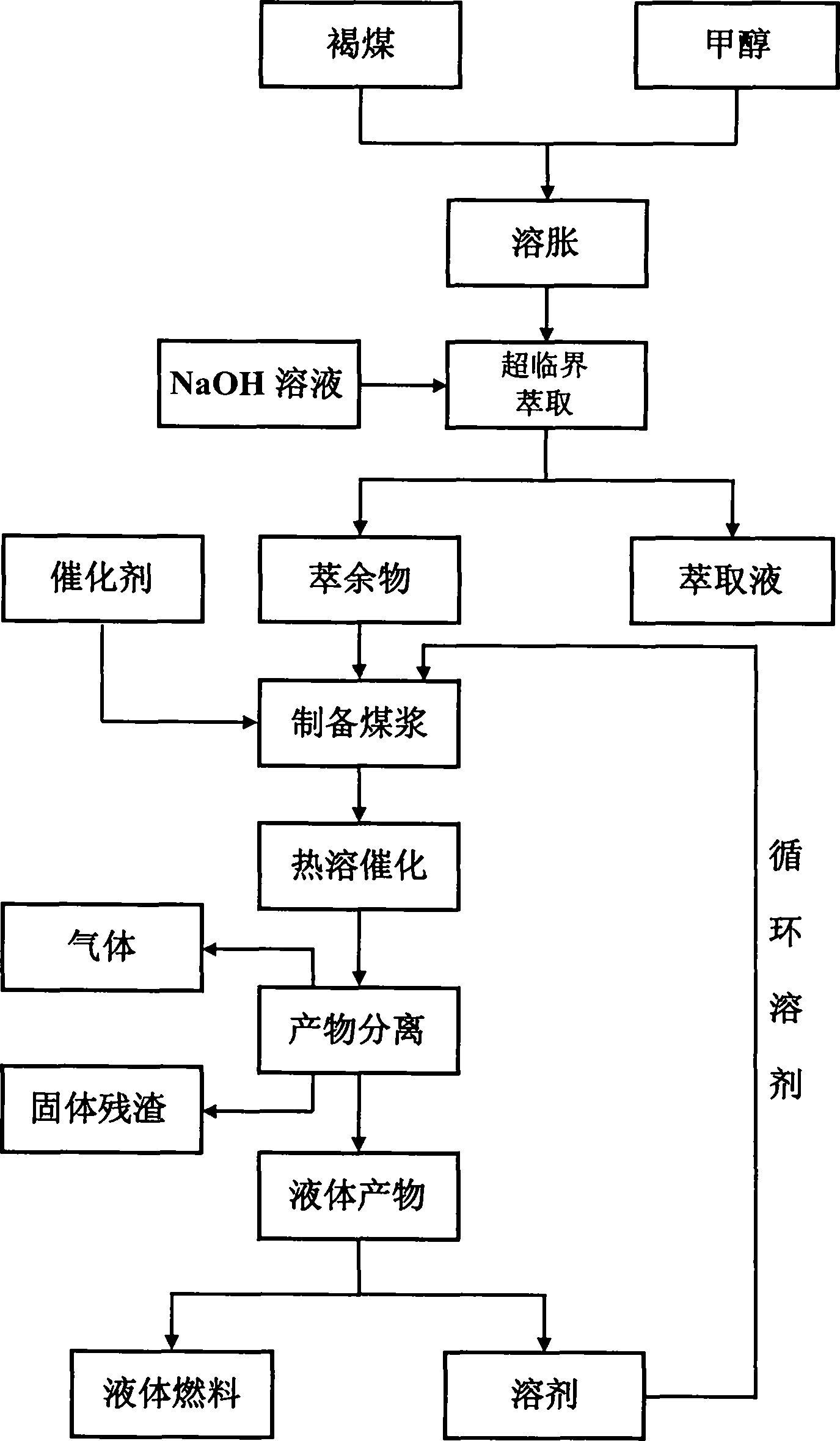

[0020] Such as figure 1 As shown, the lignite and methanol are mixed and soaked according to the mass ratio of 1:3, and the swelling pretreatment is carried out at normal temperature and pressure. After 4 hours of swelling pretreatment, the pH of the swollen mixture was adjusted to 8.0 with NaOH solution, and supercritical methanol extraction was carried out under the supercritical conditions of extraction temperature 260°C and pressure 9.0MPa, and the extraction time was 60 minutes to obtain the extract and raffinate The conversion of lignite to crude phenol, methyl organic acid and humic acid in this section can reach 21.31% (daf).

[0021] The raffinate is prepared into coal slurry, which is subjected to hot-melt catalytic liquefaction treatment (see ZL200710032428.4 for the specific process of hot-melt catalytic liquefaction, which discloses a hot-melt catalytic method for producing liquid fuel from lignite), and the yield of liquefied oil is 31.13% (daf), the total produ...

Embodiment 2

[0026] The lignite and methanol are mixed and soaked according to the mass ratio of 1:2, and the swelling pretreatment is carried out at normal temperature and pressure. After 4 hours of swelling pretreatment, adjust the pH of the swollen mixture to 8.0 with NaOH solution, and perform supercritical methanol extraction under the supercritical conditions of extraction temperature 260 ° C and pressure 9.0 MPa, and the extraction time is 60 minutes to obtain the extract and raffinate The conversion rate of lignite to crude phenol, organic acid methyl ester and humic acid reaches 16.24% (daf).

[0027] The raffinate is prepared into coal slurry, which is subjected to thermal solution catalytic liquefaction treatment, and the yield of liquefied oil is 32.06% (daf), and the total product yield reaches 43.09%. Compared with the single-stage hot-melt catalytic liquefaction in this embodiment, the total product yield has increased by about 12%; hydrogen consumption has been saved by abo...

Embodiment 3

[0032] The lignite and methanol are mixed and soaked according to the mass ratio of 1:5, and the swelling pretreatment is carried out at normal temperature and pressure. After 4 hours of swelling pretreatment, adjust the pH of the swollen mixture to 8.0 with NaOH solution, and perform supercritical methanol extraction under the supercritical conditions of extraction temperature 260 ° C and pressure 9.0 MPa, and the extraction time is 60 minutes to obtain the extract and raffinate The conversion rate of lignite to crude phenol, organic acid methyl ester and humic acid is 23.06% (daf).

[0033] The raffinate is prepared into coal slurry, which is subjected to thermal solution catalytic liquefaction treatment, and the yield of liquefied oil is 30.69% (daf), and the total product yield reaches 46.67%. Compared with the single-stage hot-melt catalytic liquefaction in this embodiment, the total product yield has increased by about 15%; hydrogen consumption has been saved by about 23...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com