Electrochemical oxidation device

An oxidation device and electrochemical technology, applied in the direction of sterilization/microdynamic water/sewage treatment, etc., can solve the problems of increased treatment cost, increased system processing capacity, environmental hazards, etc., to improve biodegradability and strengthen electrochemical Degradation effect, effect of reducing chroma

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

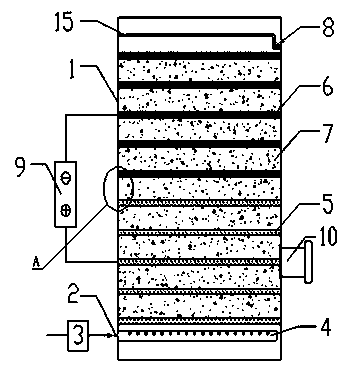

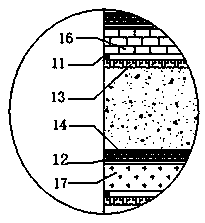

[0038] The electrochemical oxidation device in this embodiment includes a housing 1, a water inlet 2, a liquid distributor 4, an anode bed 5, a cathode bed 6, a micro-electrolysis packing layer 7, a water outlet 8, a power supply 9, a packing outlet 10, a packing The pressure plate 13, the overflow weir 15, the water inlet 2 is set at the lower part of the shell 1, the liquid distributor 4 is set at the water inlet, the anode bed 5 with more than 4 layers is set above the liquid distributor 4, and the anode bed 5 is set 4 The cathode bed 6 above the layer, the anode bed 5 or the cathode bed 6 are arranged on the packing plate 13, the micro-electrolysis packing layer 7 is filled between the anode bed or the cathode bed and the packing plate 13, and the overflow weir 15 is arranged on the shell 1 On the inner wall, the overflow weir 15 is set on the shell 1, and the water outlet 8 is set on the shell 1, which is higher than the bottom of the overflow weir 15 in the vertical direc...

Embodiment 2

[0056]The electrochemical oxidation device in this embodiment includes a housing 1, a water inlet 2, a liquid distributor 4, an anode bed 5, a cathode bed 6, a micro-electrolysis packing layer 7, a water outlet 8, a power supply 9, a packing outlet 10, a packing The pressure plate 13, the overflow weir 15, the water inlet 2 is set at the lower part of the shell 1, the liquid distributor 4 is set at the water inlet, the anode bed 5 with more than 4 layers is set above the liquid distributor 4, and the anode bed 5 is set 4 The cathode bed 6 above the layer, the anode bed 5 or the cathode bed 6 are arranged on the packing plate 13, the micro-electrolysis packing layer 7 is filled between the anode bed or the cathode bed and the packing plate 13, and the overflow weir 15 is arranged on the shell 1 On the inner wall, the overflow weir 15 is set on the shell 1, and the water outlet 8 is set on the shell 1, which is higher than the bottom of the overflow weir 15 in the vertical direct...

Embodiment 3

[0074] The electrochemical oxidation device in this embodiment includes a housing 1, a water inlet 2, a liquid distributor 4, an anode bed 5, a cathode bed 6, a micro-electrolysis packing layer 7, a water outlet 8, a power supply 9, a packing outlet 10, a packing The pressure plate 13, the overflow weir 15, the water inlet 2 is set at the lower part of the shell 1, the liquid distributor 4 is set at the water inlet, the anode bed 5 with more than 4 layers is set above the liquid distributor 4, and the anode bed 5 is set 4 The cathode bed 6 above the layer, the anode bed 5 or the cathode bed 6 are arranged on the packing plate 13, the micro-electrolysis packing layer 7 is filled between the anode bed or the cathode bed and the packing plate 13, and the overflow weir 15 is arranged on the shell 1 On the inner wall, the overflow weir 15 is set on the shell 1, and the water outlet 8 is set on the shell 1, which is higher than the bottom of the overflow weir 15 in the vertical direc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com