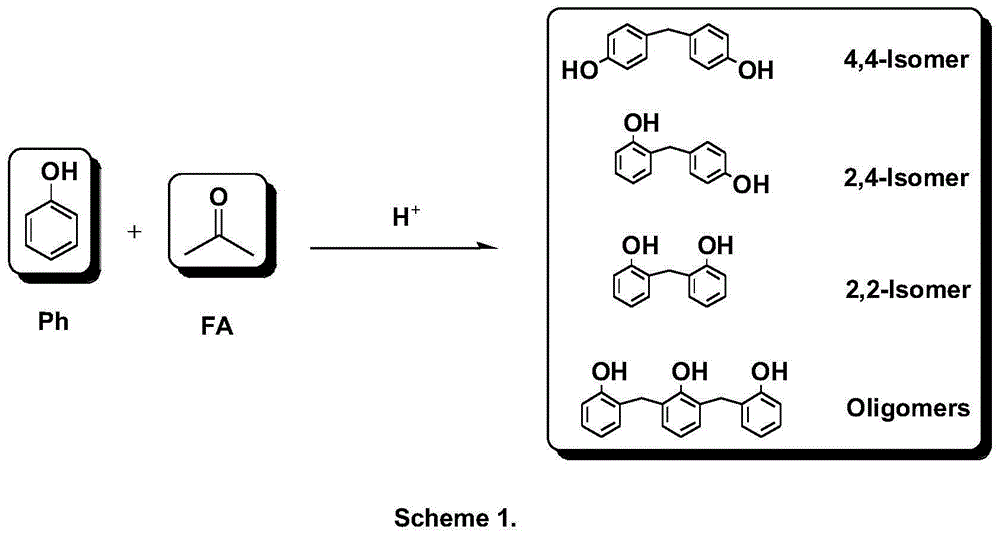

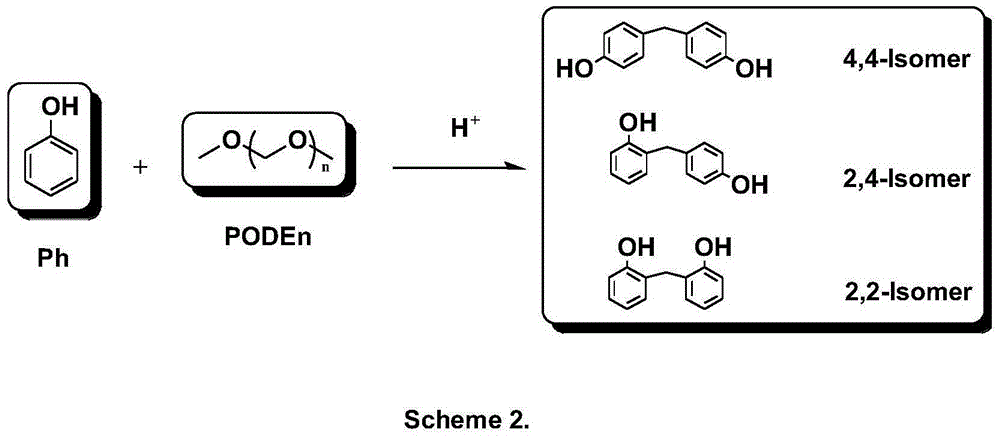

Method for preparing bisphenol F by adopting polyoxymethylene dimethyl ethers as raw material

A technology of dimethyl ether and paraformaldehyde, applied in chemical instruments and methods, preparation of organic compounds, production of bulk chemicals, etc., can solve the impact of unseen yield and selectivity reports, heat transfer and mass transfer , limit further use and other issues, to achieve high yield, easy control, high selectivity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

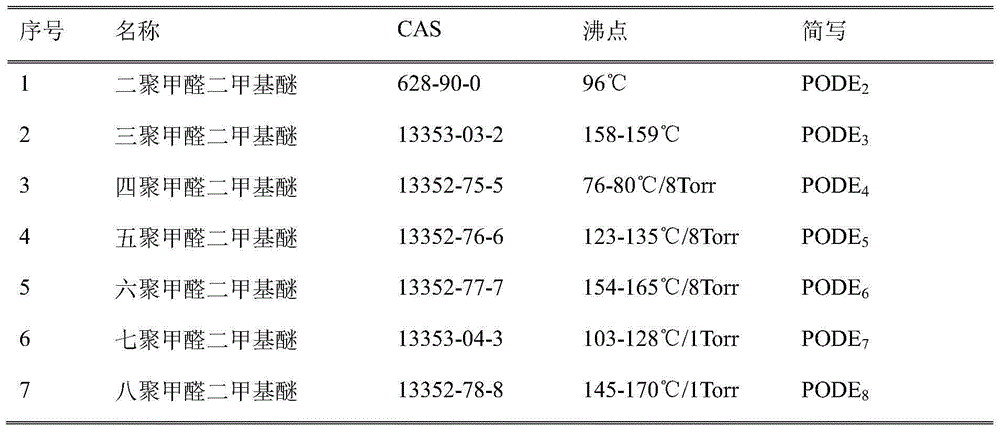

Embodiment 1

[0032] Add phenol (the mol ratio of phenol and paraformaldehyde dimethyl ether is 15:1), phosphoric acid (the mol ratio of phosphoric acid and paraformaldehyde dimethyl ether is 6.4:1) and Water (the molar ratio of water and paraformaldehyde dimethyl ether is 14:1), the water bath is slowly heated to 80 ° C, and then slowly add 5 grams of paraformaldehyde dimethyl ether dropwise therein, and the temperature is controlled at 75 Between ℃-85℃. After dropping, keep the temperature at 80°C and continue the reaction for 4h. After the reaction of the raw materials is completed, the temperature is naturally lowered to 45°C, the reaction solution is poured into a separatory funnel, allowed to stand for stratification, and the phosphoric acid aqueous solution in the lower layer is recovered and used mechanically. The upper organic phase was neutralized by alkali, then concentrated under reduced pressure, and the excess phenol was recovered and used mechanically. The concentrated solu...

Embodiment 2

[0036] Add 90 grams of phenol (phenol and PODE 2 The molar ratio of 20.3:1), 6 grams of water (water and PODE 2 The mol ratio is 7.1:1) and 15 grams of solid acid catalyst (I, catalyst and PODE 2 The mass ratio of the water bath is 3:1), the water bath is slowly heated to 85 °C, and then 5 grams of PODE is slowly added dropwise to it 2 , Control the temperature at around 85°C during the dropwise addition. After dropping, keep the temperature at 85°C and continue the reaction for 16h. After the reaction of the raw materials is completed, the temperature is naturally lowered to 45° C., suction filtered, the solid acid catalyst in the upper layer is recovered and used mechanically, the filtrate in the lower layer is concentrated under reduced pressure, and excess phenol is recovered and used mechanically. The concentrated solution was diluted with ethyl acetate, washed with saturated ammonium chloride aqueous solution and water successively, dried over anhydrous sodium sulfate...

Embodiment 3

[0045] Add 26 grams of phenol (phenol and PODE 2 The molar ratio of 5.87:1), 6 grams of water (water and PODE 2 The molar ratio is 7.1:1) and 1.2 grams of solid acid catalyst (II, catalyst and PODE 2 The mass ratio is 0.24:1), the water bath is slowly heated to 80°C, and then 5 grams of PODE is slowly added dropwise to it 2 , Control the temperature at around 80°C during the dropwise addition. After dropping, keep the temperature at 80°C and continue the reaction for 4h. After the reaction of the raw materials is completed, the temperature is naturally lowered to 45° C., suction filtered, the solid acid catalyst in the upper layer is recovered and used mechanically, the filtrate in the lower layer is concentrated under reduced pressure, and excess phenol is recovered and used mechanically. The concentrated solution was diluted with anhydrous ether, washed with saturated ammonium chloride aqueous solution and water successively, dried over anhydrous sodium sulfate, filtered ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com