Macroreticular resin capable of lowering content of phenyl hydroxide in cigarette smoke and preparation method thereof

A cigarette smoke and pore adsorption technology, applied in chemical instruments and methods, other chemical processes, etc., can solve the problem of reducing phenol release, achieve the effect of reducing pollution and improving adsorption rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

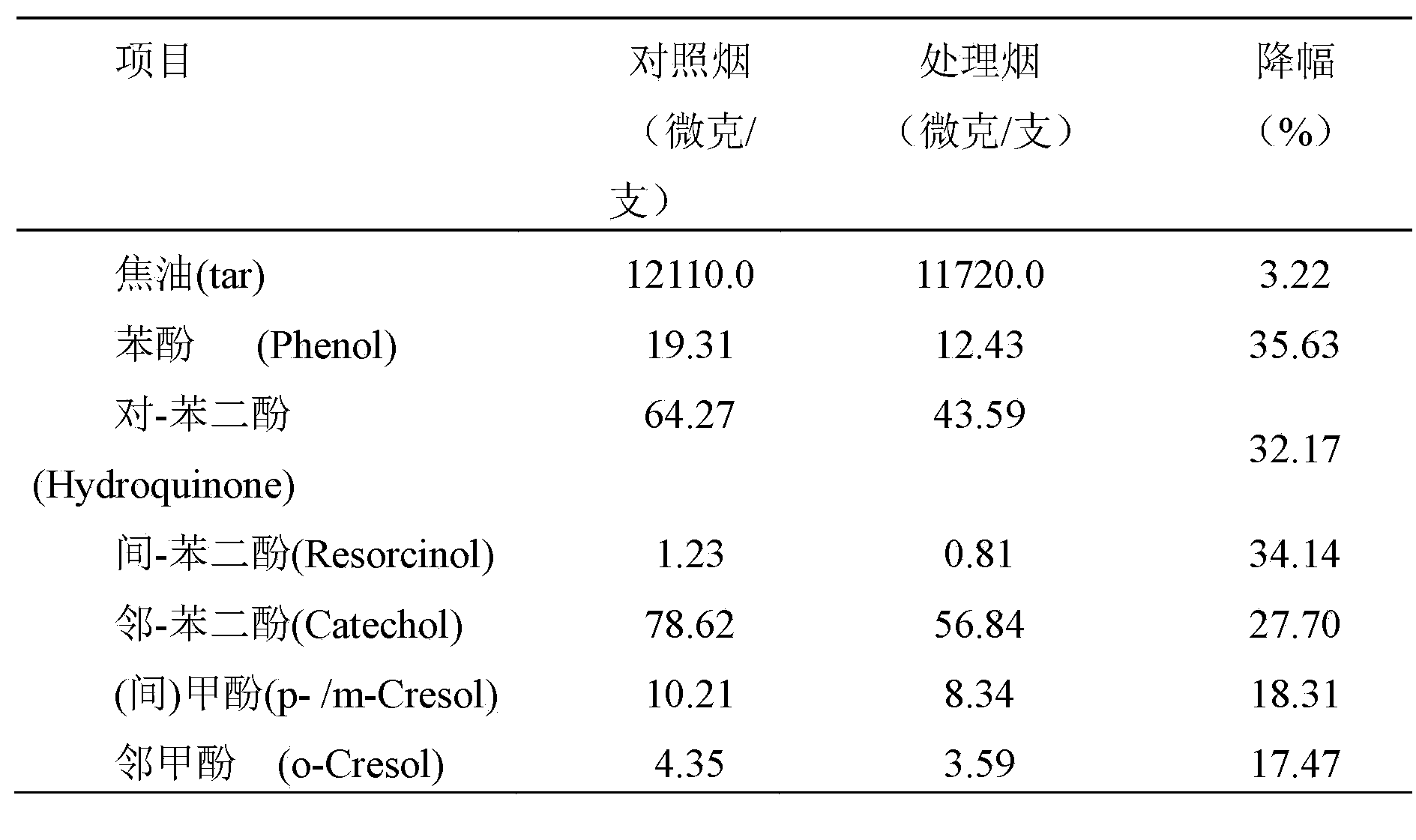

Examples

Embodiment 1

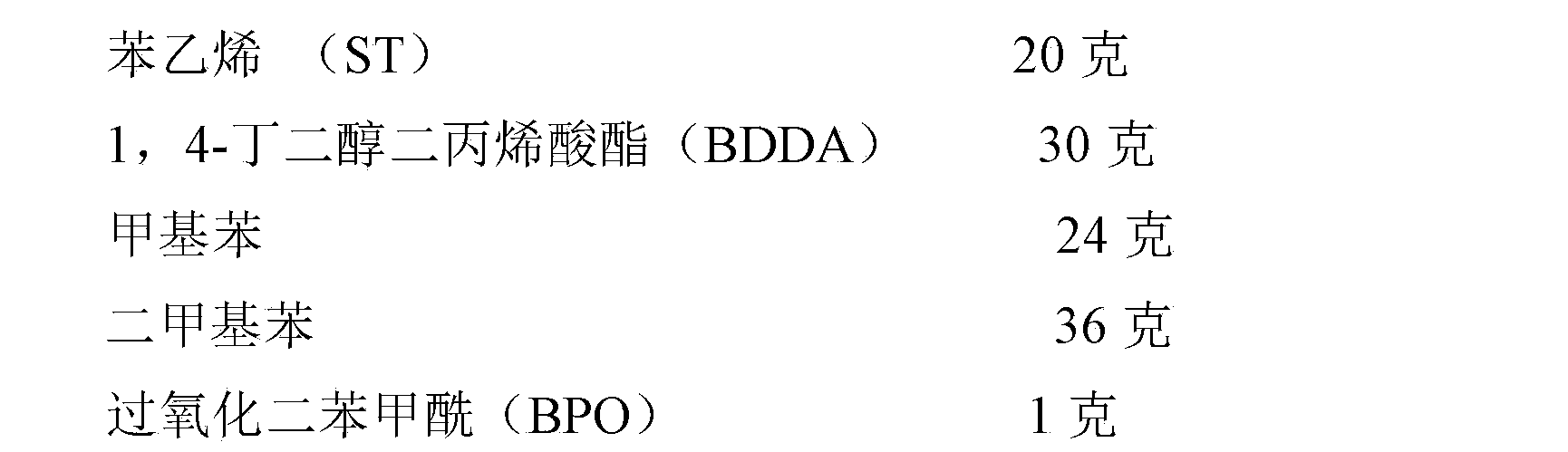

[0036] In parts by weight, the macroporous adsorption resin contains the following components:

[0037] Oil phase

[0038]

[0039] water box

[0040] 400g deionized water

[0041] Polyvinyl alcohol (PVA) 3 grams

[0042] NaCl 30g

[0043] The porogen is methylbenzene and dimethylbenzene are mixed in a mass ratio of 4:6.

[0044] The specific process of the preparation method of the macroporous adsorption resin is as follows:

[0045] (1) According to the synthetic formula of the macroporous adsorption resin, accurately weigh NaCl and deionized water into a three-necked reaction vessel, and stir at 30-40 rpm (revolutions per minute);

[0046] (2) Place the reaction vessel in an oil bath and raise the temperature to 60°C, add polyvinyl alcohol (PVA), this system is water phase;

[0047] (3) Accurately weigh styrene, 1,4-butanediol diacrylate (BDDA), porogen and dibenzoyl peroxide (BPO) according to the synthetic formula of the macroporous adsorption resin, and mix them evenly into the oil pha...

Embodiment 2

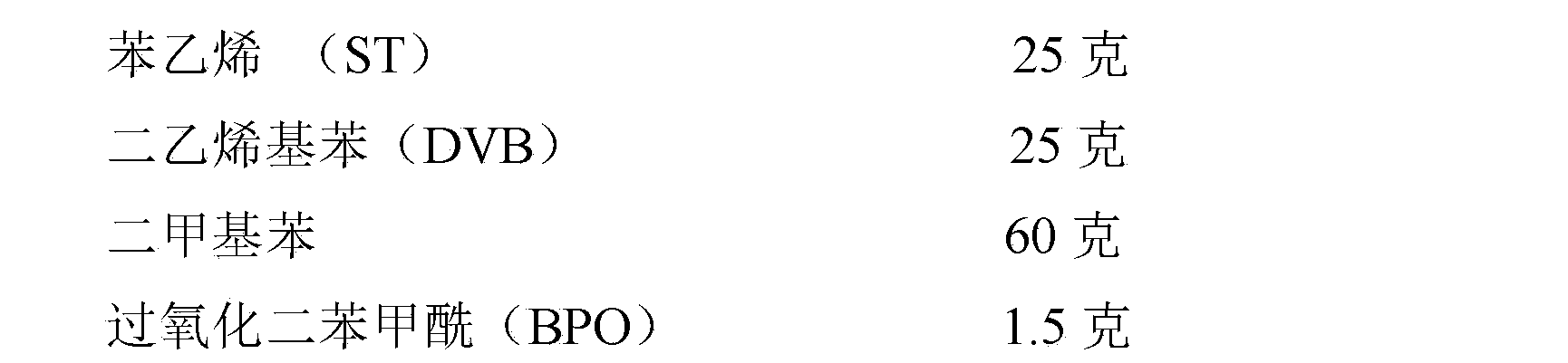

[0058] In parts by weight, the macroporous adsorption resin contains the following components:

[0059] Oil phase

[0060]

[0061] water box

[0062] 400g deionized water

[0063] Polyvinyl alcohol (PVA) 3 grams

[0064] NaCl 30g

[0065] According to the synthetic formula of the macroporous adsorption resin of the present invention, accurately weigh 30 grams of NaCl and 400 grams of deionized water into a three-necked reaction vessel, stir at 30-40 rpm (revolutions per minute); place the reaction vessel in an oil bath Heat up the pot to 60°C, add 3 grams of PVA, the system is the water phase; accurately weigh 25 grams of styrene (ST), 25 grams of 80% divinylbenzene (DVB), dimethyl 60 grams of base benzene and 1.5 grams of dibenzoyl peroxide (BPO), mix evenly into the oil phase, then pour it into the water phase, heat up to 70°C for polymerization, and speed up the stirring speed of the reactor to 40-50rpm , To make the small droplets formed by the oil phase uniformly dispersed in th...

Embodiment 3

[0071] In parts by weight, the macroporous adsorption resin contains the following components:

[0072] Oil phase

[0073]

[0074] water box

[0075] 400g deionized water

[0076] Polyvinyl alcohol (PVA) 3 grams

[0077] NaCl 30g

[0078] According to the synthetic formula of the macroporous adsorption resin, accurately weigh 30 grams of NaCl and 400 grams of deionized water into a three-neck reaction vessel, stir at 30-40 rpm (revolutions per minute); place the reaction vessel in an oil bath Heat up to 60℃, add 3 grams of PVA, this system is the water phase; accurately weigh 28 grams of styrene (ST) and 22 grams of 1,4-butanediol diacrylate (BDDA) according to the macroporous adsorption resin synthesis formula. 60 grams of dimethylbenzene and 2 grams of azobisisobutyronitrile (AIBN) are mixed uniformly into the oil phase, and then poured into the water phase, heated to 70°C for polymerization reaction, and at the same time accelerate the stirring speed of the reactor to 40 -50rpm to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com