Pyrolyzation and debromination method of waste printed circuit board

A circuit board and waste printing technology, which is applied in the field of pyrolysis and debromination of non-metallic components, can solve the problems of unfavorable comprehensive utilization, achieve the effect of improving the effective utilization rate and curbing the formation of harmful components of dioxin

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

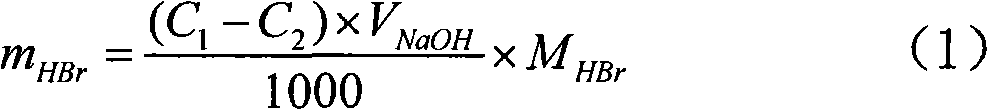

Method used

Image

Examples

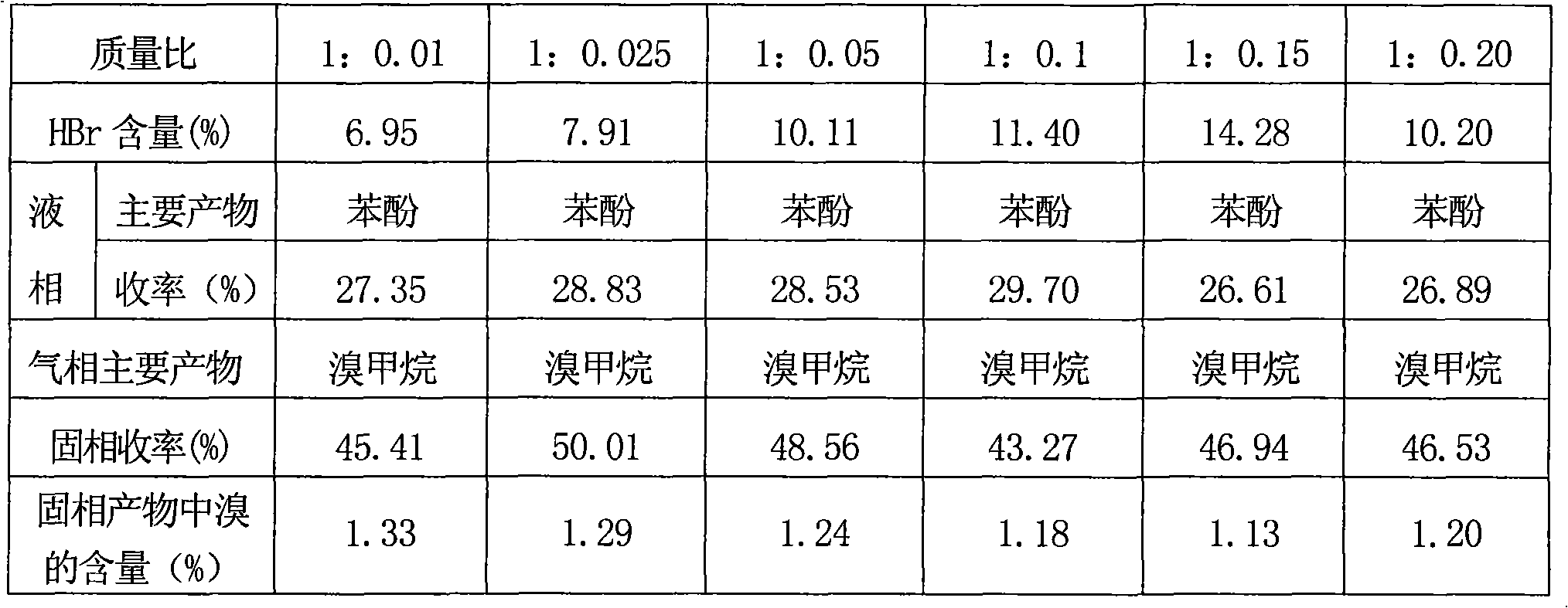

Embodiment 1

[0025] 1. Separation of non-metallic objects from waste printed circuit boards

[0026] Sequentially use a hammer crusher, shredder, rotary crusher, and ball mill to crush waste circuit boards into particles smaller than 1mm, use a low-strength magnetic separator to separate ferromagnetic substances, and then separate the broken circuit boards by electrostatic separation The metal in the product except the ferromagnetic substance is the non-metallic separation of the waste printed circuit board, and the resin content is more than 70%.

[0027] 2. Pyrolysis reaction

[0028] Join the non-metallic separator 100g and hexamethylenetetramine 15g of the remaining waste printed circuit board in step 1 in the rotary furnace reactor, the quality of the nonmetallic separator and hexamethylenetetramine of the waste printed circuit board The ratio is 1:0.15, in N 2 N at a flow rate of 20mL / min 2 In the atmosphere, the temperature was raised to 150°C at a heating rate of 2°C / min, cured ...

Embodiment 2

[0032] In the pyrolysis reaction step 2 of this embodiment, 100 g of the non-metallic separator of the waste printed circuit board remaining in step 1 and 1 g of hexamethylenetetramine are added to the rotary furnace reactor, and the non-metallic separator of the waste printed circuit board is The mass ratio of the isolate to hexamethylenetetramine is 1:0.01, and other steps of this step are the same as in Example 1. Other steps are identical with embodiment 1.

Embodiment 3

[0034] In the pyrolysis reaction step 2 of this embodiment, 100 g of the non-metallic separator of the waste printed circuit board remaining in step 1 and 5 g of hexamethylenetetramine are added in the rotary furnace reactor, and the non-metallic separator of the waste printed circuit board is The mass ratio of the isolate to hexamethylenetetramine is 1:0.05, and other steps of this step are the same as in Example 1. Other steps are identical with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com