Electrode composite material for lithium ion capacitor, manufacturing method thereof and electrode manufacturing

A technology of composite materials and manufacturing methods, which is applied in the manufacture of hybrid capacitor electrodes and hybrid/electric double layer capacitors, etc., can solve the problems of difficult mixing of active materials, time-consuming preparation of composite materials, poor stability, etc., to achieve time-saving preparation, Cost saving and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

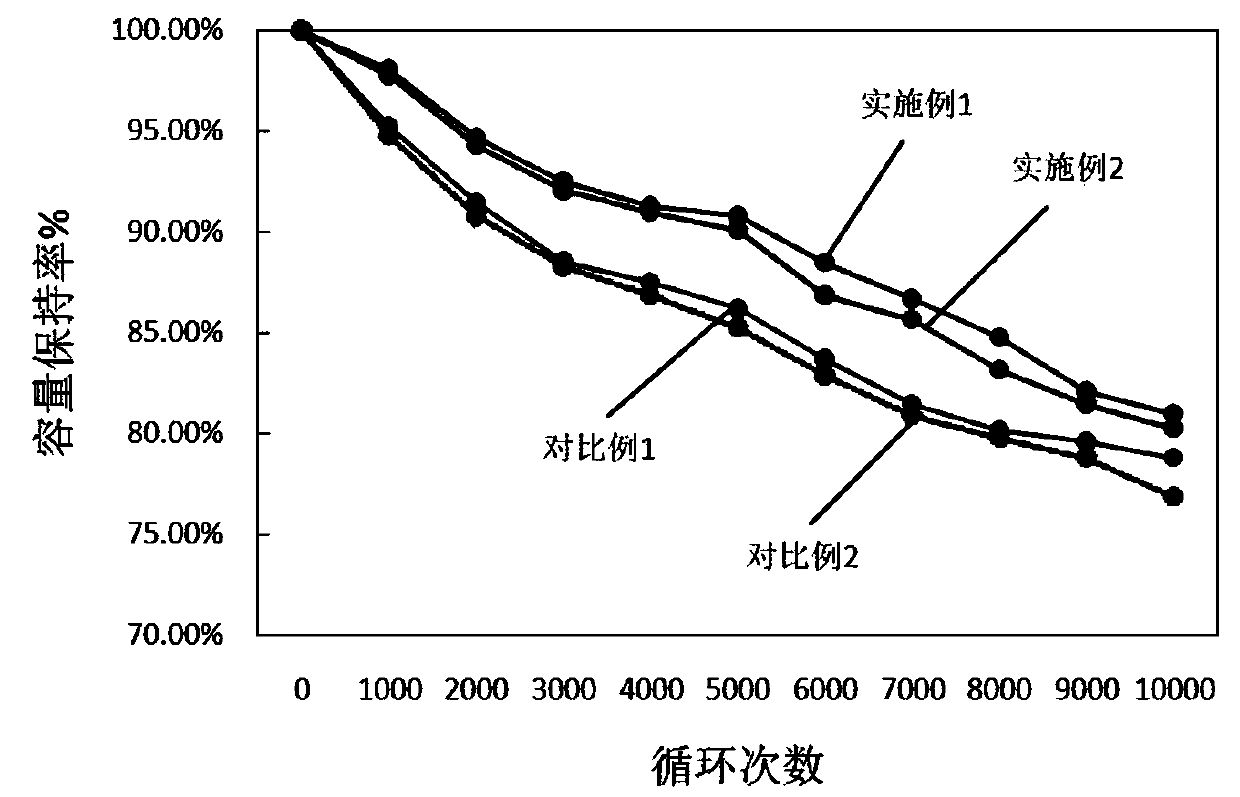

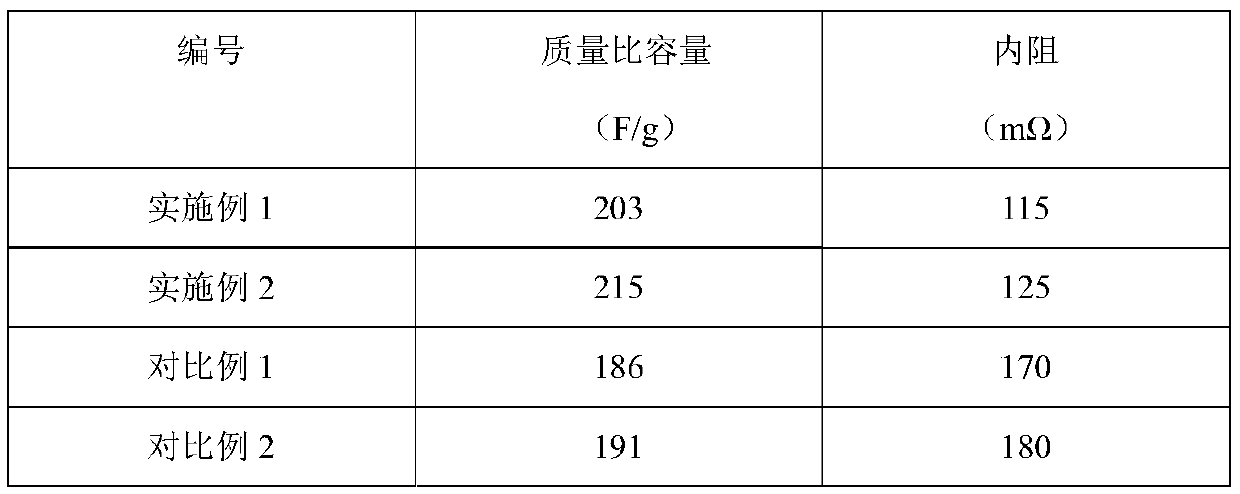

Examples

Embodiment 1

[0038] Pretreatment of Composite Materials

[0039] Weigh 2g activated carbon, 85g111 type ternary nickel cobalt manganese oxide lithium (NCM111) and 2g1,4bis(2-N',N'-dimethylethylamine)-5,8-dihydroxyanthraquinonepropanesulfonate Acid ylide (EAPS), put into the mixing cup, then pour 100g of absolute ethanol into the mixing cup with activated carbon and EAPS, seal the mixing cup with plastic wrap and stir at high speed until uniform. The mixture was heated by a one-time microwave for 45 minutes at a heat treatment temperature of 160°C.

[0040] Electrode preparation

[0041] Weigh 200g deionized water and 30g absolute ethanol, mix well, add 1.5g carboxymethylcellulose (CMC), pretreated active material, 8gketjen carbon black and 2.0gSBR type binder in turn, disperse evenly, and make electrode.

Embodiment 2

[0043] Pretreatment of Composite Materials

[0044] Weigh 8g of activated carbon, 75g of 523-type ternary nickel cobalt manganese oxide (NCM523) and 8g of 1,4 bis(2-N',N'-dimethylethylamine)-5,8-dihydroxyanthraquinone butanesulfonate Acid ylide (EADS), put into the mixing cup, then pour 110g of absolute ethanol into the mixing cup containing the active substance, seal the mixing cup with plastic wrap and stir at high speed until uniform. The mixture is subjected to a one-time 180°C high-temperature vacuum treatment for 60 minutes, with a vacuum degree of 10 -2 Pa.

[0045] Electrode preparation

[0046] Weigh 220g deionized water and 35g absolute ethanol, mix well, add 1.5g carboxymethyl cellulose (CMC), pretreated active material, 6gketjen carbon black and 2.0gSBR class binder successively, disperse evenly, make electrode.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com