Comprehensive treatment method for 1,4-dihydroxy anthraquinone production wastewater

A dihydroxyanthraquinone, comprehensive treatment technology, applied in natural water treatment, chemical instruments and methods, heating water/sewage treatment, etc. High problems, to achieve the effect of low cost, no solvent entrainment, and high partition coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

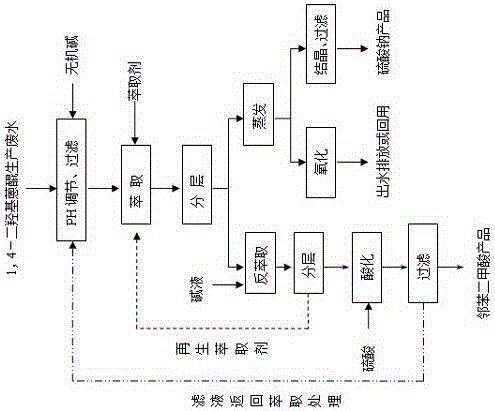

[0022] Embodiment 1, with reference to figure 1 , a comprehensive treatment method for 1,4-dihydroxyanthraquinone production wastewater, the steps are as follows:

[0023] (1) Extraction: Adjust the pH value of 1,4-dihydroxyanthraquinone production wastewater to 0.7 with an inorganic base and filter to remove mechanical impurities. Under normal temperature and pressure, fully mix with the extractant at a ratio of 1:1 to oil and water for 5 minutes. The raffinate phase after stratification is sent to the evaporation process after extraction, and the extraction phase is loaded with extractant and sent to the stripping process for regeneration;

[0024] (2) Stripping: take the above extraction phase and mix it with alkali solution at 40°C for 20 minutes under normal pressure. ; The regenerated extractant is recycled for the extraction process;

[0025] (3) Acidification: Stir the above stripping solution and add inorganic acid, adjust the pH value of the material to 0.7, filter...

Embodiment 2

[0027] Embodiment 2, with reference to figure 1 , a comprehensive treatment method for 1,4-dihydroxyanthraquinone production wastewater, the steps are as follows:

[0028] (1) Extraction: adjust the pH value of the 1,4-dihydroxyanthraquinone production wastewater to 1.5 with an inorganic base and filter to remove mechanical impurities. Under normal temperature and pressure, fully mix with the extractant at a ratio of 5:1 to oil and water for 3 minutes. The raffinate phase after stratification is sent to the evaporation process after extraction, and the extraction phase is loaded with extractant and sent to the stripping process for regeneration;

[0029] (2) Stripping: take the above extraction phase and mix it with alkali solution at 80°C for 10 minutes under normal pressure. ; The regenerated extractant is recycled for the extraction process;

[0030] (3) Acidification: Stir the above stripping liquid and add inorganic acid, adjust the pH value of the material to 1.5, filt...

Embodiment 3

[0032] Embodiment 3, with reference to figure 1 , a comprehensive treatment method for 1,4-dihydroxyanthraquinone production wastewater, the steps are as follows:

[0033] (1) Extraction: Adjust the pH value of 1,4-dihydroxyanthraquinone production wastewater to 1.20 with an inorganic base and filter it. Under normal temperature and pressure, it is fully mixed with the extraction agent at a ratio of 3:1 to oil and water for 4 minutes. The raffinate phase means that the water after extraction is sent to the evaporation process, and the extraction phase is the loaded extractant and sent to the stripping process for regeneration;

[0034] (2) Stripping: Take the above extraction phase and mix it with lye at 65°C for 15 minutes under normal pressure. The amount of alkali added for stripping is based on controlling the pH end point value at 9.0. After stratification, the stripping solution is sent to the acidification recovery system; The regenerated extractant is recycled for the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com