Biological filler embedded with anthraquinone and thiobacillus denitrificans, and sulfur autotrophic denitrification method

A technology of Thiobacillus denitrification and biological filler, which is applied in the direction of biochemical equipment and methods, chemical instruments and methods, biological treatment devices, etc., can solve the problems of low denitrification degradation efficiency and low mass transfer rate, and reduce waste water treatment. Cost, high water content, shortening the effect of hydraulic retention time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

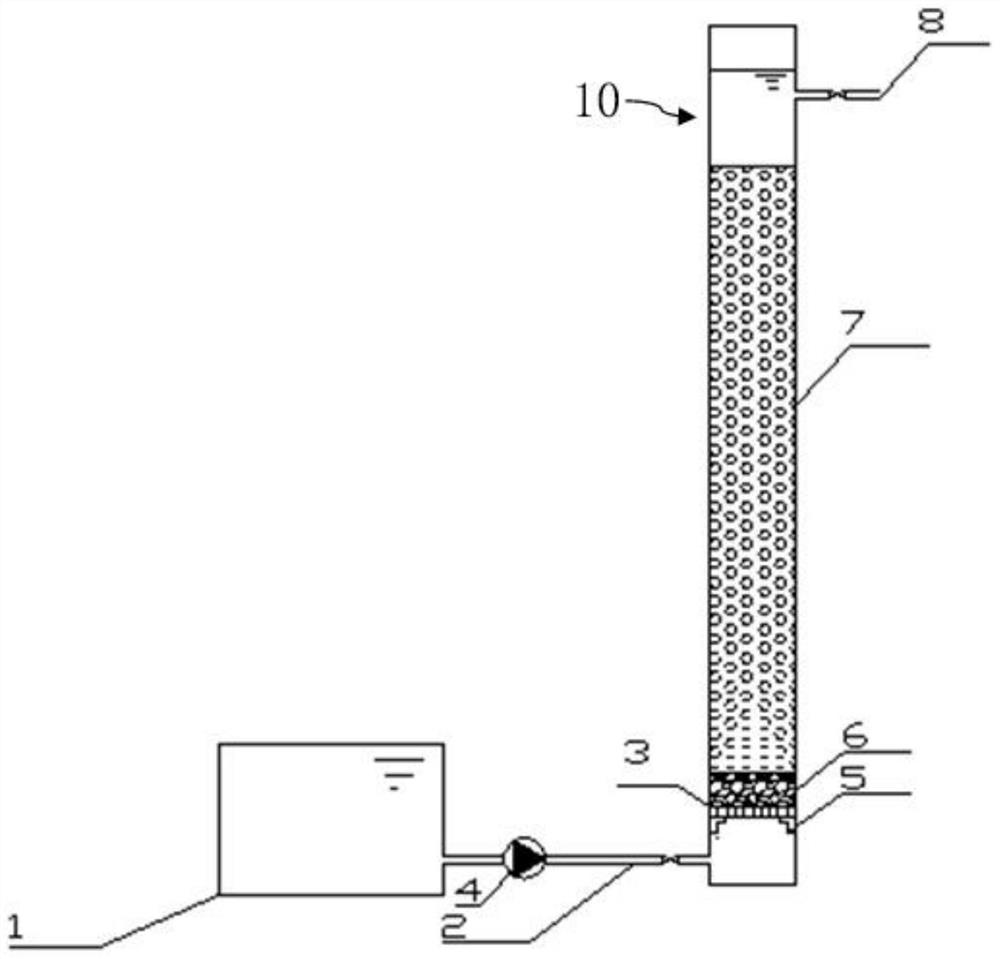

Method used

Image

Examples

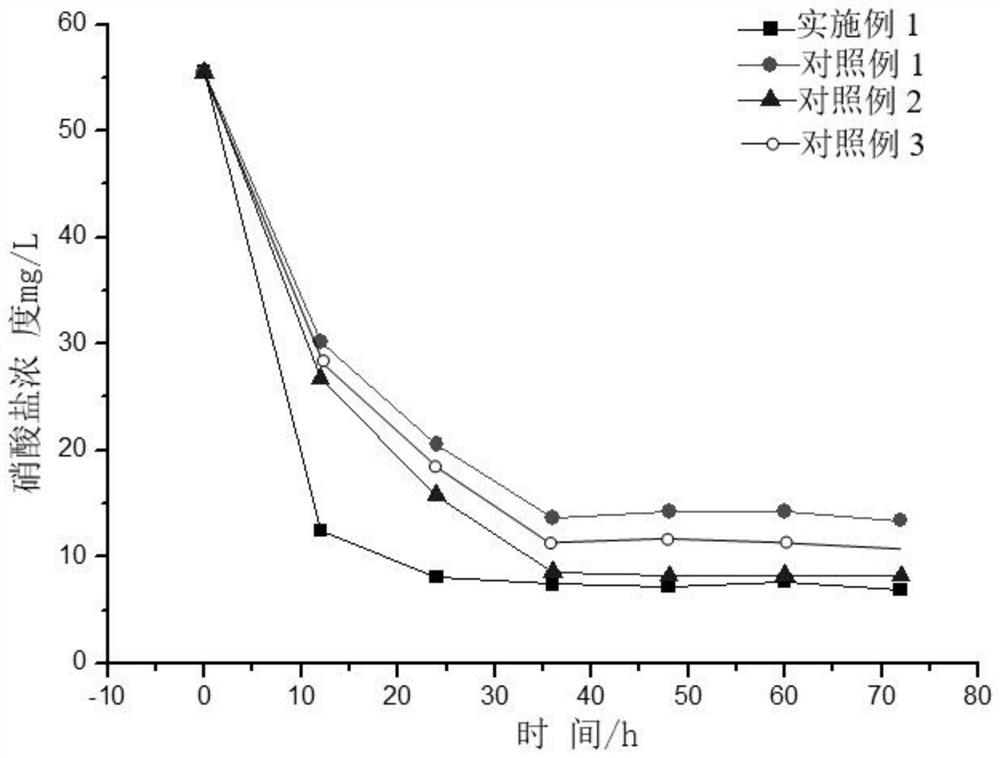

Embodiment 1

[0057] In this embodiment, the preparation method of biological filler is as follows:

[0058] (1) First, inoculate Thiobacillus denitrificans into the enriched liquid medium for 18 hours, and the culture temperature is 28°C. After the cultivation is completed, the wet cells of Thiobacillus denitrificans are obtained after centrifugation in a high-speed centrifuge. The speed of the high-speed centrifuge was 3000 r / min, and the centrifugation time was 8 min.

[0059] The preparation method of the enriched liquid culture medium is as follows: dissolving 5.0 g of sodium thiosulfate pentahydrate, 2.0 g of potassium nitrate, 1.0 g of sodium bicarbonate, 1.0 g of potassium dihydrogen phosphate and 0.5 g of magnesium chloride hexahydrate in 1000 mL of deionized water. The medium was adjusted to pH 7.0 with sodium hydroxide, and sterilized at 121°C for 30 min to obtain an enriched liquid medium. The initial inoculum concentration of the Thiobacillus denitrificans in the enriched liqu...

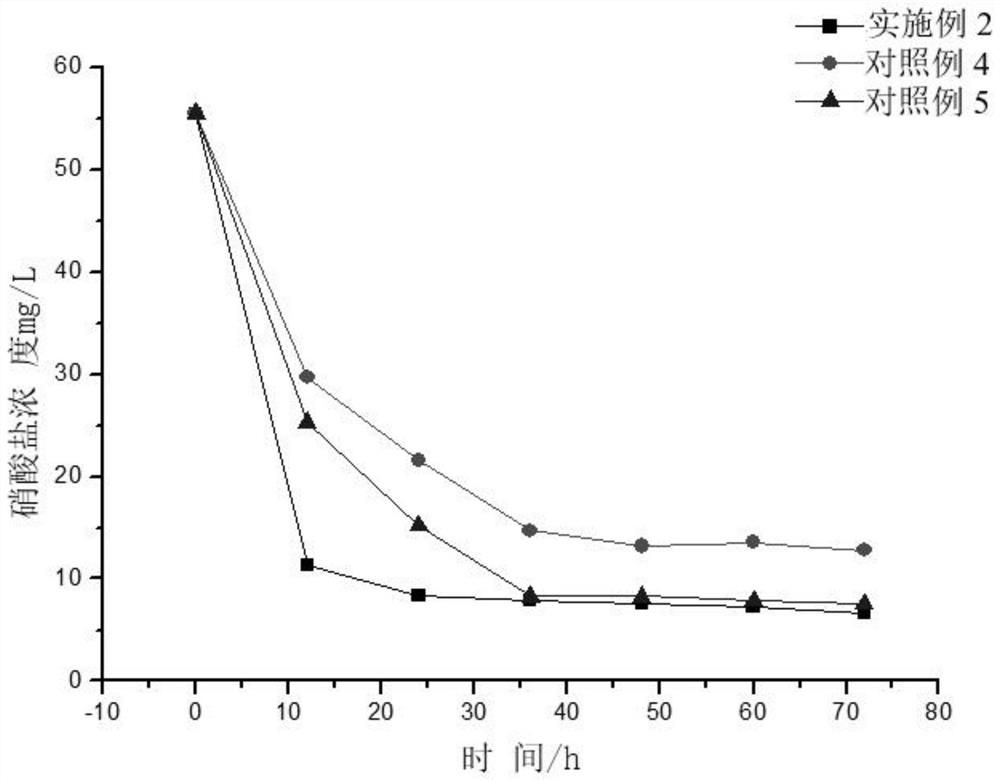

Embodiment 2

[0073] In this embodiment, the preparation method of biological filler is as follows:

[0074] (1) First, inoculate Thiobacillus denitrificans into the enriched liquid medium for 20 hours at a temperature of 31°C. After the cultivation is completed, centrifuge with a high-speed centrifuge to obtain wet cells of Thiobacillus denitrificans. The speed of the high-speed centrifuge was 3000 r / min, and the centrifugation time was 8 min.

[0075] (2) adding polyvinyl alcohol and sodium alginate to water, heating it in a 99°C water bath to make it into a viscous liquid, cooling to 25°C, and then sterilizing at high temperature to obtain an embedding agent precursor, wherein polyvinyl alcohol (w / w) of 8% and 2% (w / w) of sodium alginate.

[0076] (3) Wash the scallop shell with tap water, dry it in the air, dry it at 95°C, wash it with hydrochloric acid with a mass fraction of 4% for 2 minutes, and grind it to 50 mesh. Dry the ground scallop shell powder in an oven at 125°C. After co...

Embodiment 3

[0085] In this embodiment, the preparation method of biological filler is as follows:

[0086] (1) First, inoculate Thiobacillus denitrificans into the enriched liquid medium for 24 hours, and the culture temperature is 30°C. After the cultivation is completed, the wet cells of Thiobacillus denitrificans are obtained after centrifugation in a high-speed centrifuge. The speed of the high-speed centrifuge was 3000 r / min, and the centrifugation time was 8 min.

[0087] (2) adding polyvinyl alcohol and sodium alginate to water, heating it in a 99°C water bath to make it into a viscous liquid, cooling to 25°C, and then sterilizing at high temperature to obtain an embedding agent precursor, wherein polyvinyl alcohol (w / w) of 9% and 3% (w / w) of sodium alginate.

[0088] (3) Wash the scallop shell with tap water, dry it in the air, wash it with hydrochloric acid with a mass fraction of 4% for 2 minutes after drying at 95° C., and grind it to 60 mesh. Dry the ground scallop shell pow...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com