Key material of modified straw flocculant and technical method for same

A key material, modified straw technology, applied in the direction of flocculation/sedimentation water/sewage treatment, etc., can solve problems such as ineffective effects, achieve low operating costs, cost reduction, and simple production equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

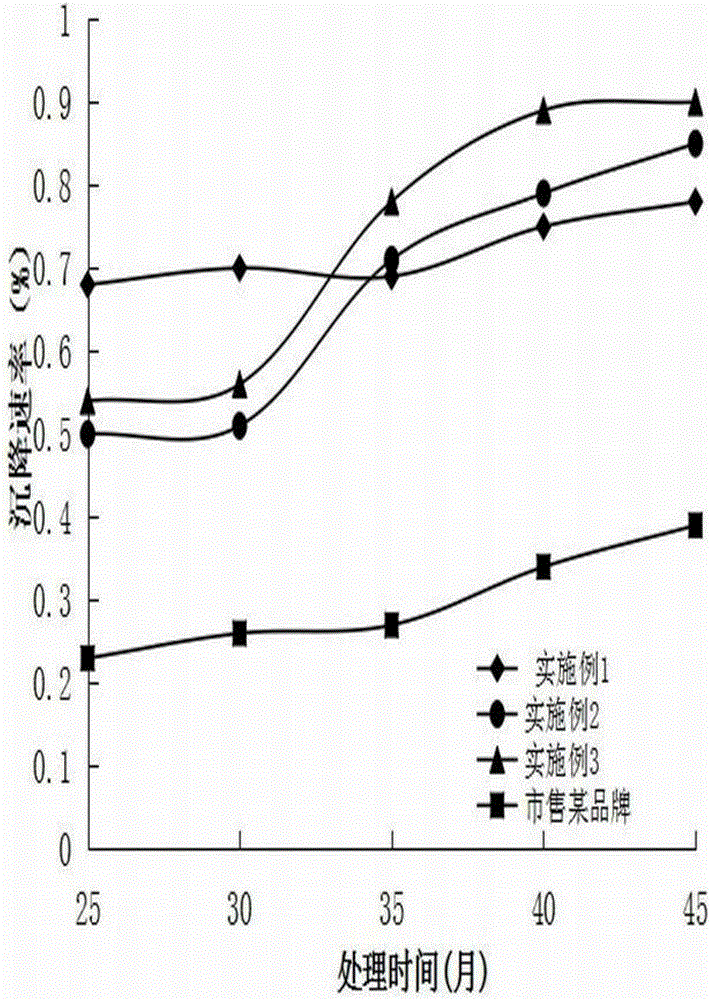

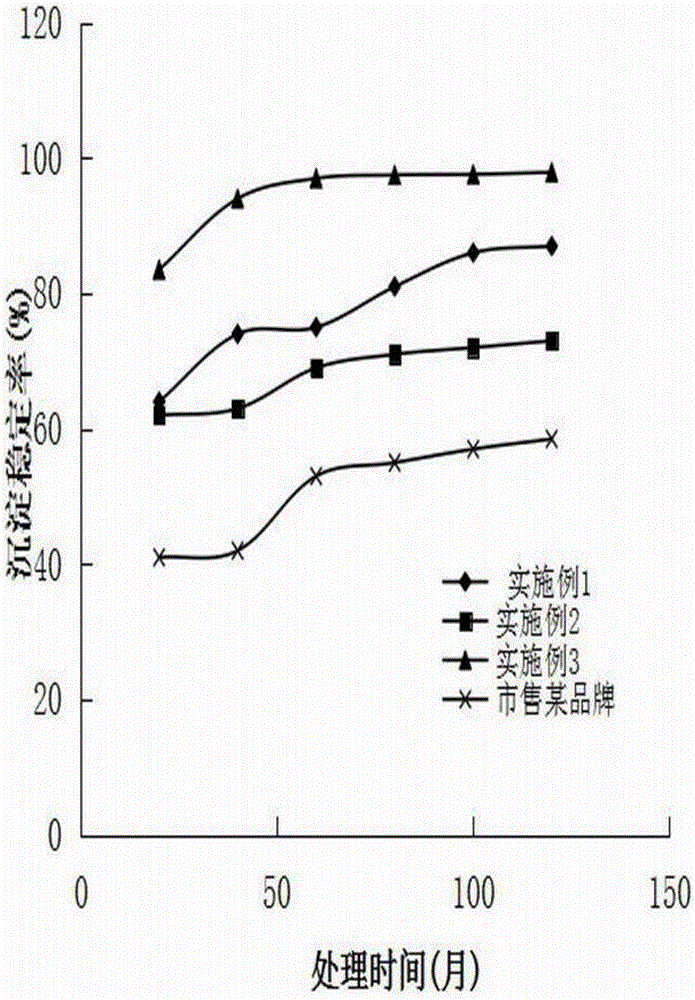

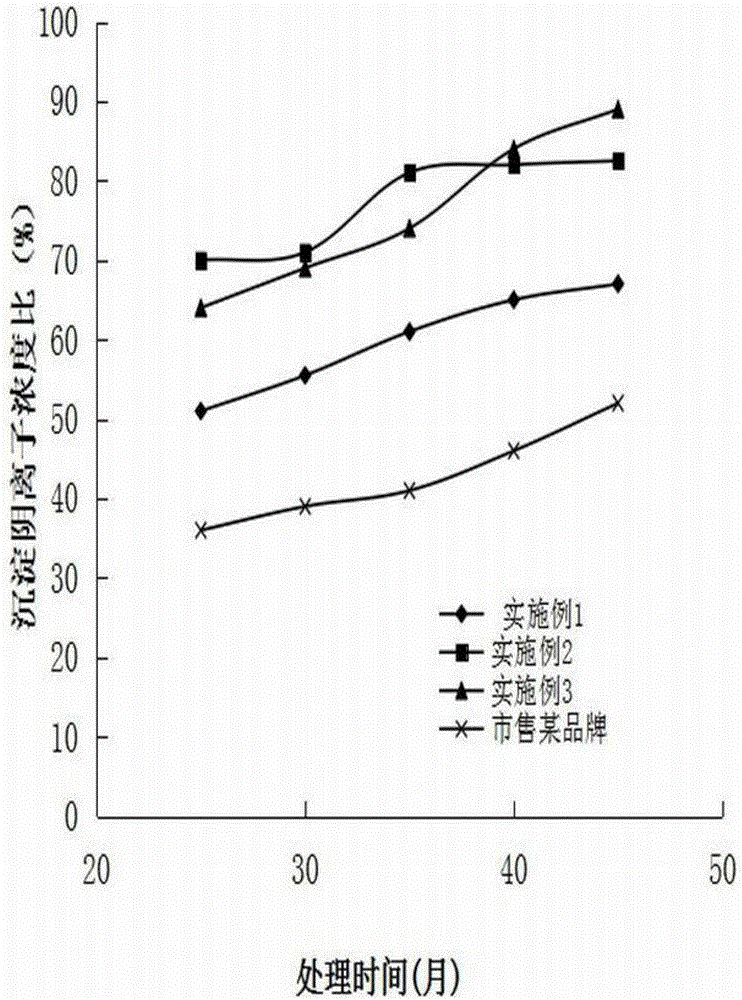

Examples

Embodiment 1

[0027] Prepare the key material of a modified straw flocculant according to the following steps in parts by weight:

[0028] Step 1: Add 238.833 parts of ozonated ultrapure water and 30.68 parts of straw powder into the continuous stirring reactor, start the mixer in the continuous stirring reactor, set the speed at 31.46rpm, and start the heating furnace in the continuous stirring reactor Blower to raise the temperature to 46.564°C, add 33.873 parts of phenylsuccinic acid and stir evenly, carry out deesterification reaction for 23.620 minutes, add 29.590 parts of nonylphenol sulfosuccinic acid monoester disodium salt, and the flow rate is 22.960m 3 / min of fluorine gas for 0.31 hours; then add 32.72 parts of N-(2-tolyl)trichloroacetamide to the continuous stirring reactor, and start the heating furnace blower in the continuous stirring reactor again to raise the temperature to 63.564°C. Keep warm for 23.960 minutes, add 35.15 parts of 1-amino-2-bromo-4-[(4-methylphenyl)amino]...

Embodiment 2

[0036] Prepare the key material of a modified straw flocculant according to the following steps in parts by weight:

[0037] Step 1: Add 463.67 parts of ozonized ultrapure water and 72.672 parts of straw powder to the continuous stirring reactor, start the mixer in the continuous stirring reactor, set the speed at 77.783 rpm, and start the heating furnace in the continuous stirring reactor Blower to raise the temperature to 47.569°C, add 142.556 parts of phenylsuccinic acid and stir evenly, carry out deesterification reaction for 34.53 minutes, add 46.21 parts of nonylphenol sulfosuccinic acid monoester disodium salt, and the flow rate is 63.787m 3 / min of fluorine gas for 0.96 hours; then add 89.872 parts of N-(2-tolyl)trichloroacetamide into the continuous stirring reactor, and start the heating furnace blower in the continuous stirring reactor again to raise the temperature to 96.569°C. Keep warm for 34.27 minutes, add 96.443 parts of 1-amino-2-bromo-4-[(4-methylphenyl)amin...

Embodiment 3

[0045] Prepare the key material of a modified straw flocculant according to the following steps in parts by weight:

[0046] Step 1: Add 238.9833 parts of ozonated ultrapure water and 30.968 parts of straw powder into the continuous stirring reactor, start the mixer in the continuous stirring reactor, set the speed at 31.946rpm, and start the heating furnace in the continuous stirring reactor Blower to raise the temperature to 46.9564°C, add 33.9873 parts of phenylsuccinic acid and stir evenly, carry out deesterification reaction for 23.9620 minutes, add 29.9590 parts of nonylphenol sulfosuccinic acid monoester disodium salt, and the flow rate is 22.9960m 3 / min of fluorine gas for 0.931 hours; then add 32.972 parts of N-(2-tolyl)trichloroacetamide into the continuous stirring reactor, and start the heating furnace blower in the continuous stirring reactor again to raise the temperature to 63.9564°C. Keep warm for 23.9960 minutes, add 35.915 parts of 1-amino-2-bromo-4-[(4-meth...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com