1-propylene oxygen basis-4-hydroxyanthraquinone-9, 10-diketone and method of preparing the same and application thereof

A technology of polytetrafluoroethylene board and reclaimed water, which is applied to the preparation of quinones, chemical instruments and methods, and the preparation of organic compounds, etc. It can solve the problems that are difficult to meet, the water content cannot be monitored in real time, continuous, on-line, and the time-consuming detection limit of water content And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

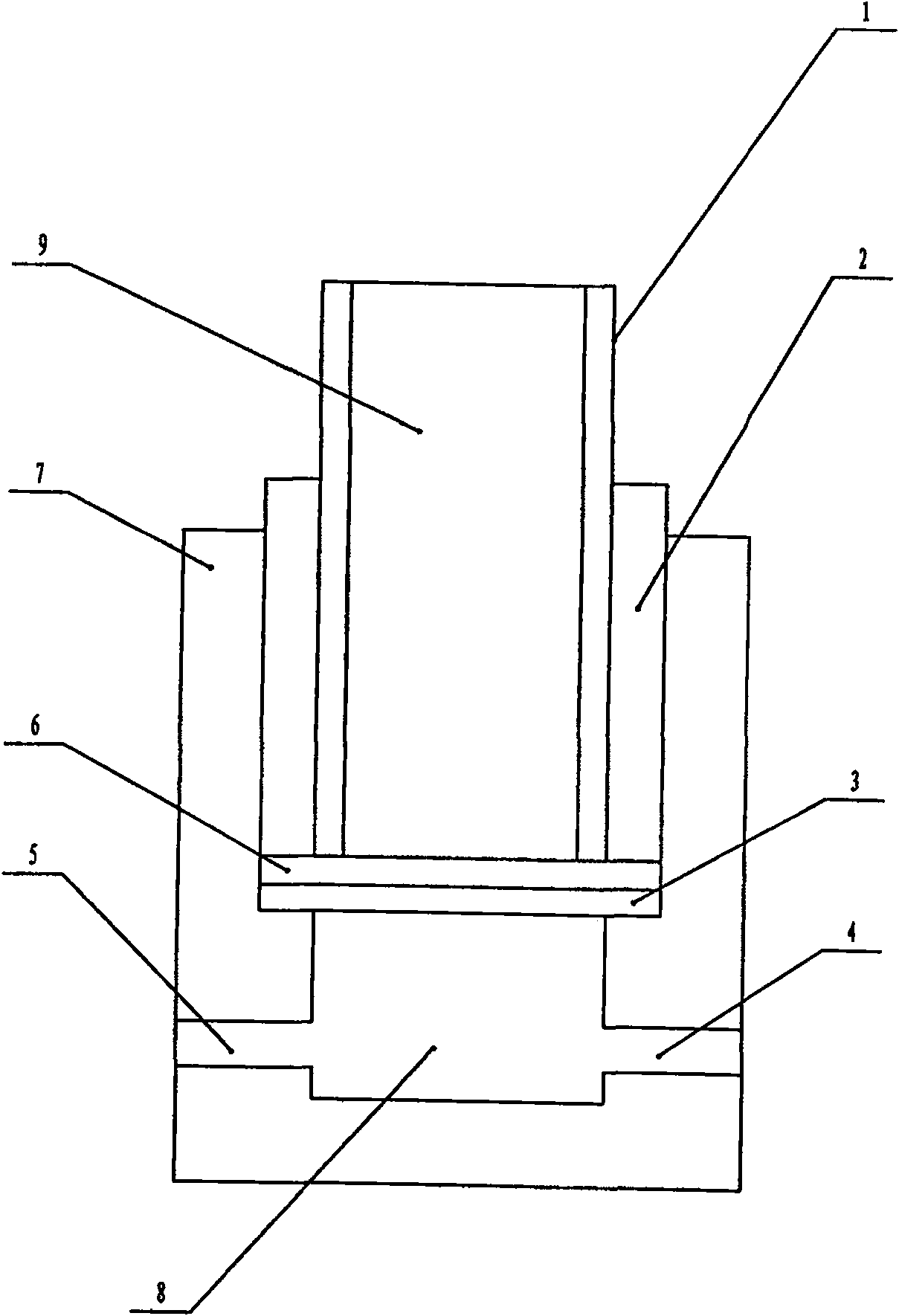

Image

Examples

Embodiment 1

[0024] Embodiment 1: A kind of 1-allyloxy-4-hydroxy anthraquinone-9,10-dione, its molecular structure and reaction are as follows,

[0025]

[0026] The synthesis steps are as follows,

[0027]Under magnetic stirring and nitrogen protection, 5.5 g of anhydrous potassium carbonate was added in batches to 9.6 g of 1,4-dihydroxyanthraquinone- 9, 10-diketone solution, after 15-30min, a thick muddy potassium salt is formed, then add 200ml of dried DMF solution, heat the mixture to 55-60°C for 30min, add 18ml of allyl bromide, and then heat the mixture to 65-70°C, react for 40 hours, cool to 5°C, acidify with 80ml of 1M hydrochloric acid, add 300ml of water, 300ml of dichloromethane and stir well, at this time the phases are separated, the aqueous layer is extracted three times with 300ml of dichloromethane, and the organic phases are combined for extraction , continuously wash with 400ml water, 400ml brine, add MgSO 4 Dried, filtered, evaporated solvent to obtain about 11g pro...

Embodiment 2

[0036] The synthetic steps of 1-allyloxy-4-hydroxyanthraquinone-9,10-dione are as follows,

[0037] The steps are: 5g of anhydrous potassium carbonate is added to 9g of 1,4-dihydroxyanthraquinone-9,10-dione solution dissolved in 150ml of dried N,N-dimethylformamide, and after 15min Slurry potassium salt, then add 150ml of dried DMF solution, heat the mixture to 55°C for 30min, add 15ml of allyl bromide, then heat the mixture to 65°C, react for 35h, cool to 5°C, acidify with hydrochloric acid, and Add water, stir the dichloromethane fully, at this time the phases are separated, the aqueous layer is extracted three times with dichloromethane, the combined organic phase is extracted, continuously washed with water and brine, and added MgSO 4 Dry, filter, and evaporate the solvent to obtain the product, which is purified by silica gel chromatography.

[0038] All the other are the same as embodiment 1

Embodiment 3

[0040] The synthetic steps of 1-allyloxy-4-hydroxyanthraquinone-9,10-dione are as follows,

[0041] The steps are: add 6g of anhydrous potassium carbonate to 10g of 1,4-dihydroxyanthraquinone-9,10-dione solution dissolved in 250ml of dried N,N-dimethylformamide, and form after 30min Slurry potassium salt, then add 250ml of dried DMF solution, heat the mixture to 60°C for 60min, add 25ml of allyl bromide, then heat the mixture to 70°C, react for 45h, cool to 5°C, acidify with hydrochloric acid, and Add water, stir the dichloromethane fully, at this time the phases are separated, the aqueous layer is extracted three times with dichloromethane, the combined organic phase is extracted, continuously washed with water and brine, and added MgSO 4 Dry, filter, and evaporate the solvent to obtain the product, which is purified by silica gel chromatography.

[0042] All the other are the same as embodiment 1

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com