Method for preparing laminated composite metal hydroxide

A hydroxide and layered composite technology, applied in the direction of oxide/hydroxide preparation, etc., can solve the problems of unclean preparation method, difficulty in industrialization, high cost of raw materials, etc., to protect the environment, overcome high cost, and save water resource effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

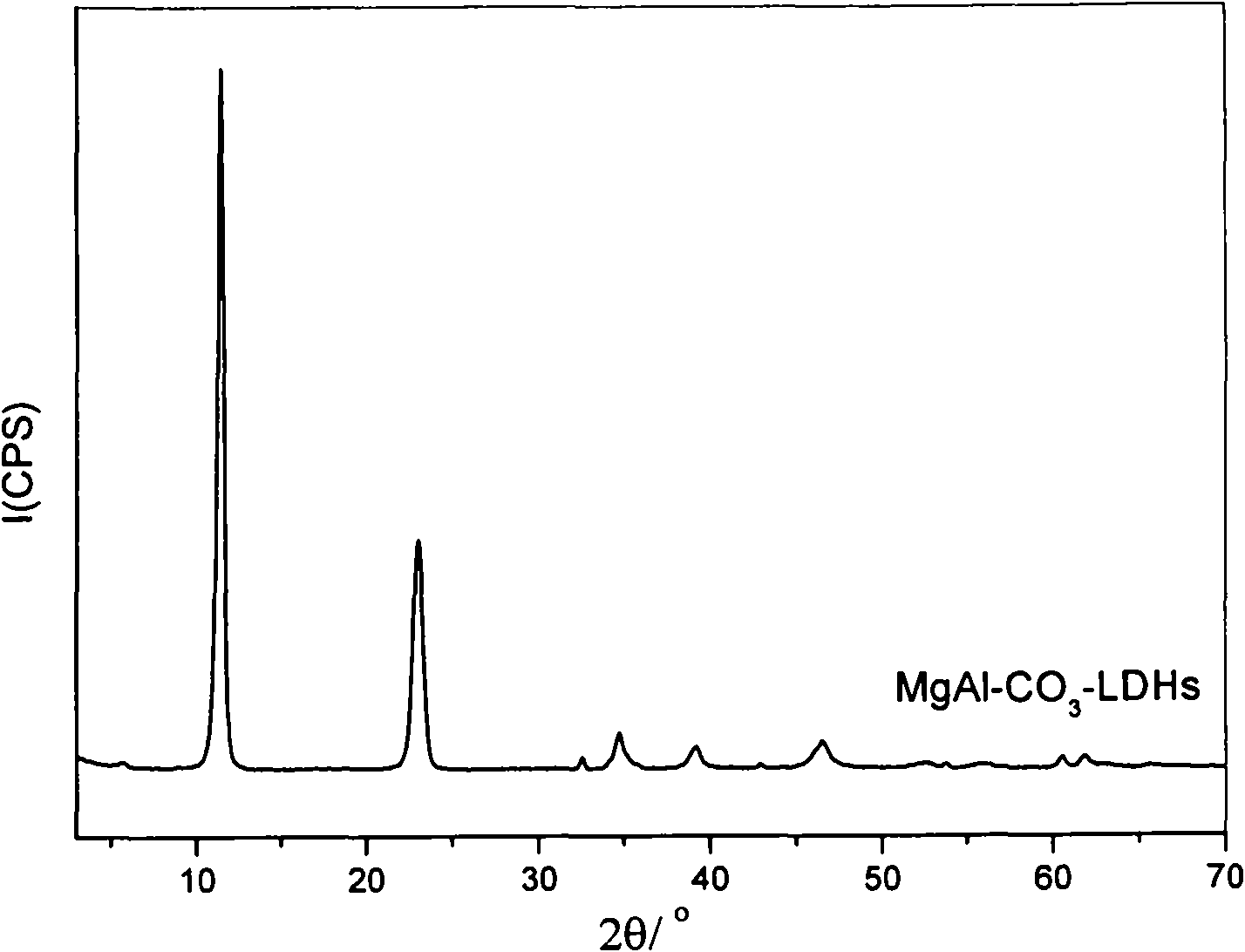

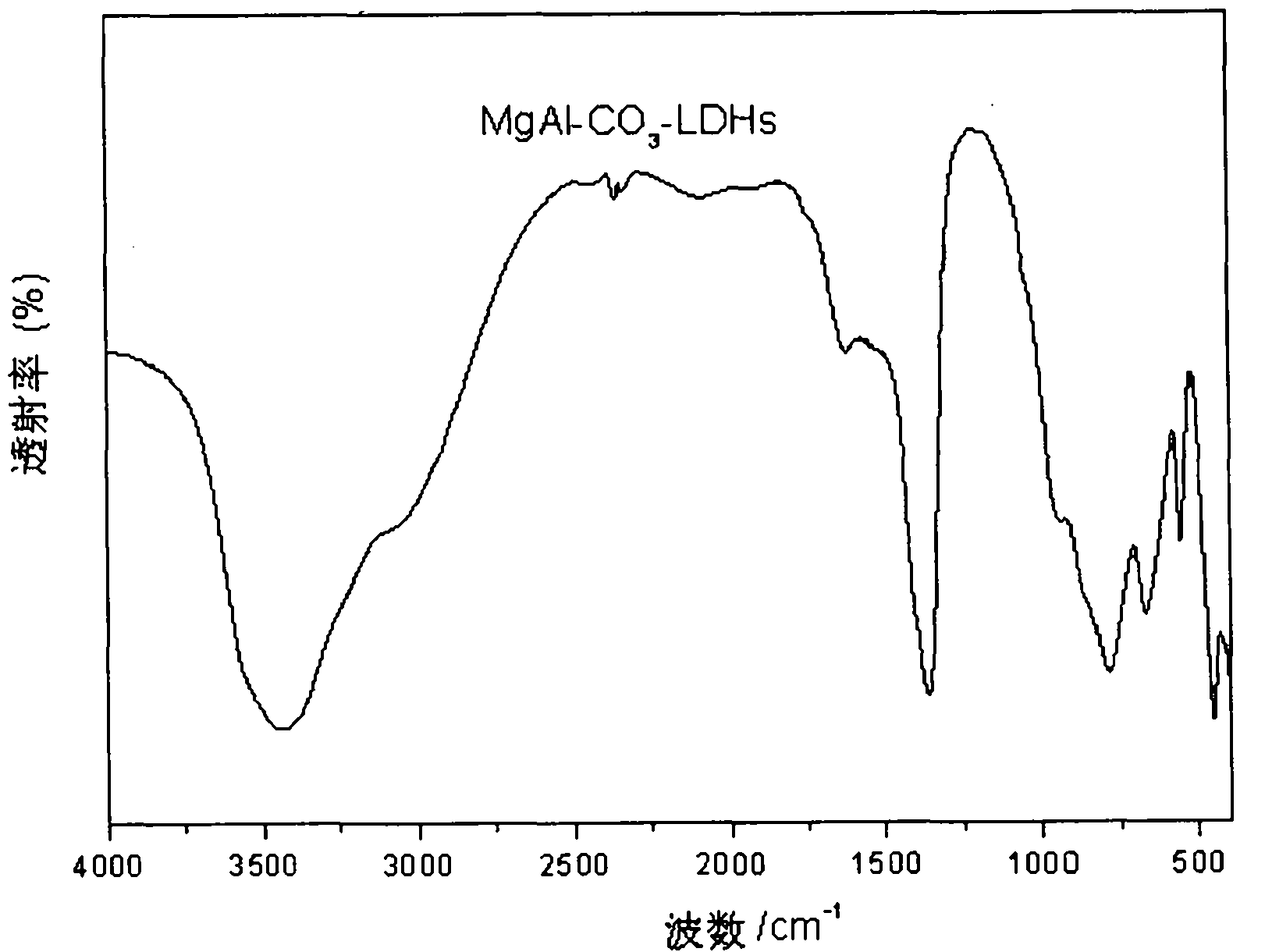

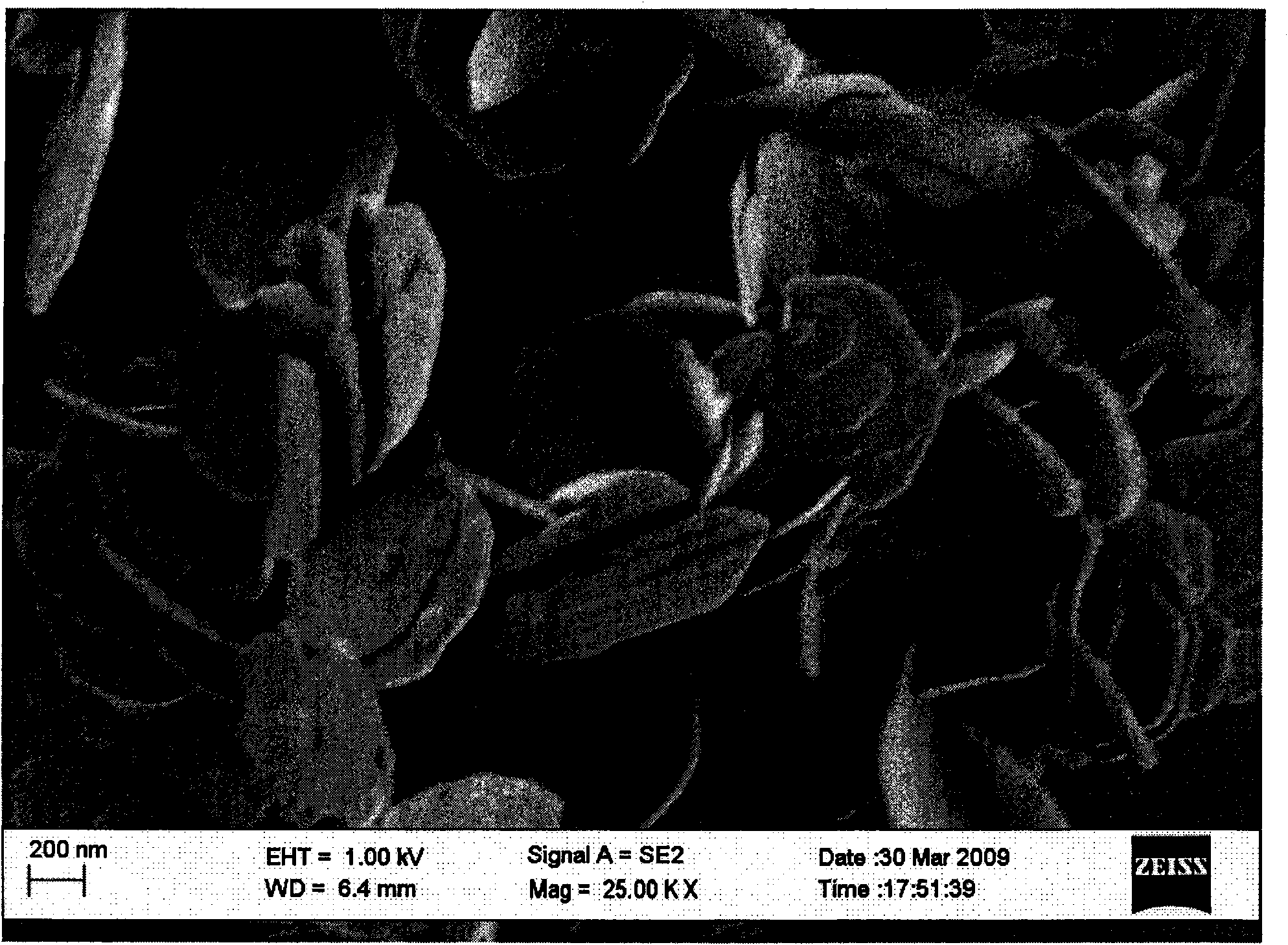

[0012] The preparation method of layered composite metal hydroxide provided by the invention comprises: M(OH) 2 and N(OH) 3 Mix at a molar ratio of 2-4:1, then react with an acidic aqueous solution at 100-300°C for 0.1-10 days under stirring conditions, and use M(OH) 2 and N(OH) 3 The total weight is 1 part by weight, and the consumption of the acidic aqueous solution is 1-1000 parts by weight; the acid and N(OH) in the acidic aqueous solution 3 The molar ratio of N is (n-1): 1 to (n+1): 1, n represents the number of hydrogen per molecule of acid, for example, for sulfuric acid H 2 SO 4 and carbonic acid H 2 CO 3 , the number of hydrogen in each molecule of acid is 2, that is, sulfuric acid H 2 SO 4 and carbonic acid H 2 CO 3 The n is 2. The M(OH) 2 For brucite or brucite and Zn(OH) 2 , Ca(OH) 2 、Cu(OH) 2 , Ni(OH) 2 、Co(OH) 2 , Fe(OH) 2 , Mn(OH) 2 , Cd(OH) 2 and Be(OH) 2 One or a mixture of several of them; N(OH) 3 For pseudo-boehmite or pseudo-boehmite an...

Embodiment 1

[0026] This example is used to illustrate the preparation method of the layered composite metal hydroxide provided by the present invention.

[0027] (1) Treatment of brucite

[0028] The main component of the brucite (Dandong Tianci Flame Retardant Material Technology Co., Ltd.) used is: Mg(OH) 2 96.47% by weight, CaO 0.45% by weight, Fe 2 o 3 0.48% by weight, Al 2 o 3 0.14% by weight, SiO 2 2.26% by weight.

[0029] The above-mentioned brucite of 5000 meshes and deionized water are mixed in a ratio of 20: 100 by weight, and pulverized for 30 minutes at a speed of 3000 rpm with a colloid mill (Shenyang Aerospace Xinguang Superfine Grinding Machinery Co., Ltd., JTM51AB type), and then All the obtained products were added to the reaction kettle. Under the condition of stirring, the temperature in the kettle was raised to 350°C, and the reaction was carried out under the pressure of 17MPa for 32 hours, and the obtained product was filtered and dried at 70°C for 8 hour...

Embodiment 2

[0035] This example is used to illustrate the preparation method of the layered composite metal hydroxide provided by the present invention.

[0036] (1) Treatment of brucite

[0037] The main component of the brucite (Dandong Tianci Flame Retardant Material Technology Co., Ltd.) used is: Mg(OH) 2 96.47% by weight, CaO 0.45% by weight, Fe 2 o 3 0.48% by weight, Al 2 o 3 0.14% by weight, SiO 2 2.26% by weight.

[0038] The above-mentioned brucite of 500 meshes and deionized water are mixed in a ratio of 30: 100 by weight, pulverized for 10 minutes at a speed of 8000 rpm with a colloid mill (Shenyang Aerospace Xinguang Superfine Grinding Machinery Co., Ltd., JTM51AB type), and then All the obtained products were added to the reaction kettle. The temperature in the kettle was raised to 300° C. with stirring, and the reaction was carried out under a pressure of 8.7 MPa for 6 hours, and the obtained product was filtered and dried at 90° C. for 6 hours.

[0039] (2) Prep...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com