Nano fiber coated linear composite material and its preparing method

A technology of nanofibers and composite materials, applied in the field of materials, can solve the problems of inability to be used in actual production, insufficient strength of nanofibers, and low output.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

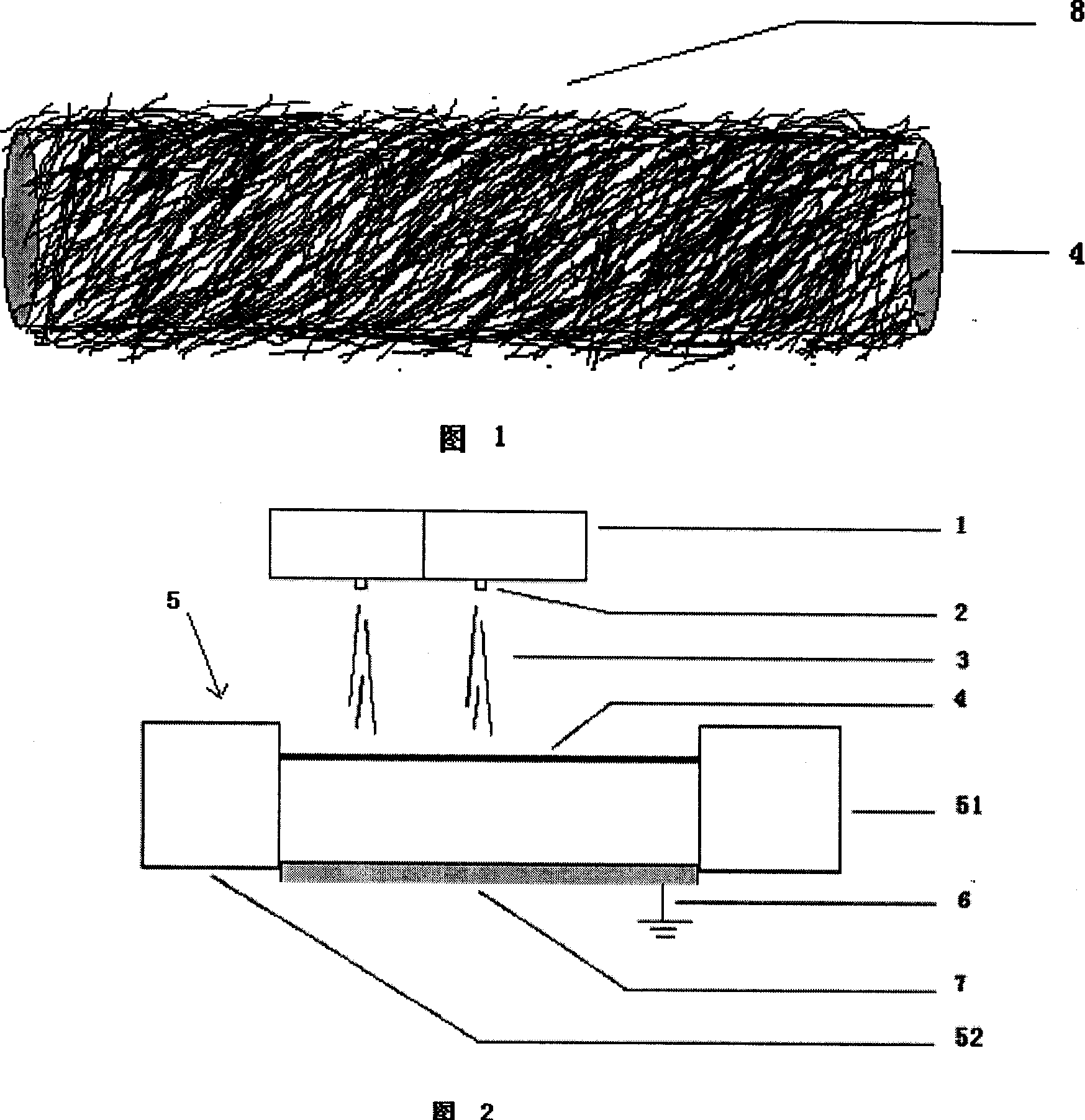

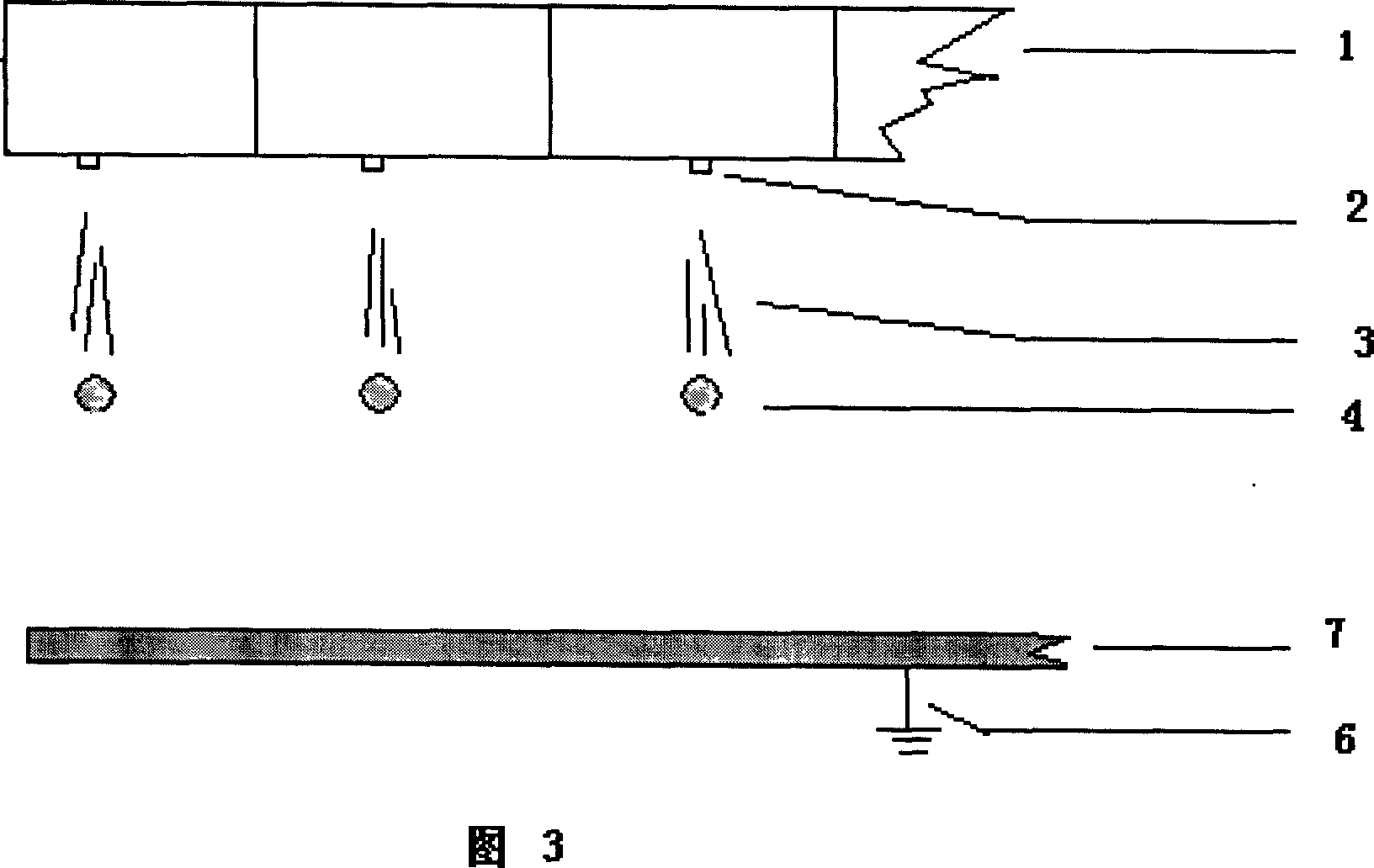

[0025] Common 100-denier polyester yarns are used as the linear base material 4, and under the action of the coating transmission mechanism 5 composed of the input device 52 and the output device 51, the common 100-denier polyester yarns are input by the input device 52 at a speed of 1 m / s. The speed is continuously input and output by the output device 51 at an output speed of 1 m / s. During the conveying process, the two ends of the ordinary 100-denier polyester yarn continue to rotate clockwise along its own axis at a rotation speed of 10 rpm. The carbon nanotube viscose nanofiber 3 formed by spraying out the carbon nanotube viscose nanofiber 3 formed by the 5% carbon nanotube and the 95% viscose blend in the electrospinning box 1 through the spinning port 2 is directed toward the Ordinary 100-denier polyester filaments fall, and are wound and coated on ordinary 100-denier polyester filaments with the rotation of ordinary 100-denier polyester filaments. The polyester solution...

Embodiment 2

[0028] Using ordinary 80-count cotton yarn as the linear substrate 4, under the action of the covering transmission mechanism 5 composed of the input device 52 and the output device 51, the ordinary 80-count cotton yarn is continuously Input and output by the output device 51 at an output speed of 500 m / s. During the conveying process, the input end of the ordinary 80-count cotton yarn continues to rotate clockwise along its own axis at a rotation speed of 3000 rpm, and the output end continues to rotate clockwise at a speed of 5000 m / s. The rotation speed of revolution / second rotates clockwise along its own axis, and the nano-silver particles with a mass percentage of 2% and the polylactic acid blend solution with a mass percentage of 98% in the electrospinning box 1 are sprayed out through the spinning port 2 to form The nano-silver polylactic acid nanofiber 3 falls to the ordinary 80-count cotton yarn under the action of an electric field, and is wound and coated on the ordi...

Embodiment 3

[0031] Using flax fiber as the linear substrate 4, under the action of the coating transmission mechanism 5 formed by the input device 52 and the output device 51, the flax fiber is continuously input by the input device 52 at an input speed of 1000 m / s, and is sent to the output device 51 is output at an output speed of 1000 m / s, and continuously rotates counterclockwise along its own axis at a rotation speed of 7000 r / s during the conveying process, and the polyacrylonitrile spinning in the first and second electrospinning boxes 1 The polyacrylonitrile nanofiber 3 formed by the liquid spraying out through the spinning port 2 falls to the flax fiber under the action of the electric field, and is wound and coated on the flax fiber with the rotation of the flax fiber. Continuously transported and rotated under the action of the transmission mechanism 5, the polyacrylonitrile nanofiber 3 continuously covers the flax fiber to form a continuous polyacrylonitrile nanofiber-coated li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com