Ceramic reinforced steel composite material and preparation method

A technology of composite materials and ceramics, applied in heat exchange equipment, rotors, cylinders, etc., can solve problems such as limited operating temperature, poor plasticity, and insufficient strength, and achieve low production costs, optimized mechanical properties, and simple production processes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Step 1: Make a sand casting model, and place Silicon carbide ceramic rods are used as reinforcements and fixed in the above-mentioned sand casting model; the matrix raw materials C, Mn, Si, Al and Fe are prepared for twinning induced plasticity steel and smelted into twinning induced plasticity steel, and the components in the twinning induction plasticity steel The mass proportion is: 0.4%C, 20.5%Mn, 0.80%Si, 0.05Al%, and the rest is Fe.

[0029] Step 2: pouring the liquid twinning induced plasticity steel smelted in step 1 into the casting mold;

[0030] Step 3: Static solidification and cooling. That is made to Silicon carbide ceramic rods as reinforcements for twin-induced plasticity steel matrix composites.

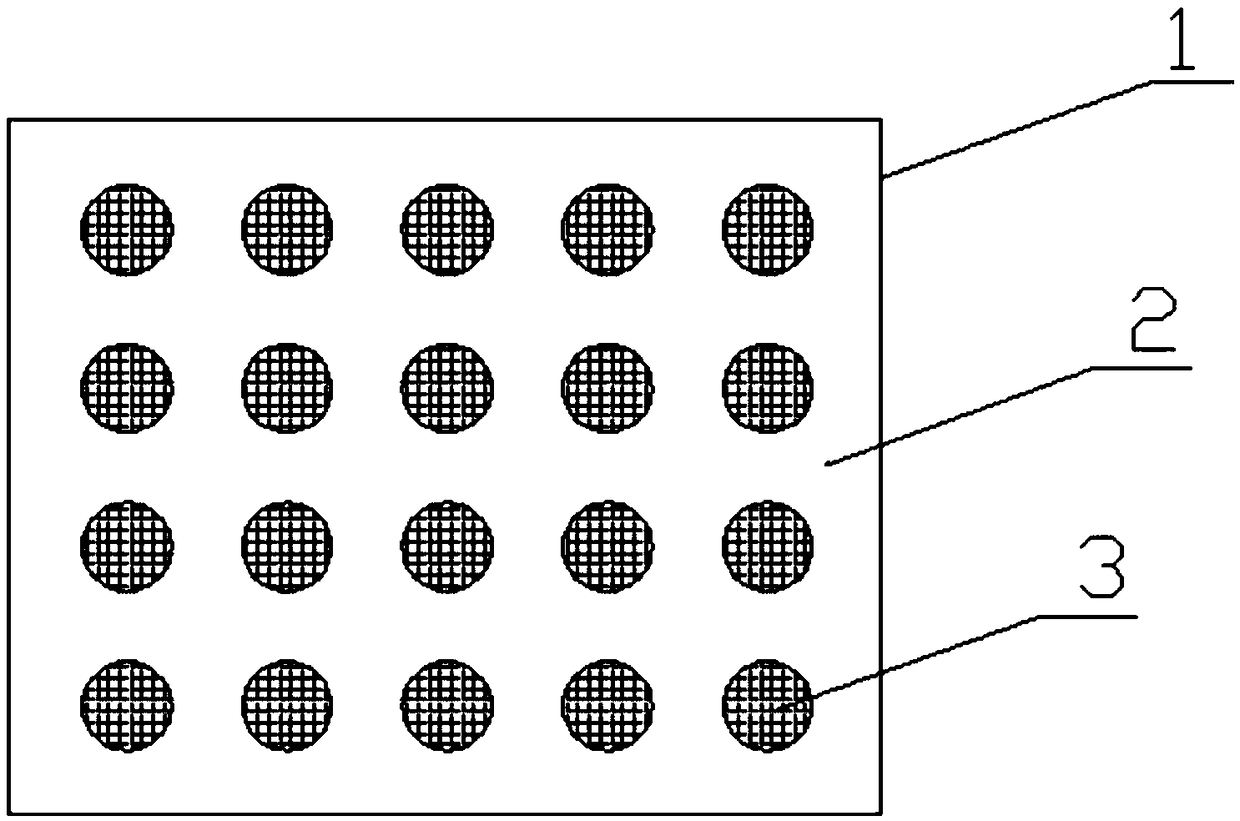

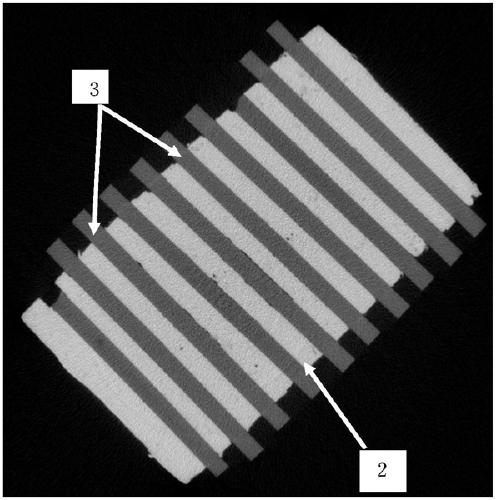

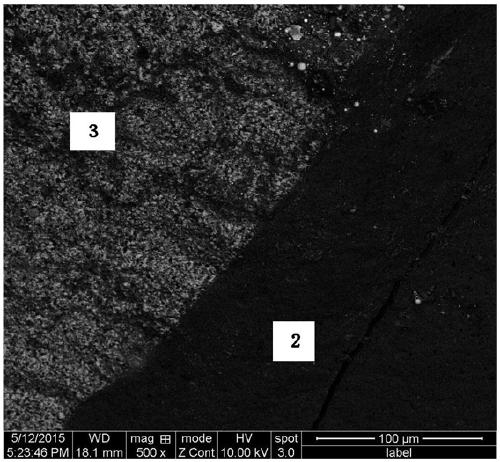

[0031] The cross-sectional structure of the ceramic-reinforced twin-induced plasticity steel matrix composite prepared in this example is as follows: figure 1 As shown, the twinning induced plasticity steel matrix 2 and the ceramic reinforcement 3 are co...

Embodiment 2

[0035] Adopt the same steps as Example 1 to make the ceramic reinforced steel composite material, the difference is:

[0036] 1. Use the casting model as the metal type, and the ceramic reinforcement as the zirconia ceramic rods.

[0037] 2. The mass proportion of each component in the twinning induced plasticity steel matrix is: 0.4%C, 5%Mn, 0.05%Si, 0.05Al%, and the rest is Fe.

[0038] The same method as in Example 1 was used to test, and it was measured that the as-cast bending strength of the prepared ceramic reinforced steel composite material reached 780 MPa.

Embodiment 3

[0040] Adopt the same steps as Example 1 to make the ceramic reinforced steel composite material, the difference is:

[0041] 1. Use the casting model as the disappearing type, and the ceramic reinforcement as silicon nitride ceramic rods.

[0042] 2. The mass proportion of each component in the twinning induced plasticity steel matrix is: 2.0%C, 35.0%Mn, 0.80%Si, 1.0Al%, and the rest is Fe.

[0043] The same method as in Example 1 was used to test, and it was measured that the as-cast bending strength of the prepared ceramic reinforced steel composite material reached 855 MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bending strength | aaaaa | aaaaa |

| Bending strength | aaaaa | aaaaa |

| Bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com