Automobile decorative part and manufacturing process thereof

A technology for car decoration and trim, which is applied to household components, other household appliances, household appliances, etc., can solve the problems of weak bonding strength, large inner diameter error, easy dislocation, etc., and achieves enhanced pull-out strength, torsion resistance characteristics, spacing The distance error is small and the effect of overcoming the lack of strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

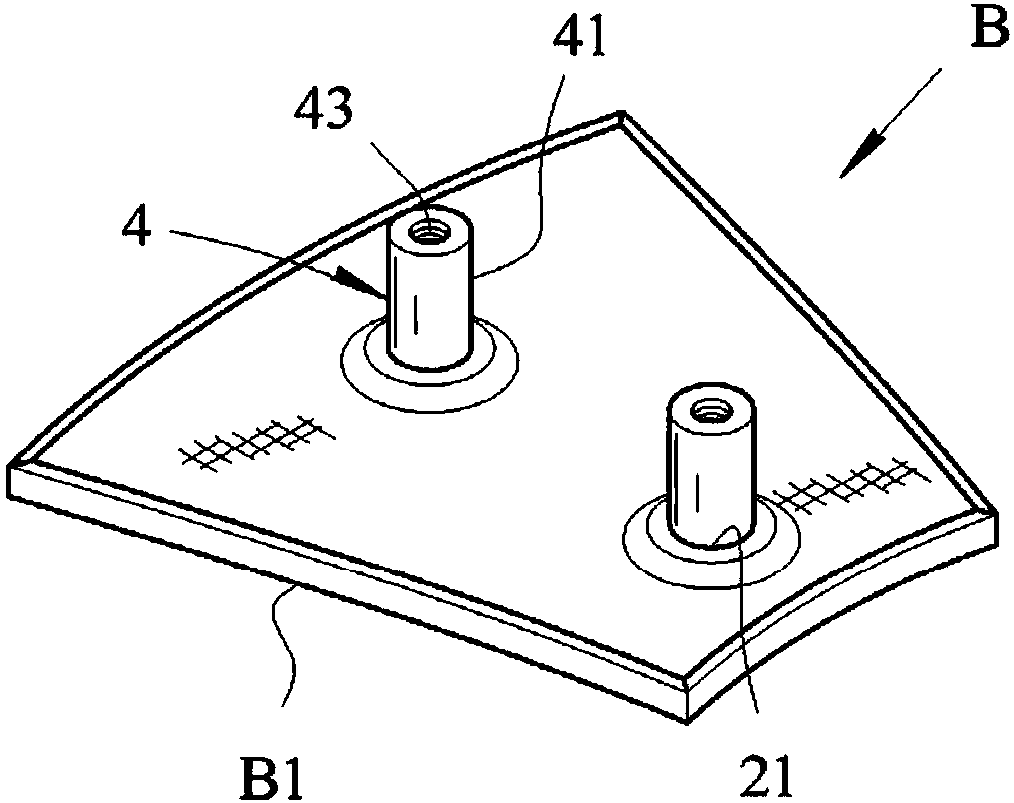

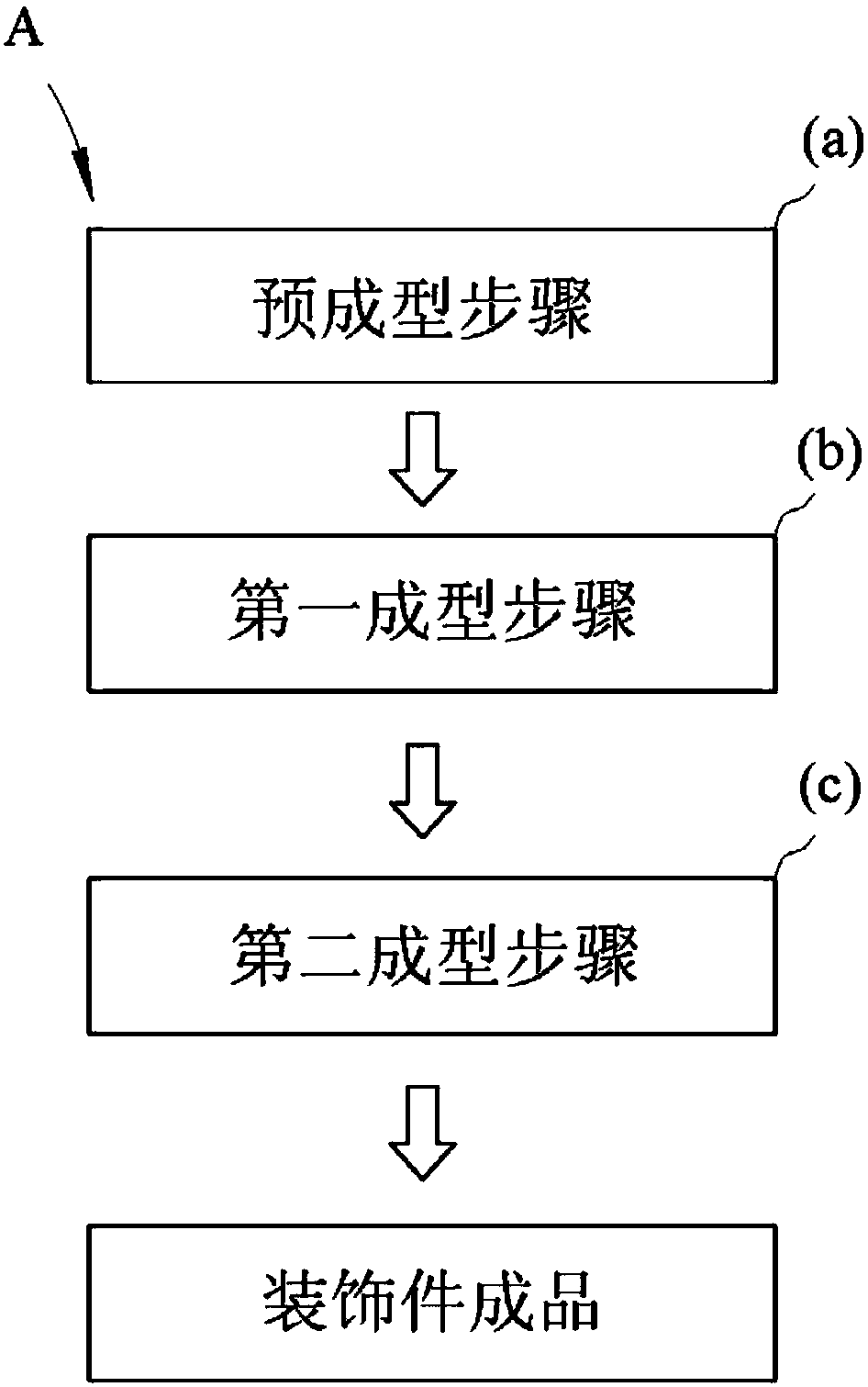

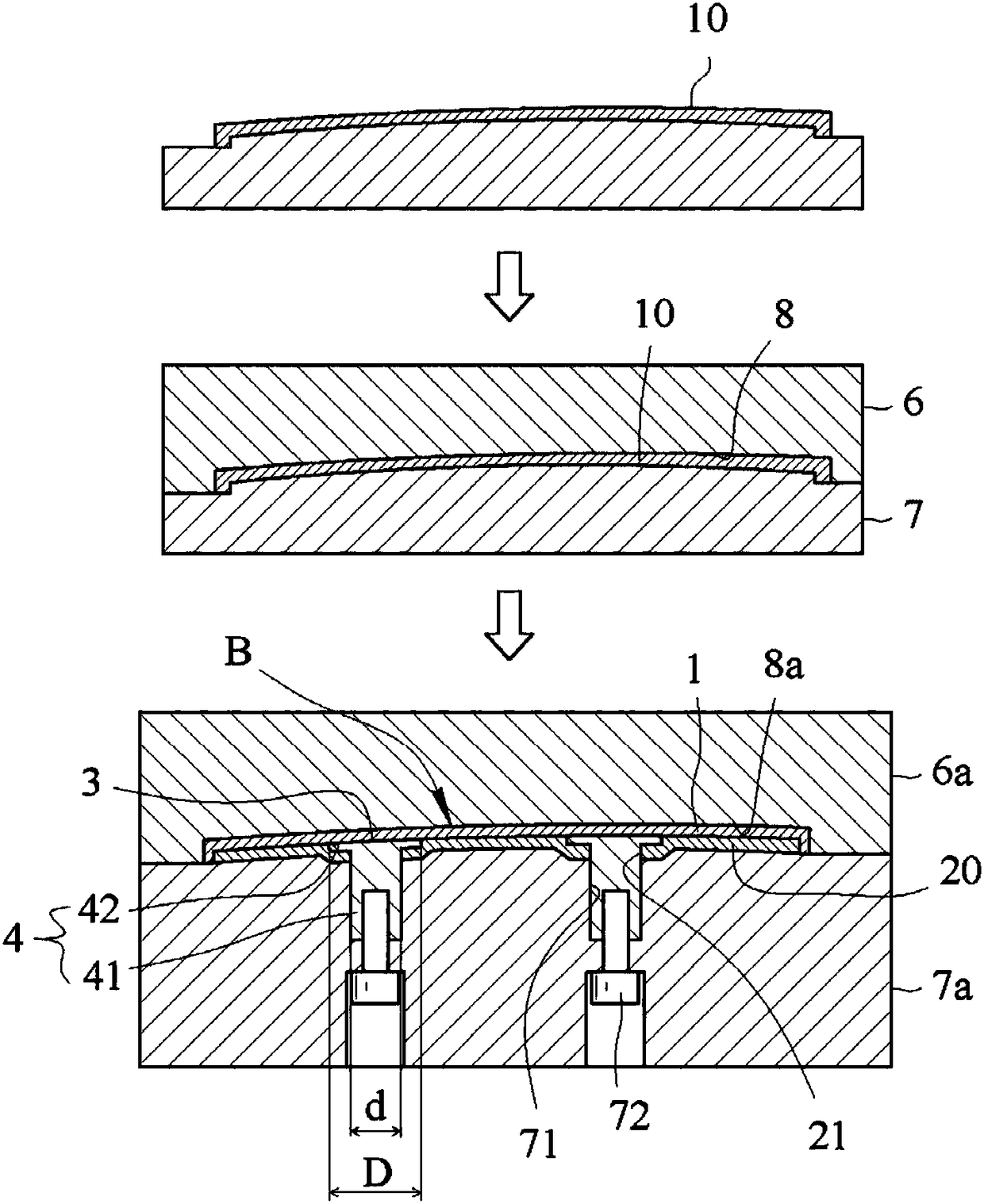

[0060] See first Figure 1 to Figure 3 As shown, it is a kind of automotive trim manufacturing process A of the present invention, which includes: a preforming step (a), first cutting the soft composite material cloth (or carbon fiber cloth) into at least one outer layer of the desired shape Cloth 10 and an inner layer cloth 20, and the inner layer cloth 20 must have at least one perforation 21, and the inner diameter d of the perforation 21 is smaller than the outer diameter D of the flange portion 42 of the binding member 4; a first forming step ( b), the outer layer cloth 10 is placed in the upper mold 6 and the lower mold 7 for molding, that is, after being pressurized and heated, it is placed in the mold and the composite material cloth or carbon fiber cloth is solidified and demolded to obtain a hardened outer layer 1 , and the hardened outer layer 1 can be made by impregnating or injecting glue; a second molding step (c) is to place the hardened outer layer 1, the inner...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com