Method for preparing modified liquid metal soap thermal stabilizer through potassium ion characteristic doping

A liquid metal and heat stabilizer technology, applied in the preparation of carboxylate, can solve the problems of poor stability and compatibility, complex production process, deep color and so on, and achieve the effect of high thermal stability, process safety and high quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

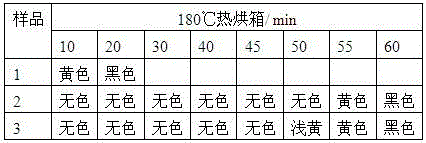

Embodiment 1

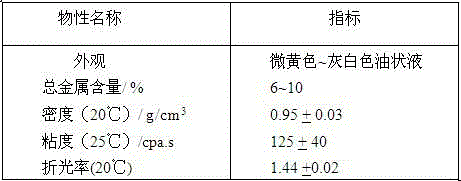

[0022] Add 43.2g of isooctanoic acid and 26.8g of p-tert-butylbenzoic acid successively into a 250mL three-necked flask, heat up to 90°C under constant stirring, control the reaction temperature at 90°C, add 14.0g of solid potassium hydroxide in batches until the reaction is complete, The solution became clear, and the water was distilled under reduced pressure; 32.6g of zinc oxide powder was added in batches, and the temperature was controlled at 80°C to react for 1 hour. A yellowish transparent oily liquid was obtained, which was sealed and stored.

Embodiment 2

[0024] Add 28.8g of isooctanoic acid and 17.0g of p-tert-butylbenzoic acid in sequence in a 250mL three-necked flask, heat up to 100°C under constant stirring, control the reaction temperature at 100°C, add 16.6g of potassium hydroxide in batches, and react for 2 hours under temperature control. After the reaction is complete, carry out vacuum distillation and dehydration; stop the distillation after the anhydrous comes out and lower the temperature to 80°C, add 28.5g of liquid Ca / Zn composite heat stabilizer and 30g of triethylene glycol, continue to control the temperature and stir for 10 minutes, and then carry out decompression Suction filtration to obtain a light yellow transparent oily liquid, which is sealed and stored.

Embodiment 3

[0026] Add 14.2g of isooctanoic acid and 17.5g of p-tert-butylbenzoic acid in sequence in a 250mL three-necked flask, heat up to 90°C under constant stirring, control the reaction temperature at 90°C, add 11.0g of potassium hydroxide in batches, and react for 2 hours under temperature control. After the reaction is complete, carry out vacuum distillation and dehydration; stop the distillation after the anhydrous comes out and lower the temperature to 80°C, add 25.0g of liquid Mg / Zn composite heat stabilizer and 24g of odorless kerosene, continue to control the temperature and stir for 10min, then carry out vacuum pumping Filter to obtain a golden yellow transparent oily liquid, which is sealed and stored.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com