Rare earth complex, preparation method and applications thereof

A technology of rare earth complexes and rare earth elements, applied in the field of National Natural Science Foundation of China project funding results, rare earth complexes and their preparation, can solve the problems of poor PVC stability, poisonous lead salt stabilizers, lack of lubricity, etc. , achieve excellent thermal stability and light and weather resistance, improve mechanical properties, and improve thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

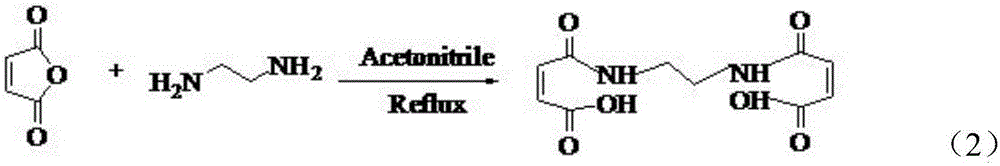

[0028] Weigh maleic anhydride and ethylenediamine respectively in a ratio of 2:1, dissolve maleic anhydride and ethylenediamine in acetonitrile respectively, and dissolve the acetonitrile solution of maleic anhydride drop by drop Add it to the acetonitrile solution of ethylenediamine, stir the reaction until complete precipitation, filter, wash with absolute ethanol, and dry in vacuum to obtain ethylenediamine bismaleamic acid;

[0029] Add the ethylenediamine bismaleamic acid prepared above and sodium hydroxide of twice the amount of the substance into methanol, and react in the methanol solution to obtain a methanol solution of sodium ethylenediamine bismaleamic acid;

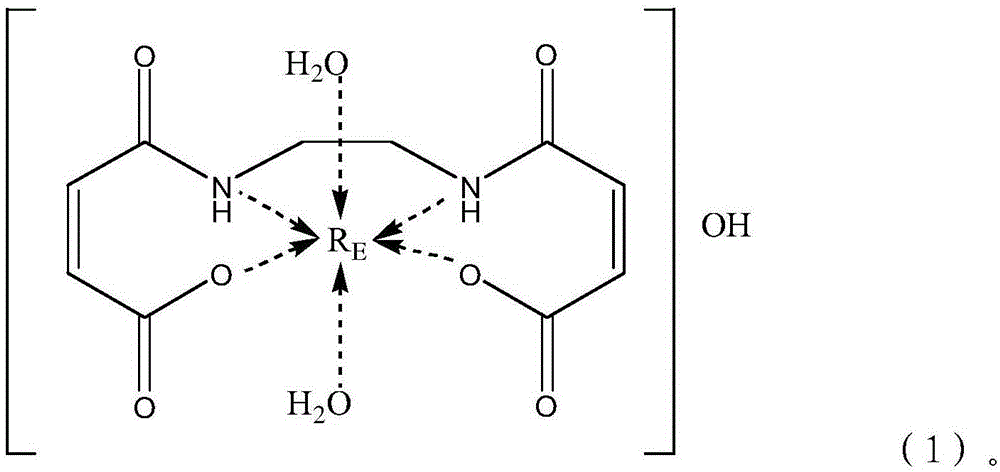

[0030] Take a certain amount of methanol solution of sodium ethylenediamine bismaleamate, adjust the pH value to 7-8, and then add methanol solution of lanthanum chloride drop by drop to form a reaction solution, wherein lanthanum chloride and ethylenediamine bismaleamide The mass ratio of sodium maleamate is...

Embodiment 2

[0033] [La(H 2 O) 2 The application of L]OH as a heat stabilizer for polyvinyl chloride

[0034] [La(H) provided by the embodiment of the present invention 1 2 O) 2 ·L]OH can be used as heat stabilizer of polyvinyl chloride, specifically, the application in PVC resin processing is as follows:

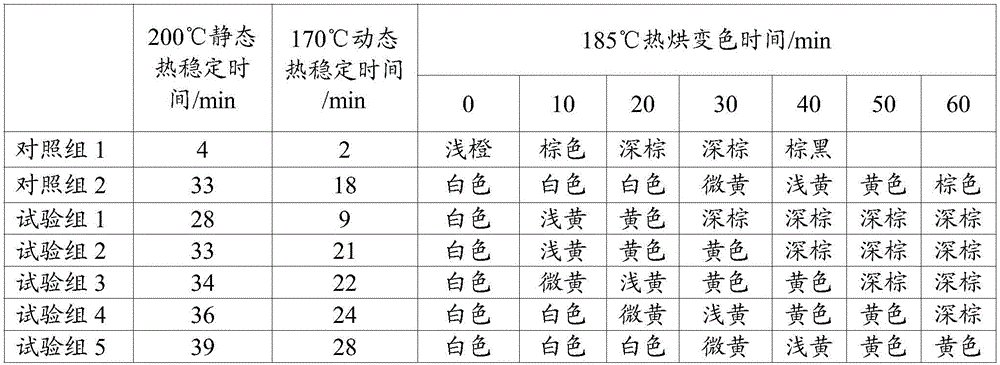

[0035] Test group 1: PVC 100g, DOP 50g, [La(H 2 O) 2 ·L]OH 0.5g, mixed evenly, placed in an oven, and kept at 120°C for 20 minutes to prepare PVC test pieces.

[0036] Test group 2: PVC 100g, DOP 50g, [La(H 2 O) 2 · Mix 1g of L]OH evenly, place in an oven, and keep the temperature at 120°C for 20 minutes to prepare PVC test pieces.

[0037] Test group 3: PVC 100g, DOP 50g, [La(H 2 O) 2 ·L]OH 1.5g, mixed evenly, placed in an oven, and kept at 120°C for 20 minutes to prepare PVC test pieces.

[0038] Test group 4: PVC 100g, DOP 50g, [La(H 2 O) 2 ·L]OH 2g, mixed evenly, placed in an oven, and kept at 120°C for 20 minutes to obtain a PVC test piece.

[0039] Test group 5: PVC ...

Embodiment 3

[0070] Weigh maleic anhydride and ethylenediamine respectively in a ratio of 2:1, dissolve maleic anhydride and ethylenediamine in acetonitrile respectively, and dissolve the acetonitrile solution of maleic anhydride drop by drop Add it to the acetonitrile solution of ethylenediamine, stir the reaction until complete precipitation, filter, wash with absolute ethanol, and dry in vacuum to obtain ethylenediamine bismaleamic acid;

[0071] Add the ethylenediamine bismaleamic acid prepared above and potassium hydroxide of 2 times the amount of the substance into methanol, and react in the methanol solution to obtain a methanol solution of potassium ethylenediamine bismaleamate;

[0072] Take a certain amount of methanol solution of potassium ethylenediamine bismaleamate, adjust the pH value to 7-8, and then add a methanol solution of samarium chloride drop by drop to form a reaction solution, wherein samarium chloride and ethylenediamine bismaleamide The substance ratio of potassi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com