Separation technology for multiple components in ginkgo leaf

A separation technology, the technology of ginkgo biloba, which is applied in the field of separation of multi-components of ginkgo biloba, can solve the problem of excessive toxic phenolic acid in ginkgo leaf extract, achieve high purity, solve the problem of excessive toxic phenolic acid, and good separation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

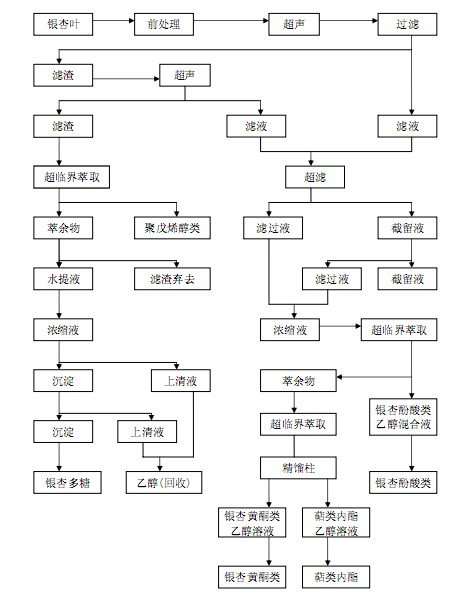

Method used

Image

Examples

Embodiment 1

[0021] Embodiment 1: Ginkgo biloba component separation

[0022] Raw materials: 3-year-old ginkgo leaves picked in June.

[0023] step:

[0024] (1) Remove impurities from the ginkgo leaves, dry until the water content is ≤5%, pulverize, and weigh 3000g of ginkgo leaves of 10-24 mesh.

[0025] (2) Add 10 times the amount of 85% ethanol to impregnate for 60 minutes, extract for 30 minutes under the condition of ultrasonic power 2800W, 42°C, and then filter; the filter residue is then ultrasonically extracted with 10 times the amount of 70% ethanol, the conditions are the same as above, filtered and combined The filtrate was used twice.

[0026] (3) The filter residue of step (2) is subjected to supercritical CO 2 Extraction, the conditions are: extraction kettle pressure 26MPa, extraction temperature 52°C; separation temperature 40°C, first-stage separation kettle pressure 9MPa, second-stage separation kettle pressure 6MPa, CO 2 Flow rate 2.2L / min (food grade, purity ≥ 99.5...

Embodiment 2

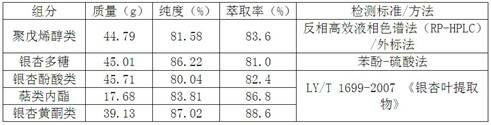

[0031] Embodiment 2: Ginkgo biloba component separation result

[0032] Each component obtained in Example 1 was detected and analyzed, and its compound quality, purity, and extraction rate are shown in Table 1.

[0033] Table 1 Separation results of Ginkgo biloba components

[0034]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com