Preparation method of silver/titanium dioxide compound

A titanium dioxide and composite technology, which is applied in the field of preparation of silver/titanium dioxide composites, can solve the problems of difficult large-scale industrial production, cumbersome preparation process, unfavorable popularization and application, etc., and achieves improved photocatalytic activity, simple operation, and large specific surface area. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

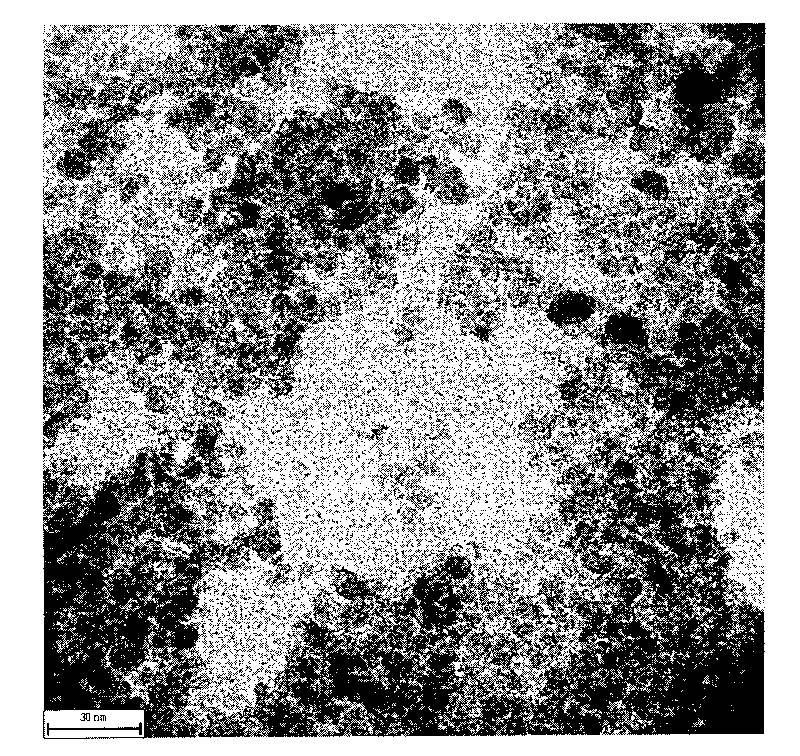

Image

Examples

Embodiment 1

[0016] Take by weighing 16 milligrams of nano-silver and put it into a 100 milliliter small beaker, add a molar concentration of 10 -4 20 ml of anhydrous ethanol solution of M polyvinylpyrrolidone k30, placed in an ultrasonic cell pulverizer, ultrasonically treated for 10 minutes under the condition of ultrasonic power of 500W, placed on a magnetic stirrer, and 6 ml of titanium was slowly added during the stirring process Acetate butyl ester, get 26 milliliters of mixed liquids, then slowly add dropwise with absolute ethanol, deionized water in the ratio of 1:1 and mix fully with nitric acid to become 8 milliliters of mixed solutions that pH value is 2 under the situation of stirring, Stir at 40°C for 2 hours, put it in a drying oven and dry at 80°C for 24 hours, then put it into a horse-shaped furnace and bake at 400°C for 10 hours to obtain about 1.4 grams of silver / titanium dioxide composite.

[0017] Determination results: The prepared silver / titanium dioxide composite was...

Embodiment 2

[0019] Take by weighing 16 milligrams of nano-silver and put it into a 100-milliliter beaker, and add it with a molar concentration of 10 in the beaker. -3 40 ml of ethanol solution of M polyvinylpyrrolidone k30, placed in an ultrasonic cell pulverizer and ultrasonically treated for 50 minutes under the condition of ultrasonic power of 100W, then placed on a magnetic stirrer, slowly added 4 ml of titanic acid during heating and stirring butyl ester, to obtain 44 milliliters of mixed liquid, then add absolute ethanol and deionized water to mix thoroughly in a ratio of 1:1 and adjust to 10 milliliters of mixed solution with pH value of 2 with nitric acid, stir at 80°C for 1 hour, put Dry it in a drying oven at 120°C for 10 hours, and then put it into a horse-radiation furnace and bake it at a high temperature of 700°C for 2 hours to obtain about 1.0 g of silver / titanium dioxide composite.

[0020] Determination results: The prepared silver / titanium dioxide composite was analyzed...

Embodiment 3

[0022] Take by weighing 30 mg of nano-silver and put it into a 100 ml small beaker, add a molar concentration of 10 to the small beaker -3 19 milliliters of ethanol solution of M polyvinylpyrrolidone k30 was placed on a magnetic stirrer and stirred vigorously for 30 minutes, then, 6 milliliters of butyl titanate was slowly added during the stirring process to obtain 25 milliliters of mixed liquid, and then absolute ethanol, Mix deionized water thoroughly at a ratio of 1:1 and adjust to 10 ml of a mixed solution with a pH value of 3 with nitric acid, stir at 60°C for 1.5 hours, put it in a drying oven and dry it at 90°C for 20 hours, and then put it in Roasting at 500°C for 4 hours in a Mafu furnace can yield about 1.4 grams of silver / titanium dioxide composite.

[0023] Determination results: The prepared silver / titanium dioxide composite was analyzed by Japan Shimadzu-6000X-ray diffractometer to analyze the silver / titanium dioxide composite crystal form, and the Japanese Hita...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com