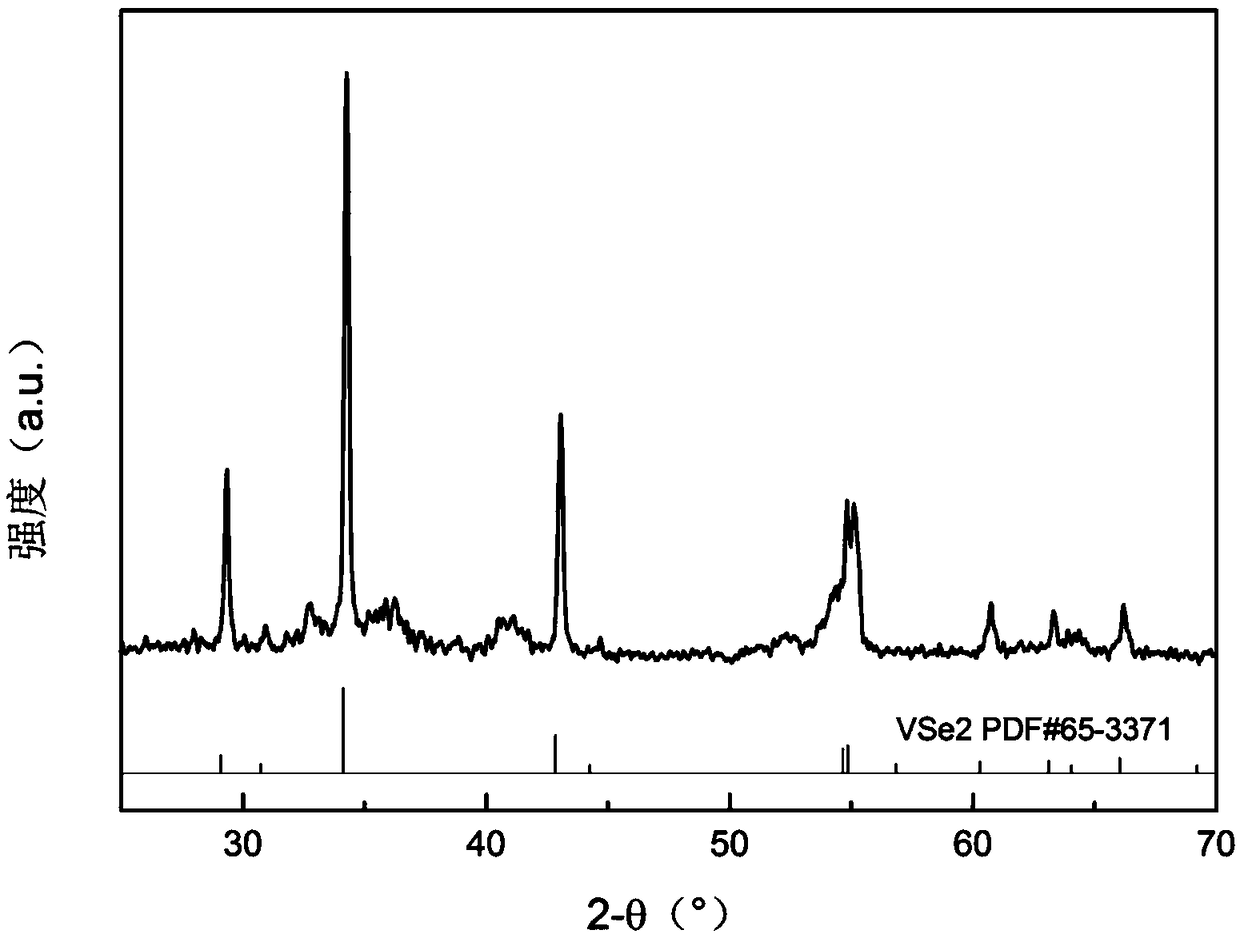

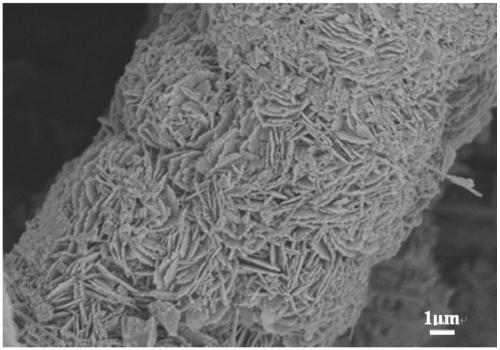

Method for synthesizing self-assembled VSe2 nanosheets

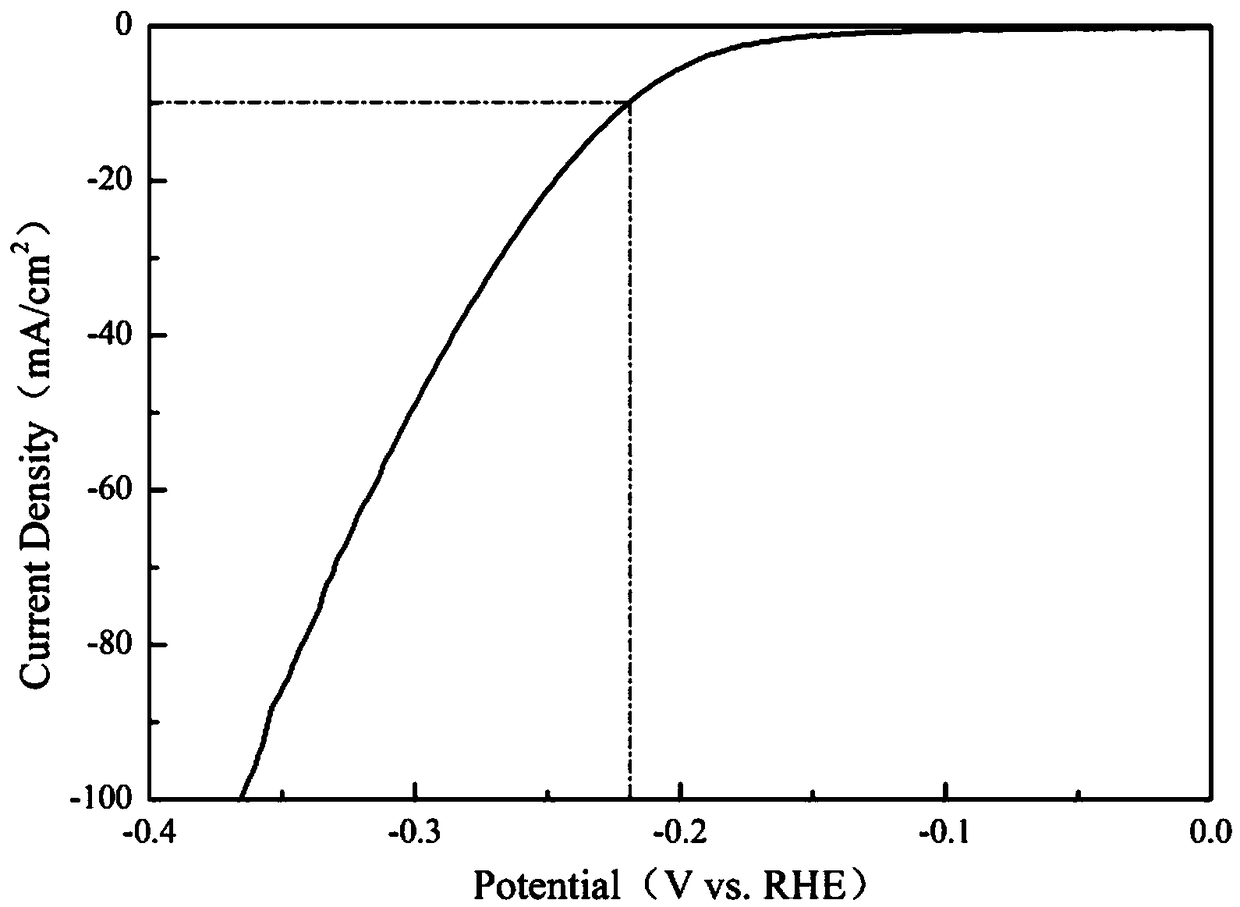

A synthesis method and self-assembly technology, applied in chemical instruments and methods, electrolysis components, hydrogen production, etc., can solve the problems of destroying VSe2 structure, volume change, reducing VSe2 specific capacity and cycle stability, etc. The reaction is fully carried out and is conducive to the effect of electron transport

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] 1) Insulate carbon cloth (1cm×3cm) at 120°C for 1 hour under nitric acid reflux, cool to room temperature, wash with water and alcohol several times, and vacuum dry for later use;

[0032] 2) Weigh selenourea and vanadium pentoxide at a molar ratio of 5:1, i.e. the masses are 615.10 mg and 182.00 mg respectively, and dissolve them in a solution composed of deionized water and absolute ethanol with a volume ratio of 2:1 (total 30mL), magnetically stirred for 1h, and then put in the treated carbon cloth (CC) to obtain the mixed solution;

[0033] 3) Transfer the resulting mixed solution in step 2) to a 50mL high-temperature and high-pressure reactor with a polyparaphenylene liner, then add 0.030g of polyvinylpyrrolidone and 0.400g of hexadecyl to the reactor Trimethylammonium bromide, 0.015g of ammonium fluoride morphology control agent, the reaction kettle is sealed, placed in an oven at 220 ° C for 20h;

[0034] 4) After the reaction is finished, after cooling down to ...

Embodiment 2

[0038] 1) Insulate carbon cloth (1cm×3cm) at 120°C for 1 hour under nitric acid reflux, cool to room temperature, wash with water and alcohol several times, and vacuum dry for later use;

[0039] 2) Weigh selenourea and ammonium metavanadate with a molar ratio of 3:1, i.e. the masses are 369.05 mg and 116.98 mg respectively, and dissolve it in a solution composed of deionized water and absolute ethanol with a volume ratio of 3:1 (total 30mL), magnetically stirred for 1h, and then put in the treated carbon cloth (CC) to obtain the mixed solution;

[0040] 3) Transfer the resulting mixed solution in step 2) to a 50mL high-temperature and high-pressure reactor with a polyparaphenylene liner, then add 0.363g of polyvinylpyrrolidone and 0.355g of hexadecyl to the reactor Trimethylammonium bromide, 0.025g of ammonium fluoride morphology control agent, seal the reaction kettle, place in an oven and react at 180°C for 25h;

[0041] 4) After the reaction is finished, cool down to room...

Embodiment 3

[0045] 1) Insulate carbon cloth (1cm×3cm) at 120°C for 1 hour under nitric acid reflux, cool to room temperature, wash with water and alcohol several times, and vacuum dry for later use;

[0046] 2) Weigh selenourea and ammonium metavanadate at a molar ratio of 2:1, i.e. the masses are 246.04 mg and 157.30 mg respectively, and dissolve it in a solution composed of deionized water and absolute ethanol with a volume ratio of 1:1 (total 30mL), magnetically stirred for 1h, and then put in the treated carbon cloth (CC) to obtain the mixed solution;

[0047] 3) Transfer the resulting mixed solution in step 2) to a 50mL high-temperature and high-pressure reactor with a polyparaphenylene liner, then add 0.025g of polyvinylpyrrolidone and 0.455g of hexadecyl to the reactor Trimethylammonium bromide, 0.005g of ammonium fluoride morphology control agent, seal the reaction kettle, place in an oven and react at 210°C for 21h;

[0048] 4) After the reaction is finished, cool down to room t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com