Equipment and method for producing metal nanometer power by automatic control DC electric arc

A technology of metal nano-powder and DC arc, applied in the field of nano-material preparation, to achieve novel structure, improve quality, and overcome unstable factors in the production process and powder quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

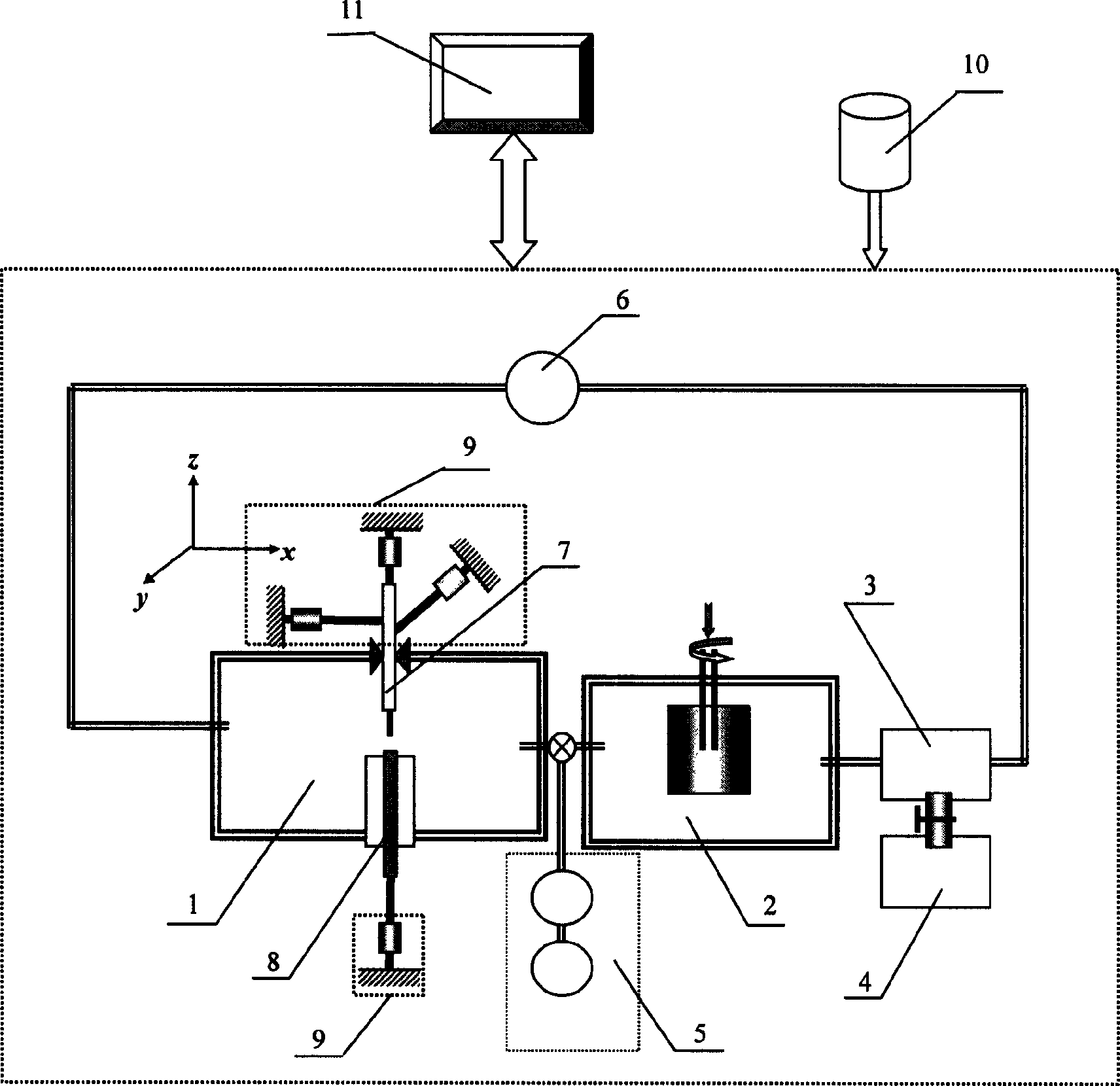

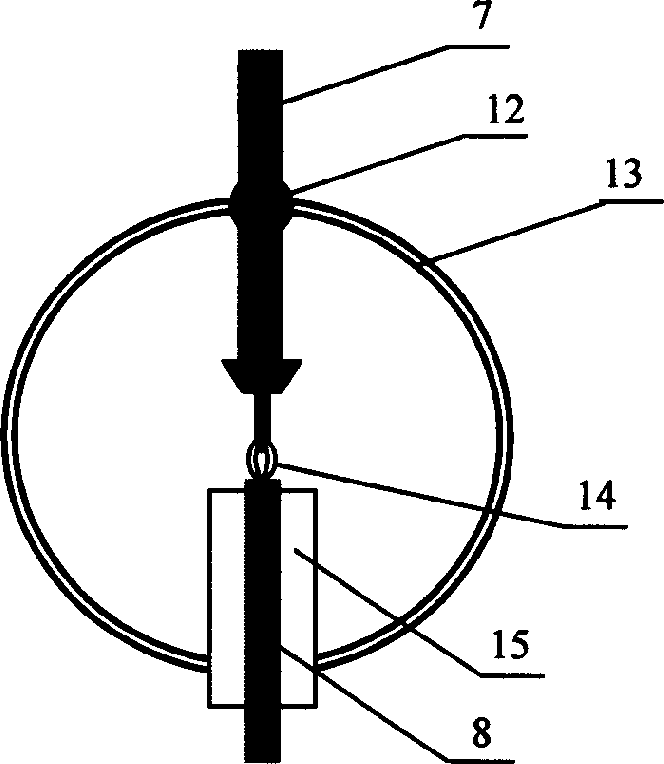

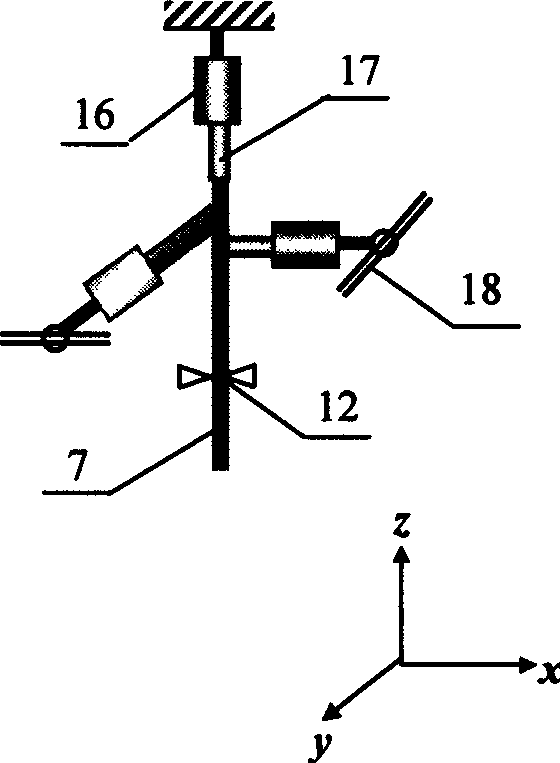

[0020] An automatic control direct current arc metal nano powder production equipment, which is composed of a powder generation chamber 1, a powder particle size classification chamber 2, a powder collection chamber 3, a powder processing chamber 4, a vacuum system 5, and a gas circulation pump connected in sequence 6. The hydraulic transmission system 9, the water cooling system 10, and the programming control system 11 are composed; the anode 8 and the cathode 7 are installed in the powder generation chamber 1, and are connected to the external hydraulic transmission and programming control system through the wall of the powder generation chamber 1; The particle size classification chamber 2 is composed of a double-walled water-cooled shell and a liquid nitrogen cooling tank; the hydraulic transmission system 9 is composed of a hydraulic tank and a transmission rod that control the 73-dimensional movement of the cathode and the 81-dimensional movement of the anode; the program...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com