Satellite structure and satellite assembly method

A satellite structure and satellite technology, applied in the field of aerospace satellites, can solve the problems of low satellite disassembly efficiency, difficult disassembly, and narrow operation space, and achieve the effect of improving the efficiency of satellite assembly and disassembly, and widely used value.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0036] For the installation of the intermediate board 16, it can be realized through the following two specific implementation methods:

Embodiment approach 1

[0038] The installation method of each intermediate board 16 is the same as that of the front side board 12, rear side board 13, left side board 14, and right side board 15. Specifically, the lower cover board 11 is inserted in each middle board. The installation position corresponding to the board 16 is provided with at least two second positioning pins (not shown in the figure), and each of the intermediate boards 16 is provided with a second positioning hole corresponding to the second positioning pins (in the figure not shown), the intermediate board 16 and the lower cover 11 are installed and positioned based on the second positioning pin and the second positioning hole. Preferably, the first locating pin 4 and the second locating pin are the same model locating pins, such as Figure 4 Locating pins shown.

Embodiment approach 2

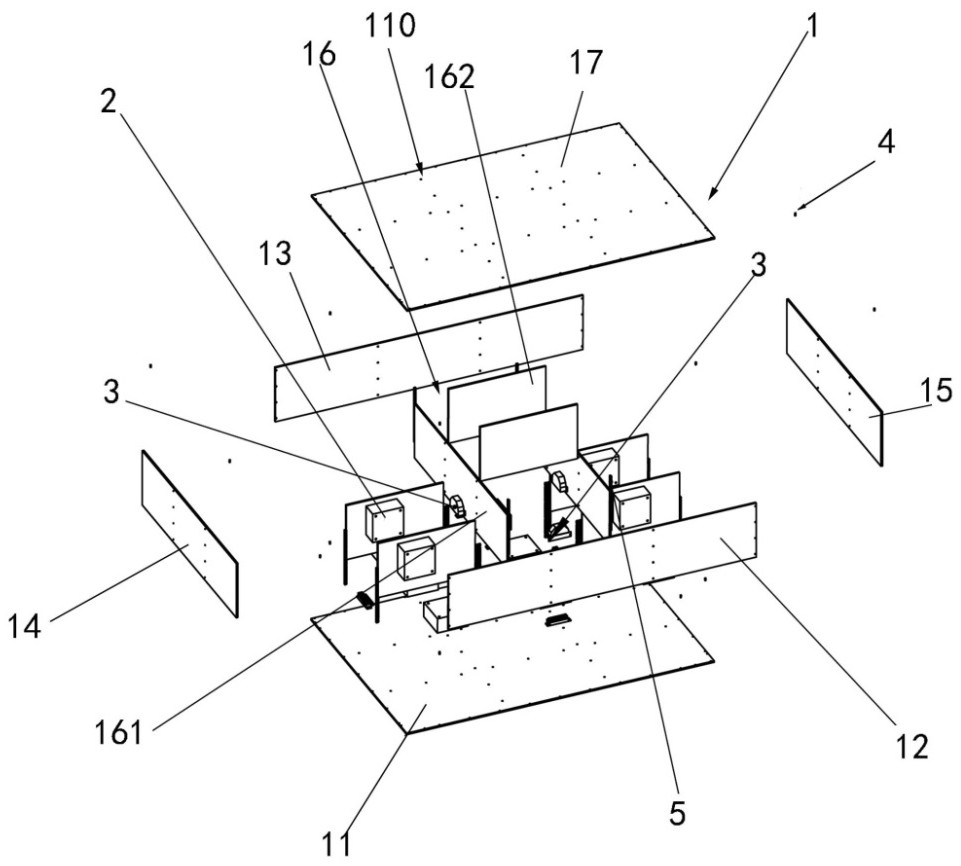

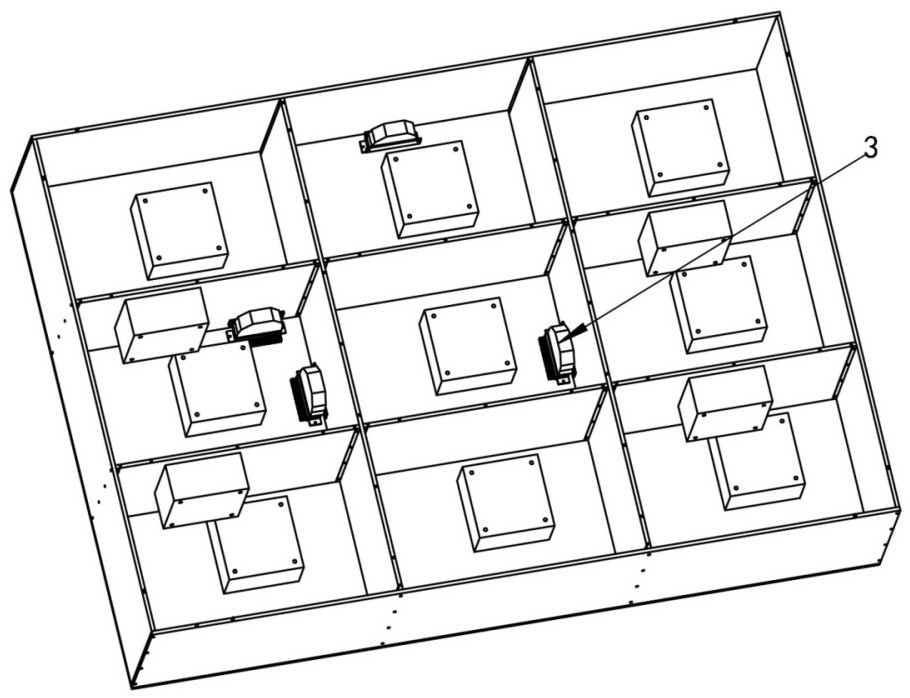

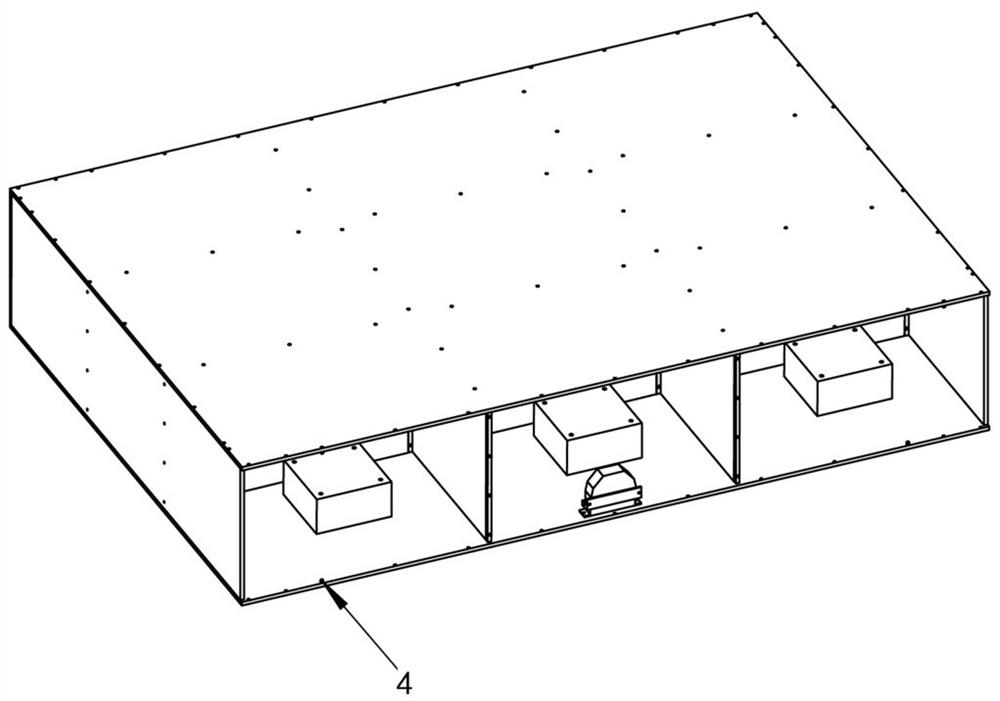

[0040] Such as figure 1 The satellite structure shown, the satellite structure also includes a plurality of docking bosses 5, and the enlarged view of the docking bosses 5 is as follows Figure 5 As shown, both ends of the intermediate board 16 are provided with docking grooves 160 corresponding to the docking boss 5, as Figure 6 As shown, when the satellite deck 1 is a single plate structure, the docking boss 5 is installed on the corresponding position of the satellite deck 1 according to the preset satellite structure layout, when the front side plate 12, After the rear side plate 13, the left side plate 14, and the right side plate 15 are installed on the lower cover plate 11, install the first intermediate insert plate 161 on the Corresponding positions in the box structure, after all the first intermediate boards 161 are installed, the second intermediate boards are installed in the box structure based on the docking groove 160 and the docking boss 5 plug-in structure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com