Cutting die automatic production method capable of achieving continuous machining

A production method and cutting die technology, applied in simulators, instruments, computer control, etc., can solve problems such as over-cutting or under-cutting of the cone cutter, difficulty in keeping the size of the cone cutter consistent, and difficult compensation of cutter deviation, etc., to ensure continuous The effect of realizing automatic batch production, improving processing accuracy and processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

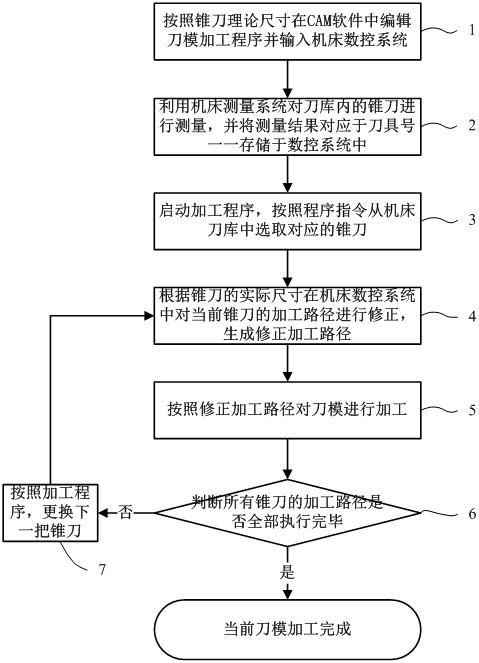

[0029] like figure 1 As shown, a kind of cutting mold automatic production method that can realize continuous processing of the present invention comprises:

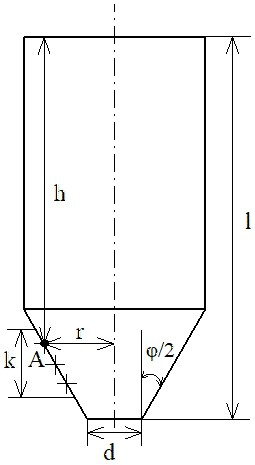

[0030] Step 1, determine the number N of conical cutters used and the theoretical size parameters of each conical cutter according to the characteristics of the cutter die, edit and generate a cutter die processing program in the CAM software and input it into the CNC system of the machine tool; in the processing program, each cone The tool compensation command of the current conical tool is set before the machining path of the tool starts;

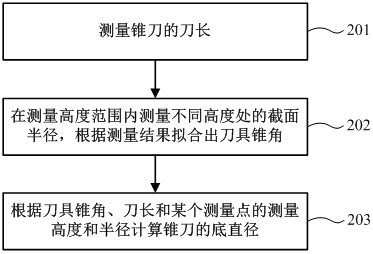

[0031] Step 2: Load the conical cutters used in the machining program into the tool magazine of the machine tool, and use the machine tool measurement system to measure the conical cutters in the tool magazine one by one, and store the mea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com