EMMC automatic mass production method and device, storage medium and electronic equipment

A mass production and automatic feeding technology, applied in static memory, instruments, software deployment, etc., can solve problems such as high labor intensity, operational errors, and low production efficiency, and achieve the goal of reducing labor costs, avoiding losses, and improving production efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

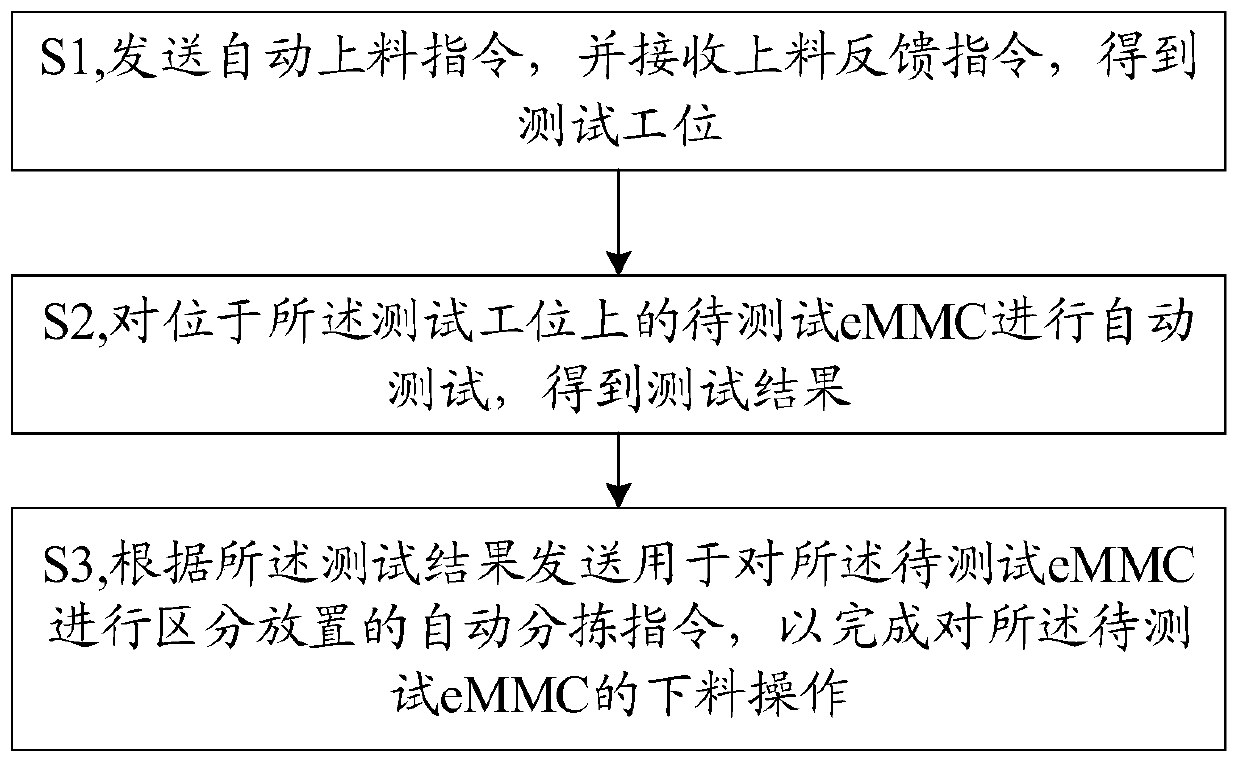

[0078] According to the above, combined with figure 1 , the specific description of embodiment one of the present invention is as follows:

[0079] An eMMC automated mass production method, comprising:

[0080] S1. Send an automatic loading command and receive a feeding feedback command to obtain a test station;

[0081] Specifically, the execution end is the test computer where the mass production software is located. The test computer sends an automatic loading command to the industrial control computer, and the industrial control computer receives and executes the automatic loading command to control the robotic arm to grab the eMMC to be tested and install it on the hub board. When the eMMC to be tested is installed, the industrial control computer sends a feeding feedback command to the test computer. The test computer receives the feeding feedback command in real time. The feeding feedback command includes a signal string, and each digital digit on the signal string co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com