An over-limit ink dot anti-counterfeiting method and a printed matter

A technology for printed matter and ink dots, which is applied in the field of over-limit ink dot anti-counterfeiting, can solve the problem of inability to print out width over-limit dots, etc., and achieves the effect of improving the anti-counterfeiting query rate, improving the accuracy rate and simplifying the production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

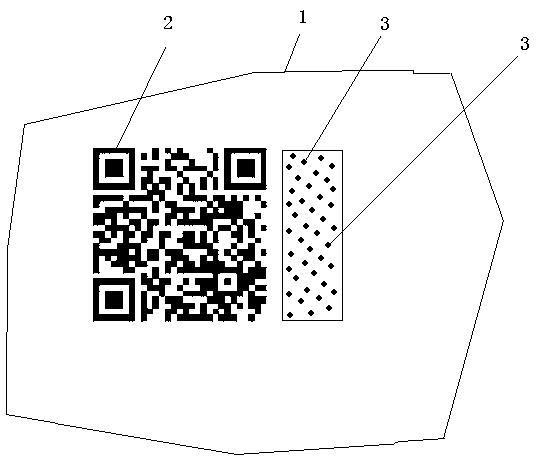

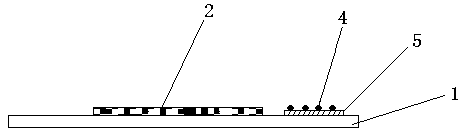

[0054] first step, such as figure 1 As shown, on the printing surface of the printed matter having wetting properties relative to the ink, some ink dot matrixes with a width (including length) of 0.06 mm formed by the ink are printed. And at least one unique code is printed for each printed matter.

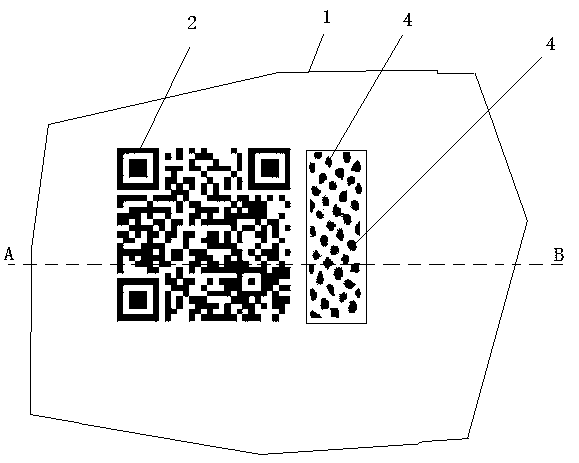

[0055] In the second step, diluent is added to reduce the surface tension of the ink, so that the ink dot matrix can be randomly spread along the printing surface under the action of the positive wetting force, and the deformation can be enlarged (such as figure 2 As shown) dot matrix of ink sticks of random shape, and make the width of some ink sticks<twice the width of ink dots; wherein, the width of ink dots<the width of some ink sticks<twice the width of ink dots.

[0056] In order to save the layout and not to change the version, the local area in the printing ink layer of the code can be arranged with ink dots, and the ink dots (3) can also be designed in the blank gaps i...

Embodiment 2

[0062] Such as Figure 4 As shown, on the printing surface of the printed matter with negative wetting characteristics relative to the ink, some codes formed by the ink dots with a width (ie diameter) of 0.3 mm and arranged in a dot matrix are printed.

[0063] In the second step, a tension regulator is added to enhance the surface tension of the ink, so that the ink dot matrix is opened along the negative direction of the printing surface under the action of the negative wetting force, and the ink dot matrix is reduced into a randomly shaped ink dot matrix by deformation.

[0064] In order to be able to use some unsuitable printing materials to print printed matters, a partial wetting coating can be pre-printed on the printing material where the ink dot matrix is located, and the ink dot matrix is printed on the partial wetting coating.

[0065] The third step is to prepare an industrial-grade optical macro lens and digital camera, zoom in and shoot (for example, 20 t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com