Non-destructive testing method for formaldehyde content of textiles

A formaldehyde content, non-destructive testing technology, applied in the inspection of textile materials, textile and papermaking, color/spectral property measurement, etc., can solve the problems of low accuracy and reliability, damage to textile products, inconsistent results, etc. High accuracy and reliability, improved volatilization speed, wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0147] 1 Test method:

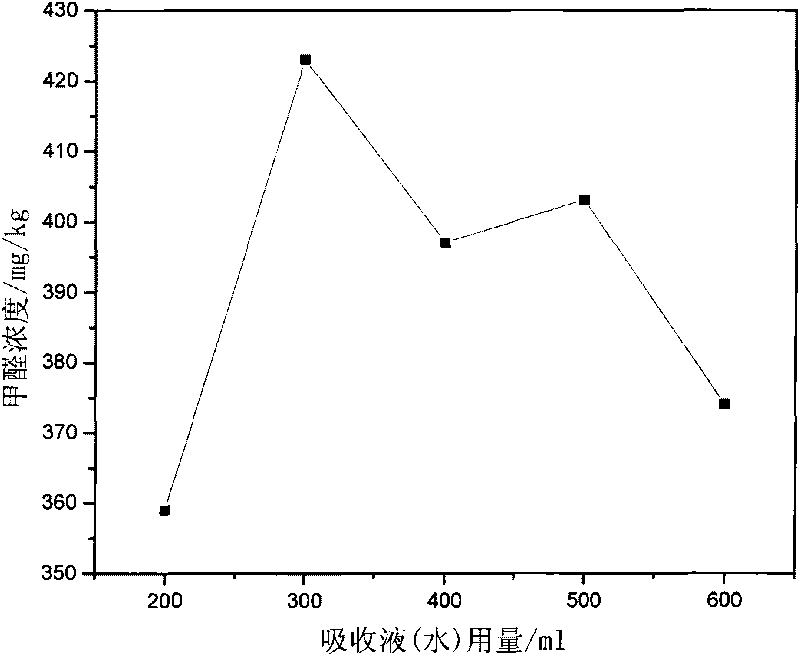

[0148] (1) Put the whole textile to be tested in a closed container, put the whole textile into the closed container and spread it as much as possible, then let air into the closed container, and at the same time put the content of the to-be-tested The gas of the volatile matter of the test sample is sent to the absorption container filled with 300ml water, so that the water absorbs the gas from the airtight container; The air velocity is sufficient to equilibrate the pressure in the bottle with atmospheric pressure.

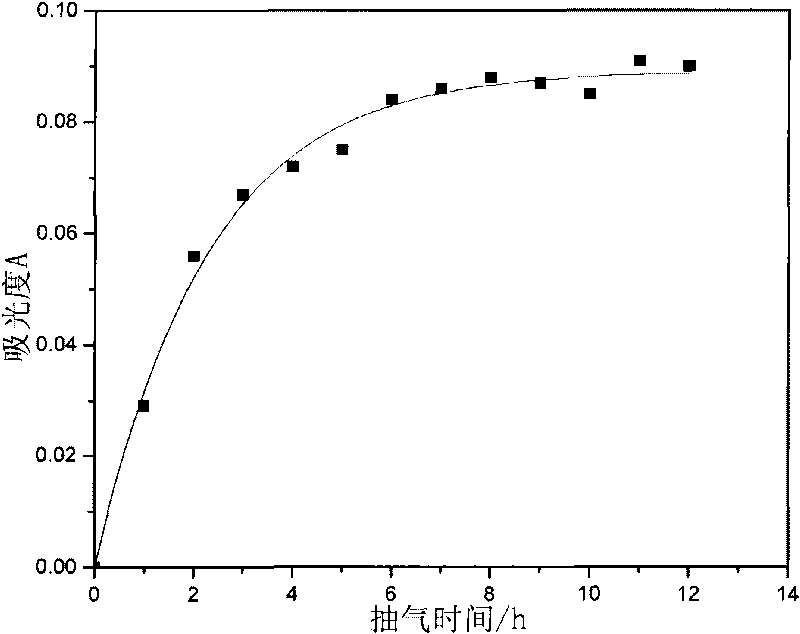

[0149] (2) continuously feed air into the airtight container and send the gas in the airtight container into the water for 6 hours, then stop the process of the water absorbing the gas;

[0150] (3) Take the water that has absorbed formaldehyde in step (2) and measure its absorbance with acetylacetone spectrophotometry, and carry out qualitative identification or quantitative determination of formaldehyde.

[0151] 2 blank samples

[0...

Embodiment 1

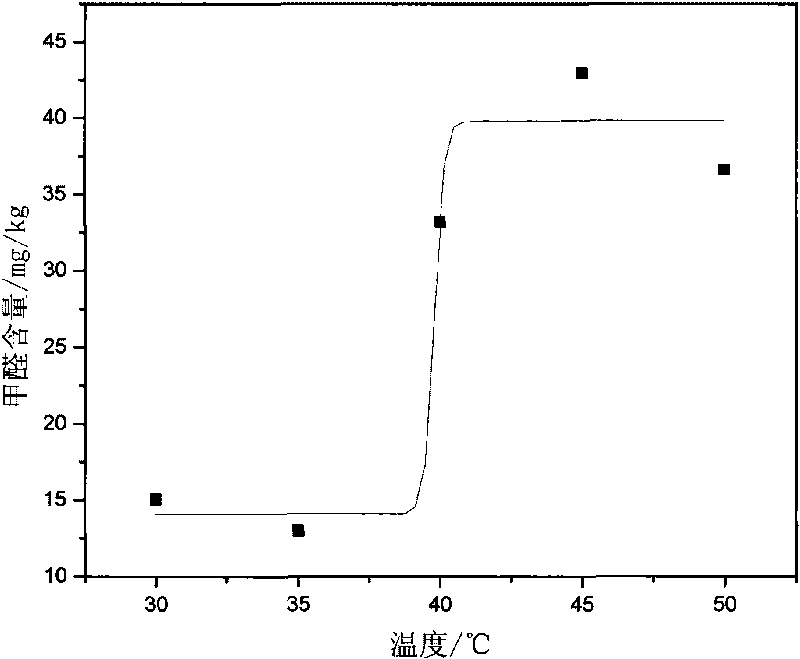

[0154] Example 1: commodity name: knitting pure white cotton overprinting all over the ground; marking number: white pulp GR. The airtight container is kept at 45°C

Embodiment 2

[0155] Embodiment two: commodity name: cloth sample. The airtight container is kept at 40°C

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com