Method of identifying woven fabric defect

A technology for identifying machines and fabrics, which is applied in the inspection of textile materials, character and pattern recognition, computer parts and other directions. rate, good promotion and application prospects, and the effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

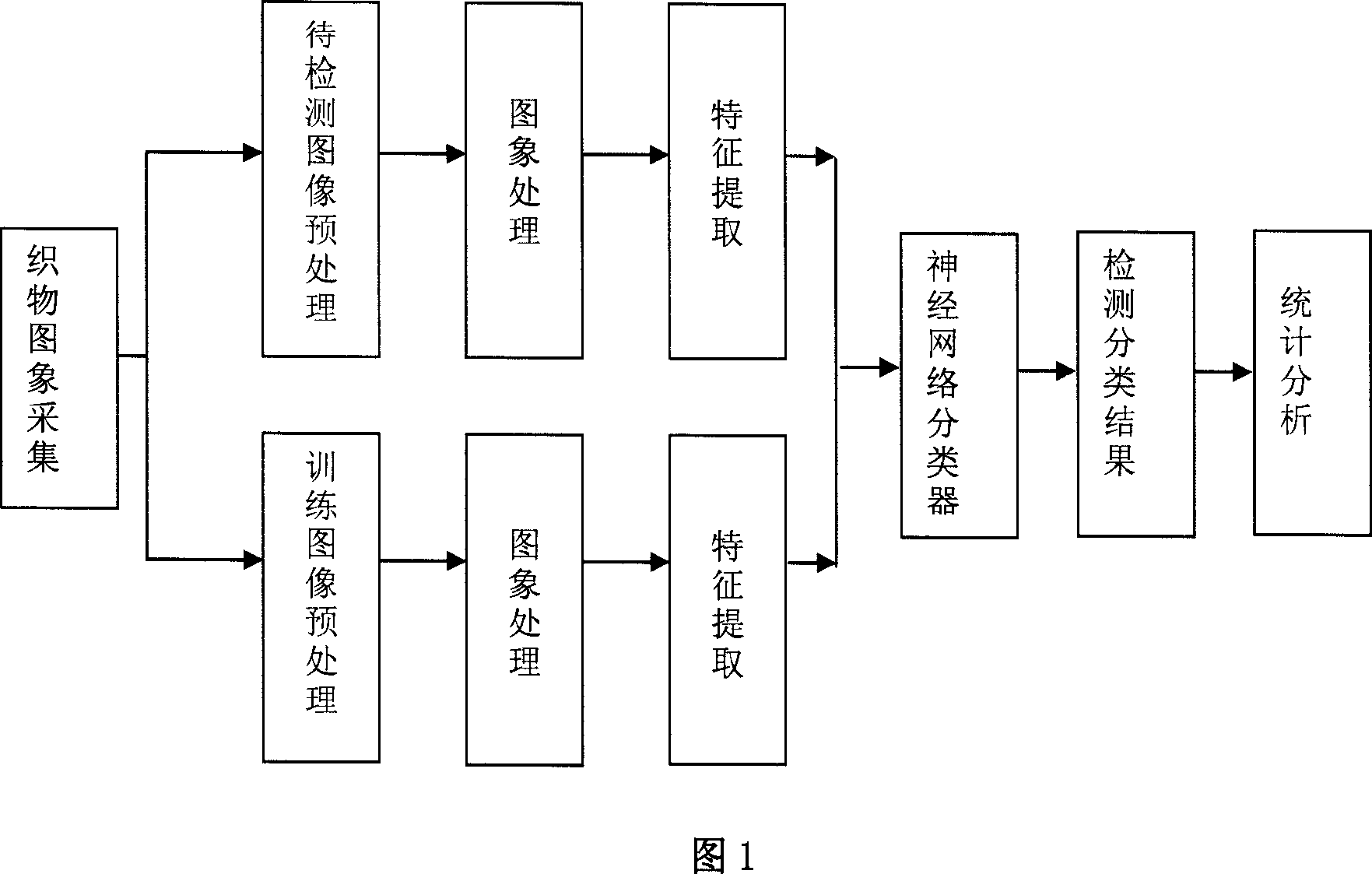

[0016] Referring to accompanying drawing 1, the main process of the method for identifying woven fabric defects described in this embodiment is: collecting defect images, image preprocessing, image analysis and defect detection classification, including training and learning process, detection process, defect automatic detection technology The core content of the paper is the method of processing the collected fabric images.

[0017] The technical solutions of the embodiments of the present invention identify defects in the fabric, which may be warp breaks, weft breaks, weft bars, oil stains, holes, and the like.

[0018] As shown in Figure 1, after the image acquisition system obtains the image, it must first complete the training process, which is used as a neural network training and learning, so that the fabric defect detection system is familiar with the fabric to be detected; after the system is trained, it can enter the detection process. process. In the process of tra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com