Patents

Literature

69results about How to "Realize the effect of automation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

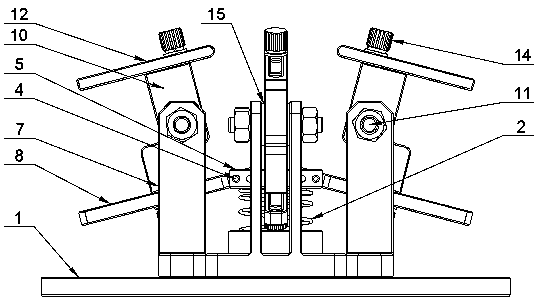

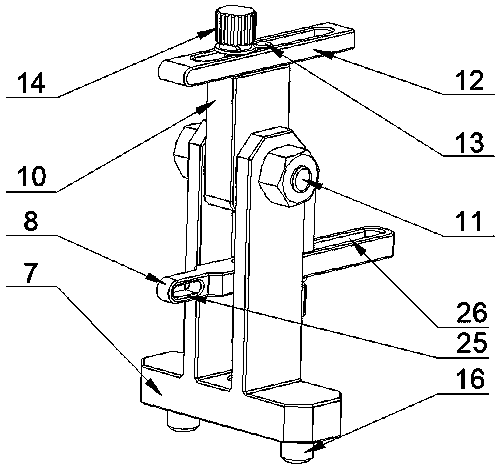

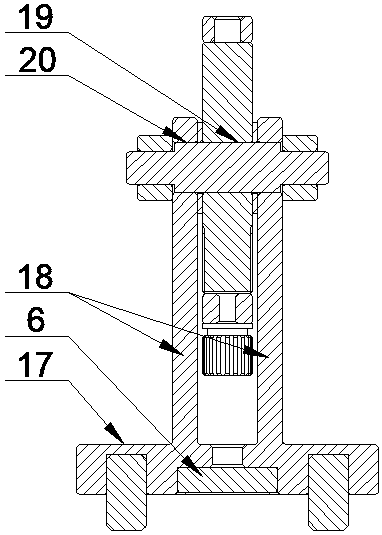

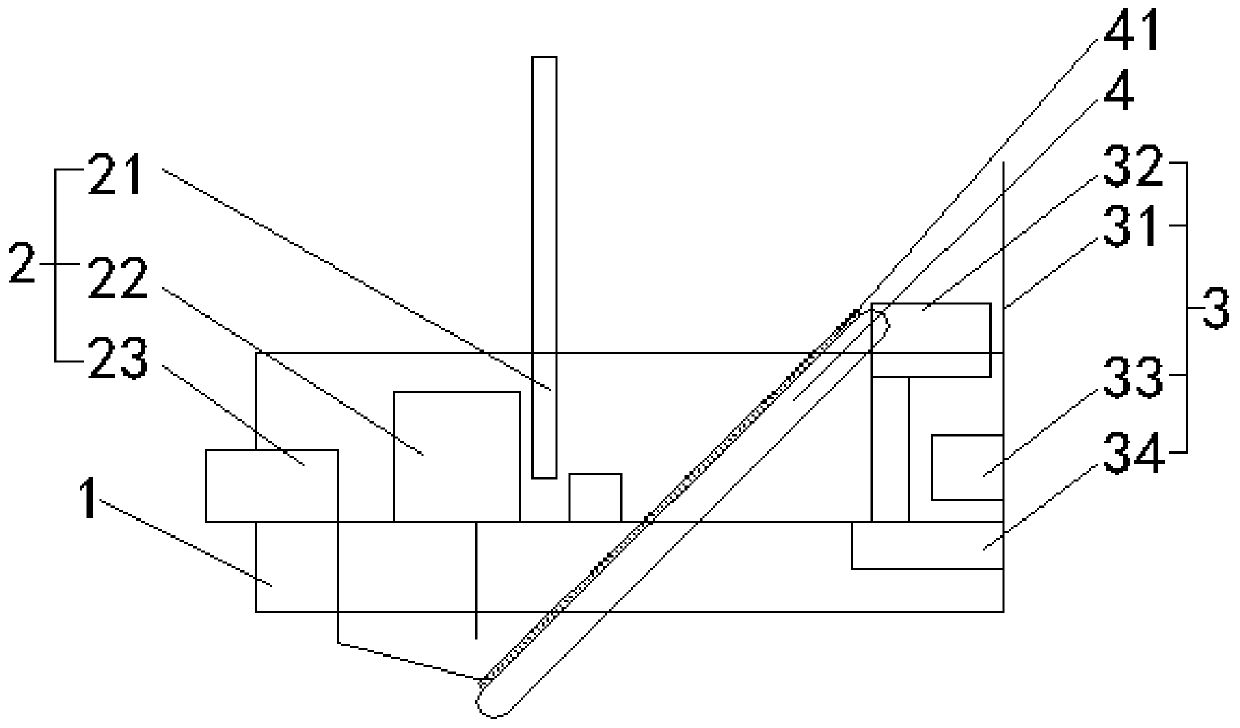

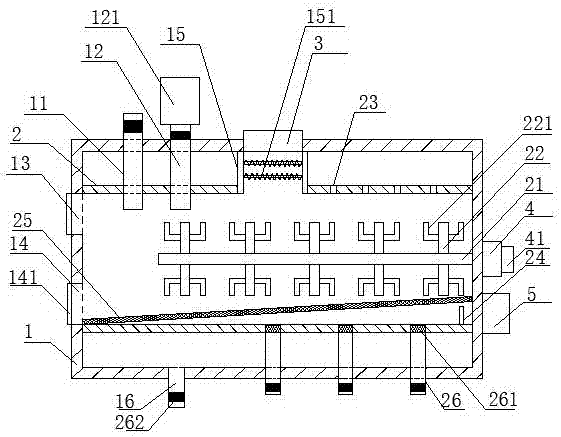

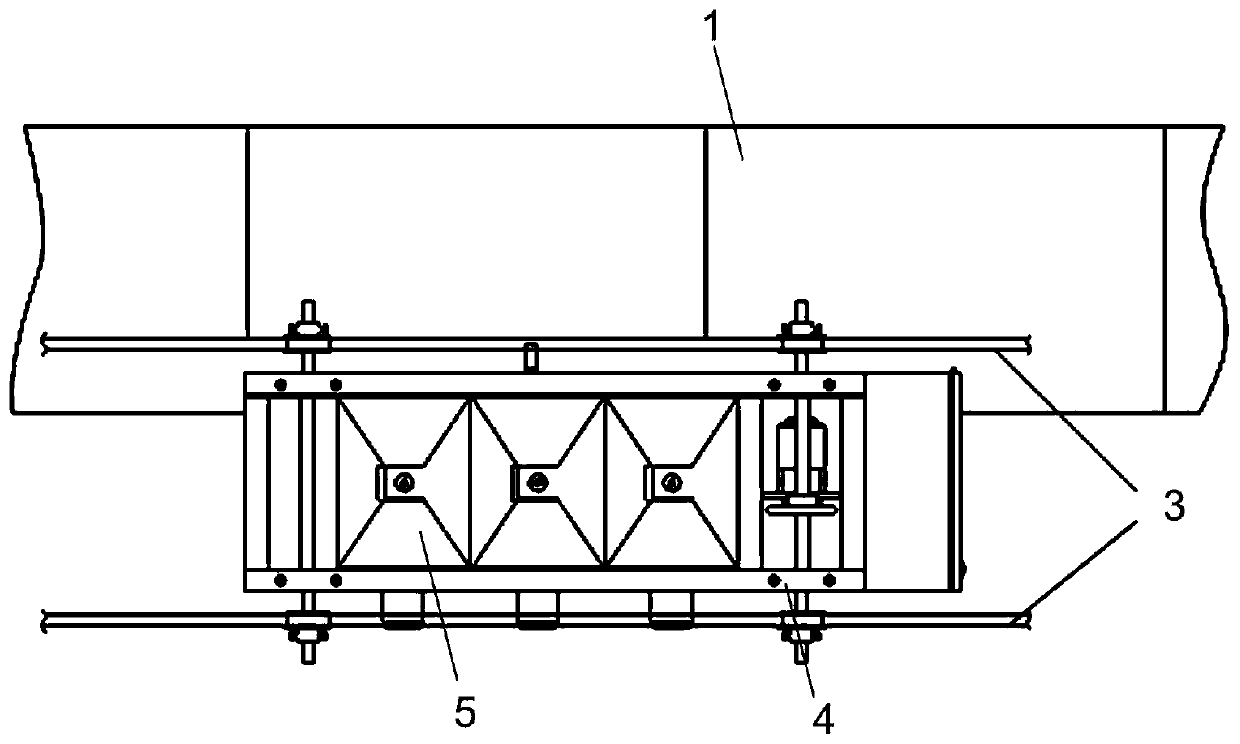

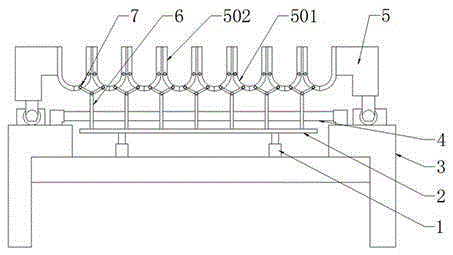

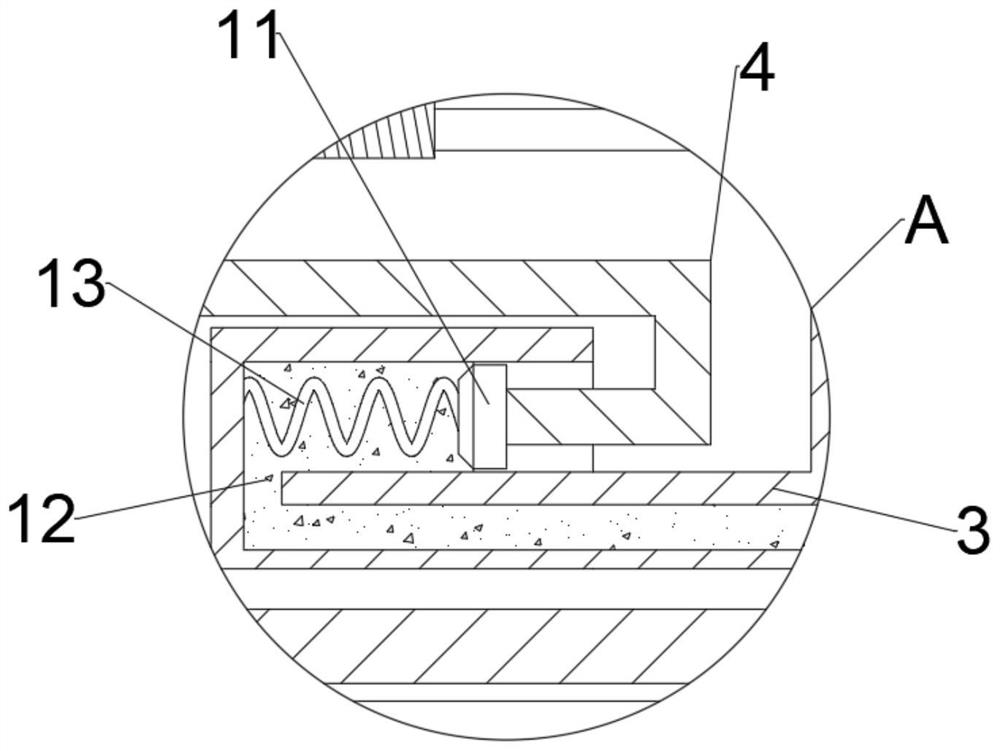

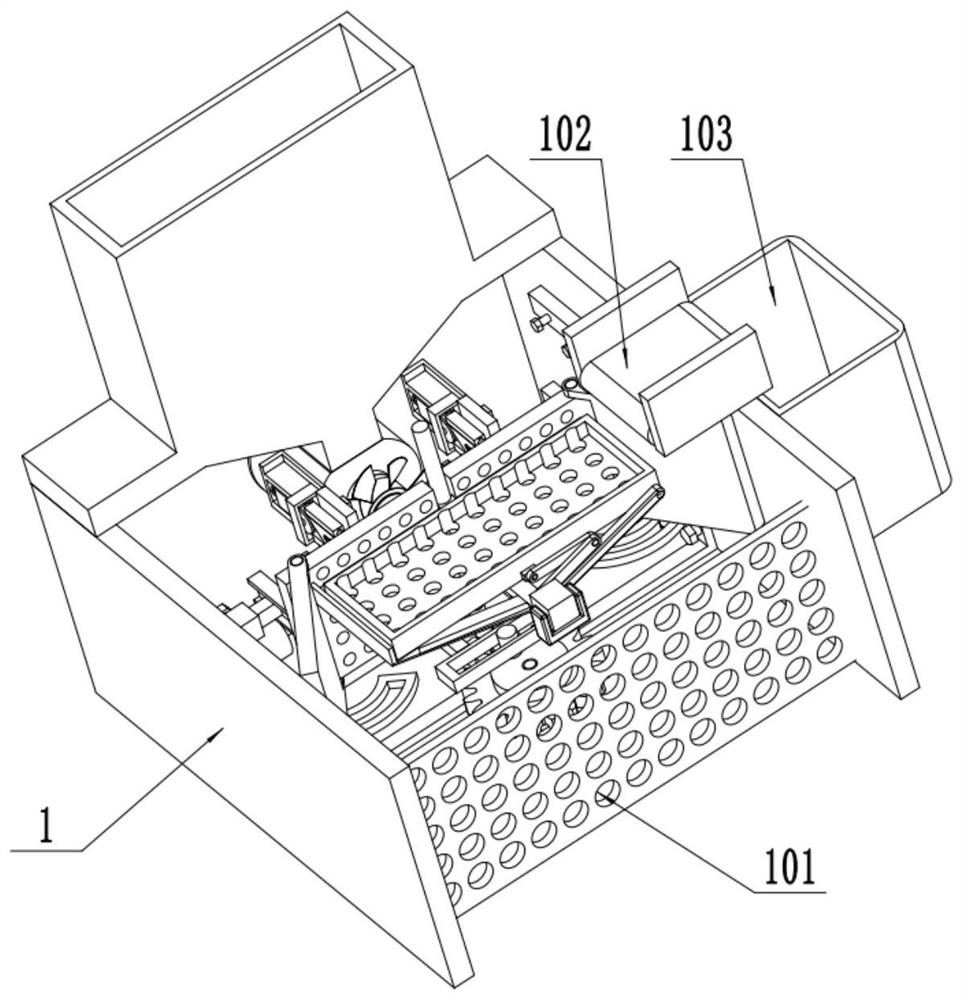

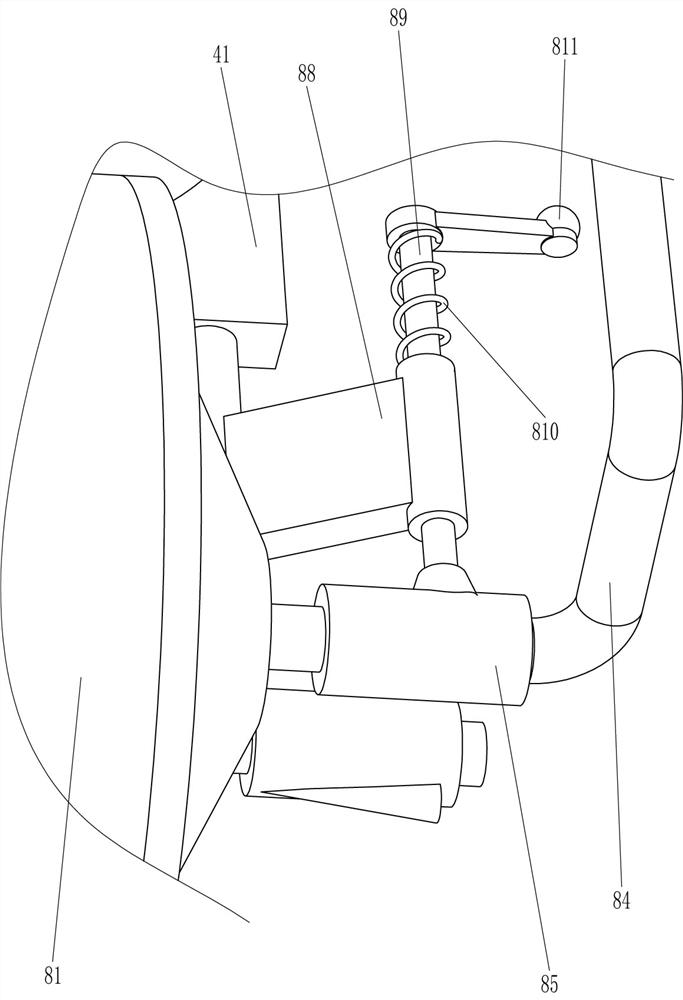

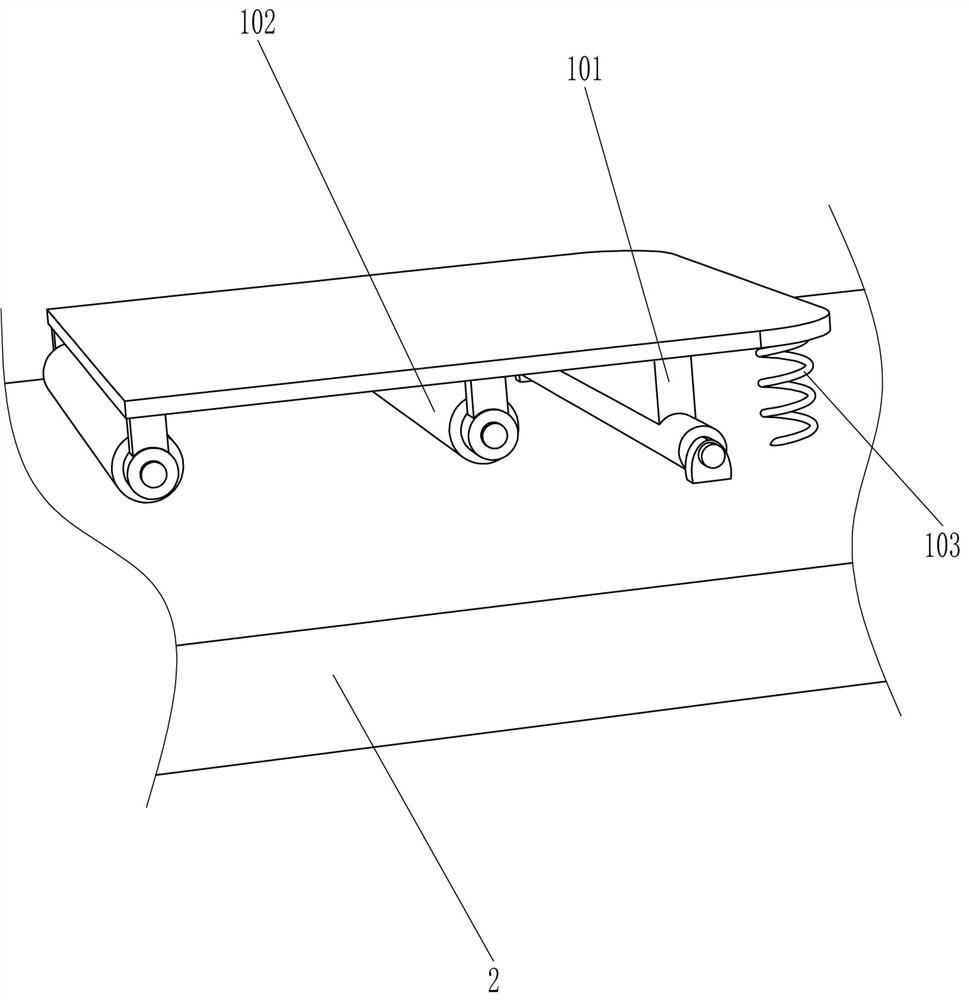

Gravity self-centering self-locking clamp

PendingCN110014315AImplementation intoEasy to grabPositioning apparatusMetal-working holdersModular designSelf locking

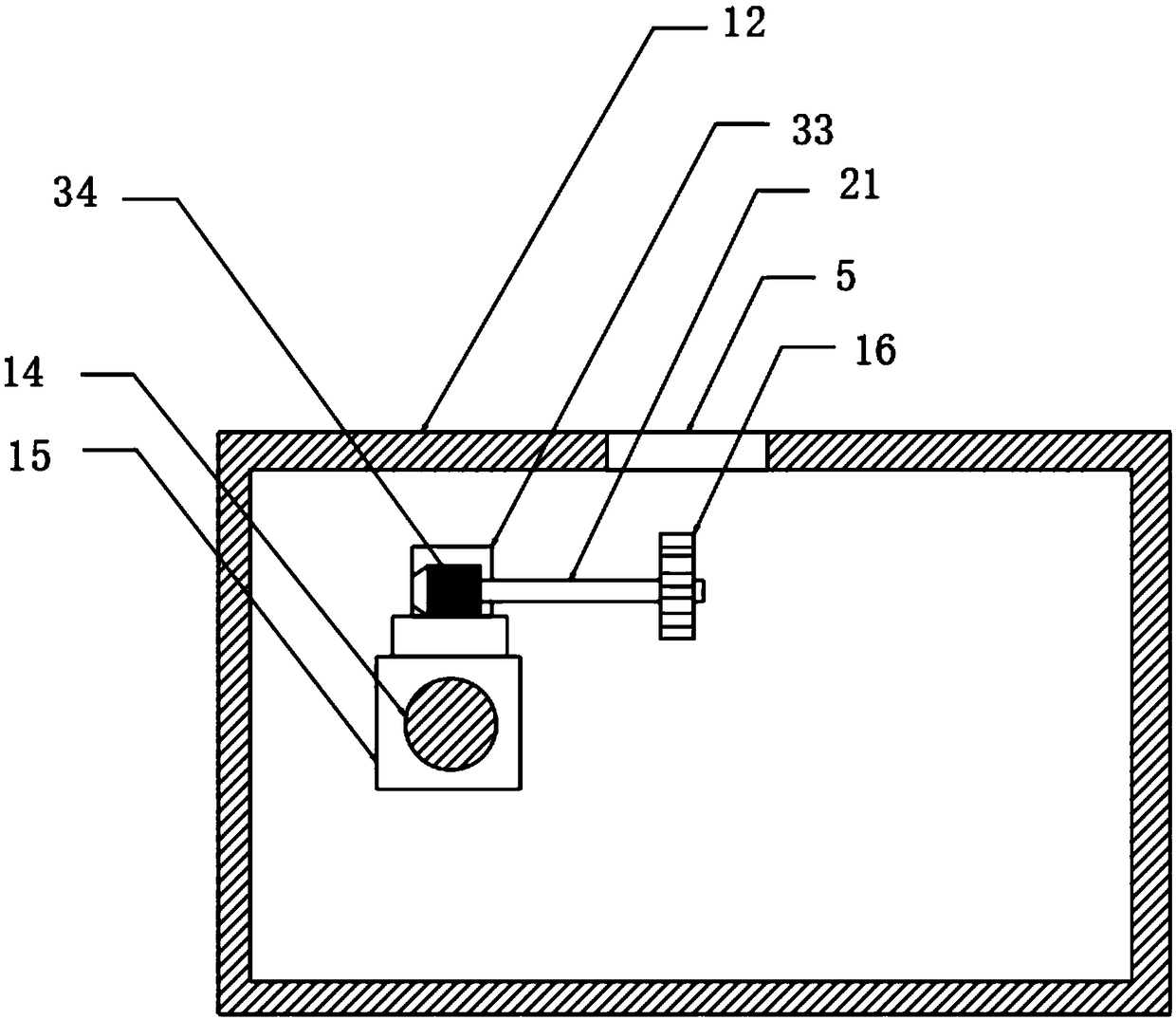

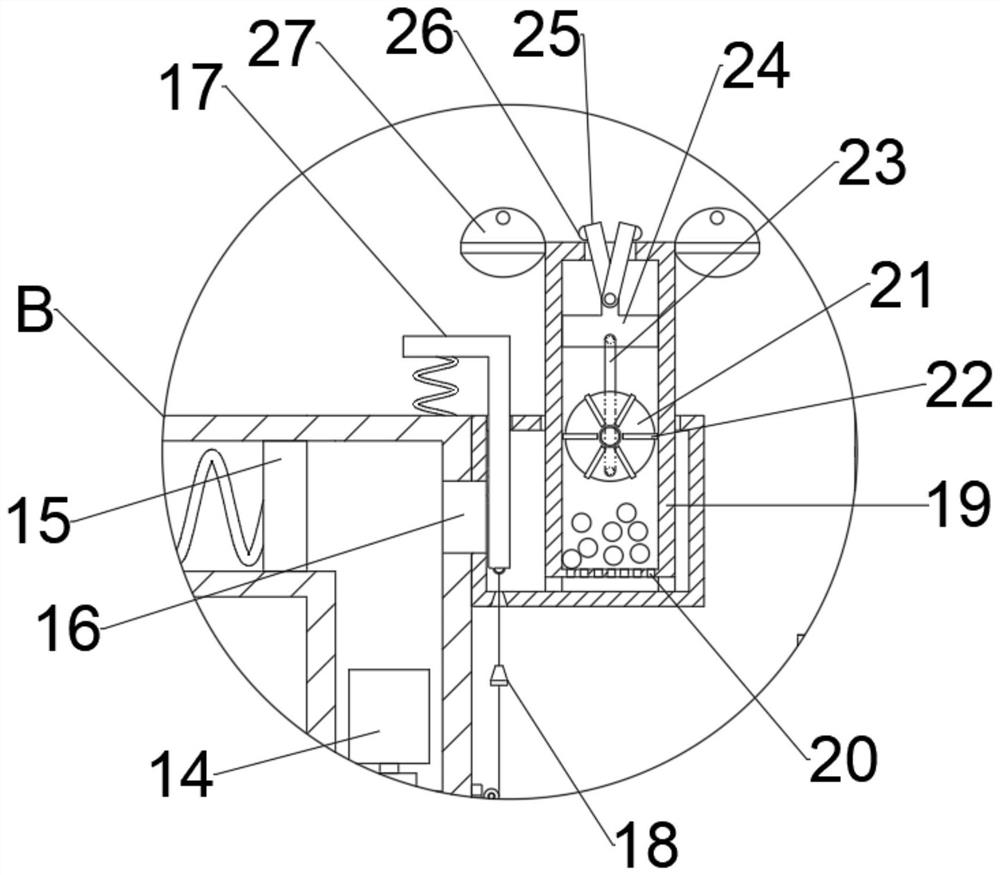

The invention discloses a gravity self-centering self-locking clamp. The gravity self-centering self-locking clamp is composed of a chassis, a bearing structure and two or more clamping units. Each clamping unit is composed of a clamping rod, a lifting rod, a clamping arm and a stand column. The stand columns and chassis are fixed. The clamping arms are fixed on the stand columns and can rotate along the stand columns. The clamping rods are fixed at the top ends of the clamping arms. The lifting rods are fixed at the bottom ends of the clamping arms. The bearing structure is composed of a spring and a carrier plate. The spring makes contact with the chassis. The carrier plate is fixedly connected with the lifting rod. The modular design is adopted, gravity and elastic force are combined through the lever principle, products are automatically clamped when being placed in the clamp and automatically loosened when being taken out from the clamp, and the clamp has the automatic centering effect and the self-locking effect.

Owner:徐旭东

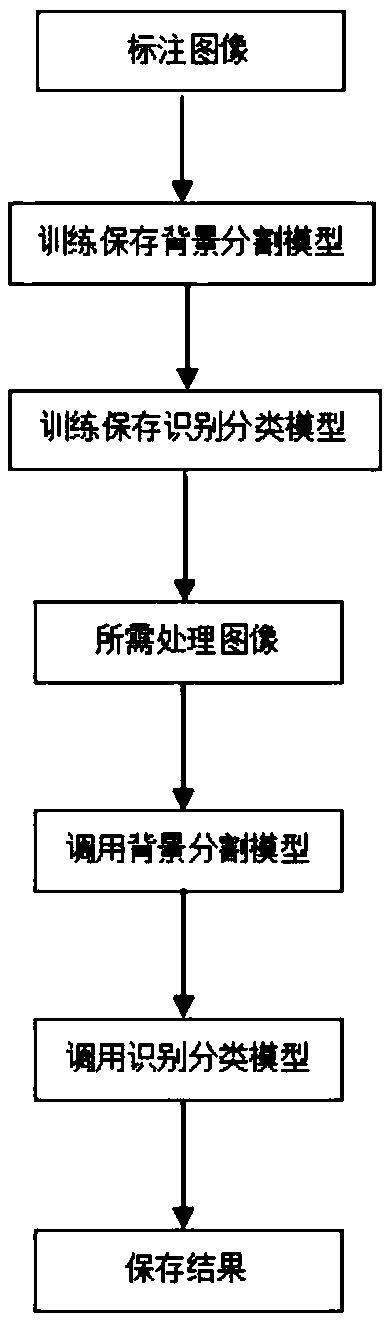

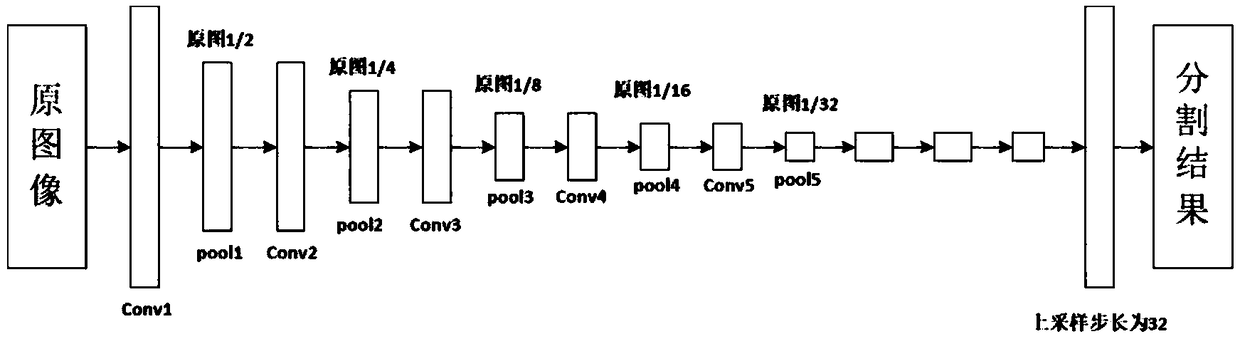

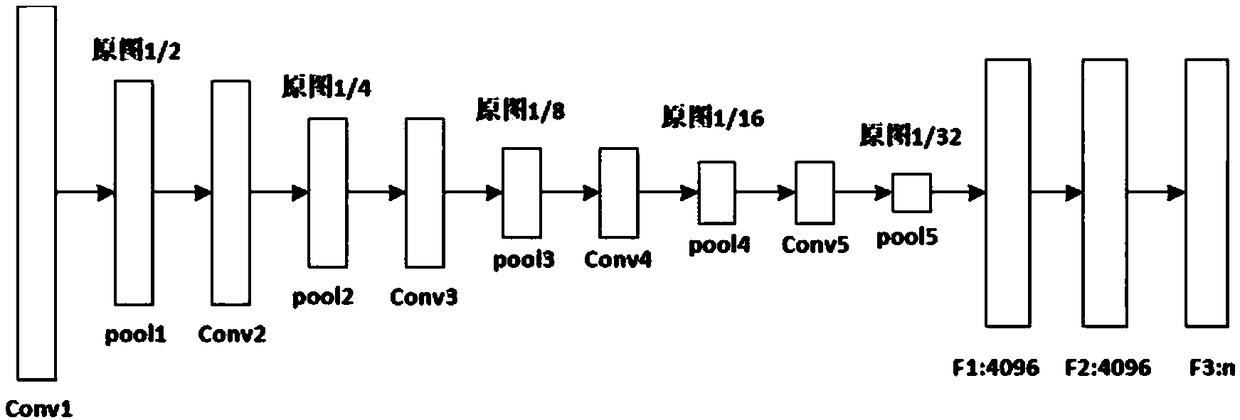

Image background segmentation and recognition method based on convolution neural network

ActiveCN108765449ARealize the effect of automationEfficient removalImage enhancementImage analysisNetwork modelSample image

The invention discloses an image background segmentation and recognition method based on a convolution neural network. The method uses the convolution neural network to learn a sample image, trains toobtain a background segmentation model and a recognition classification model, and then performs background segmentation and recognition classification of the image according to the model. When the convolution neural network is applied to the image recognition and classification, the invention combines the influence of the image background on the recognition and classification, and the backgroundsegmentation model converts the whole connection layer of the convolution neural network into the convolution layer. The invention improves the effect of image optimization segmentation, and makes the image background segmentation model have wide applicability. Finally, after the image background segmentation is realized by using the convolution neural network model, the image is reused for imagerecognition and classification, so as to improve the accuracy of recognition and classification.

Owner:NANJING UNIV OF INFORMATION SCI & TECH

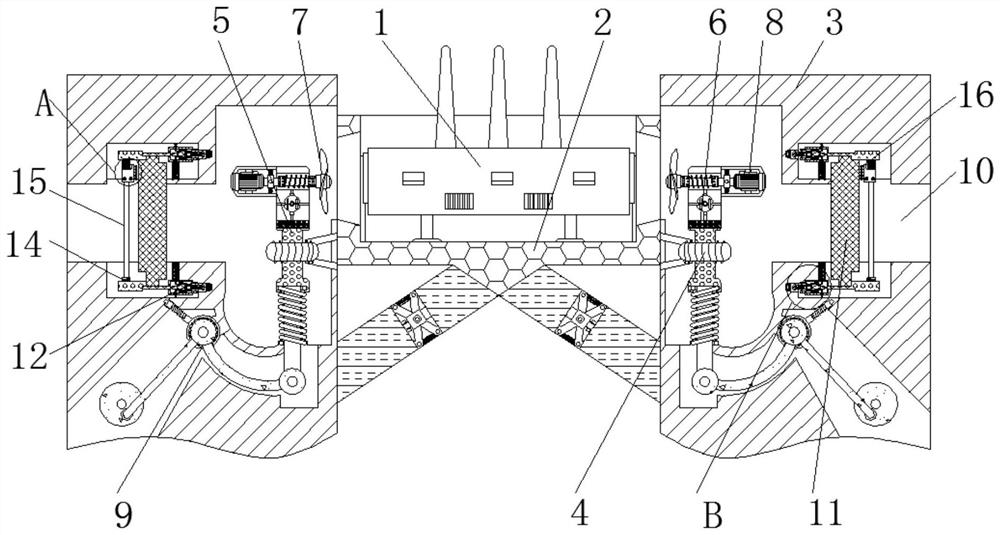

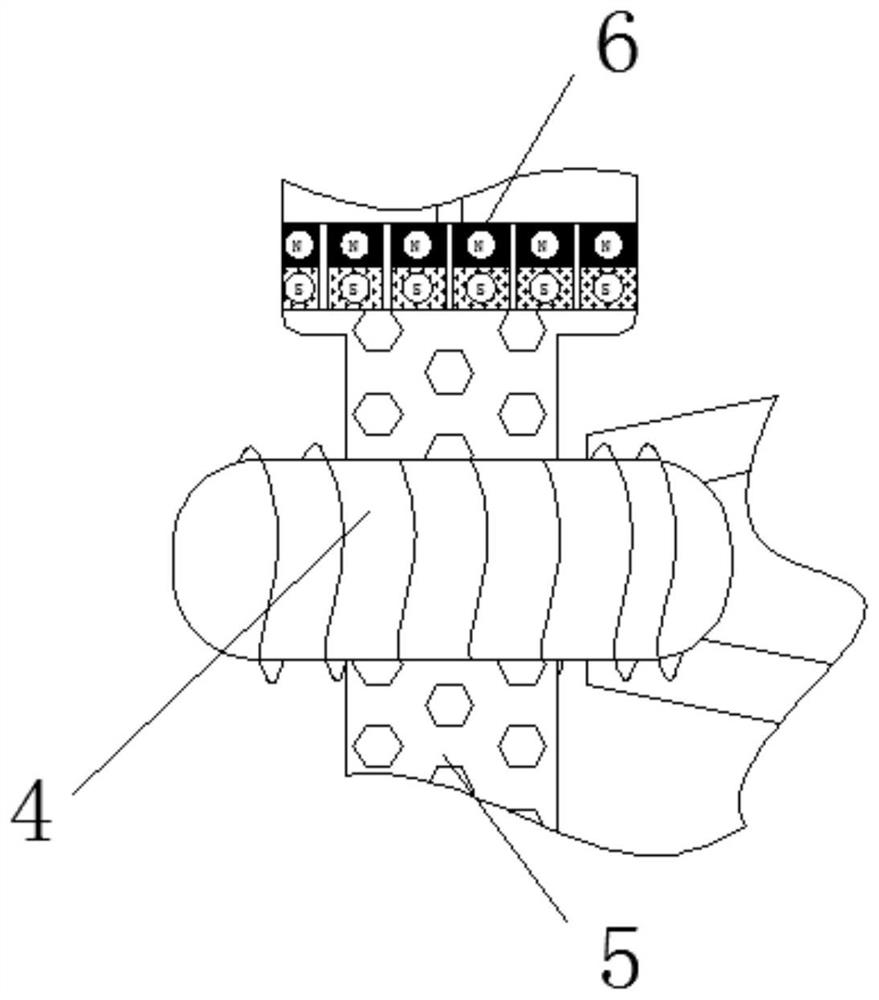

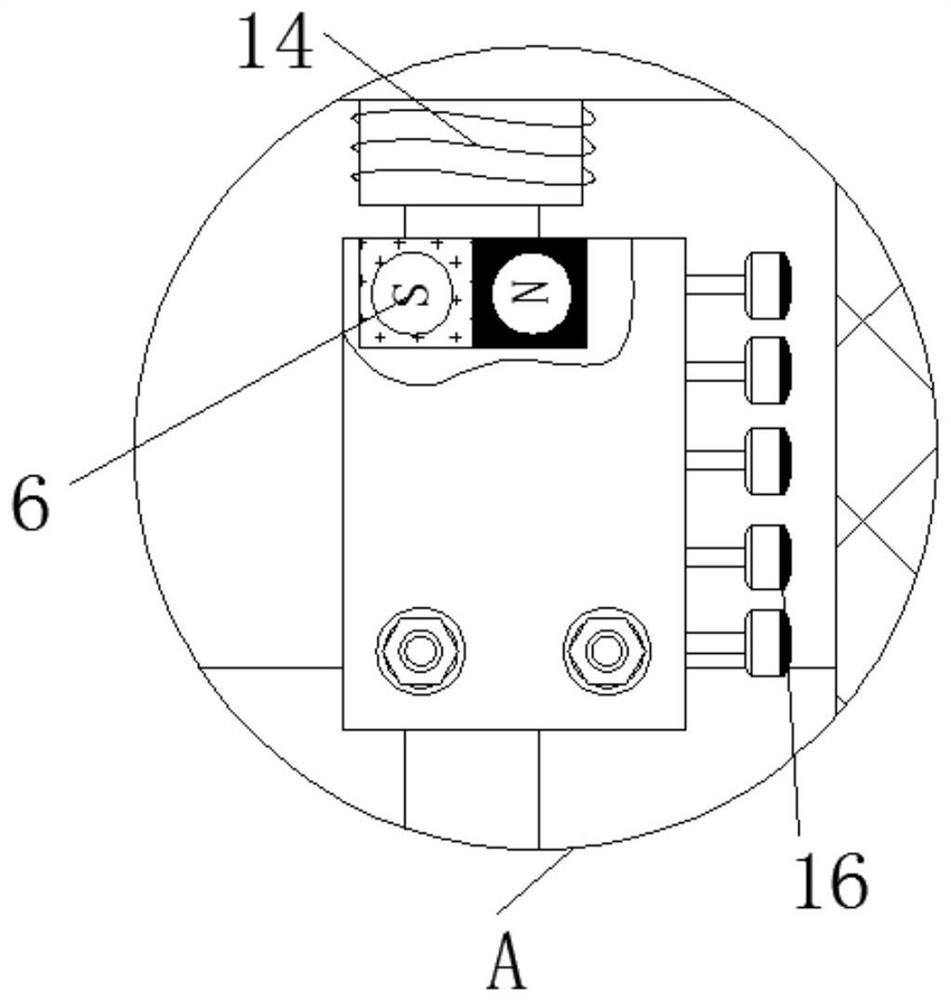

Router cooling device with automatic dust removal function

InactiveCN112468890AWith automatic dust removal functionFully cooledDispersed particle filtrationTransportation and packagingDust controlThe Internet

The invention relates to the technical field of the Internet, and discloses a router cooling device with an automatic dust removal function, which comprises a router, the outer part of the router is fixedly connected with a shell, the outer part of the shell is fixedly connected with a box body, and the inner part of the box body is fixedly connected with an annular coil; a supporting rod is movably sleeved with the annular coil, a permanent magnet is fixedly connected to the interior of the supporting rod, fan blades are movably connected to the upper end of the supporting rod, a reciprocating device is movably connected to the lower end of the supporting rod, an air inlet is formed in the box body, and a filter screen is movably connected to the interior of the air inlet; and a trigger device is movably connected to the upper end of the filter screen, an electromagnet is fixedly connected to the right end of the trigger device, a sliding rod is sleeved with the electromagnet, and a brush head is sleeved with the sliding rod. The device has the advantages that the temperature of the router can be reduced, and dust absorbed by the fan can be automatically removed.

Owner:广州云宁实业有限公司

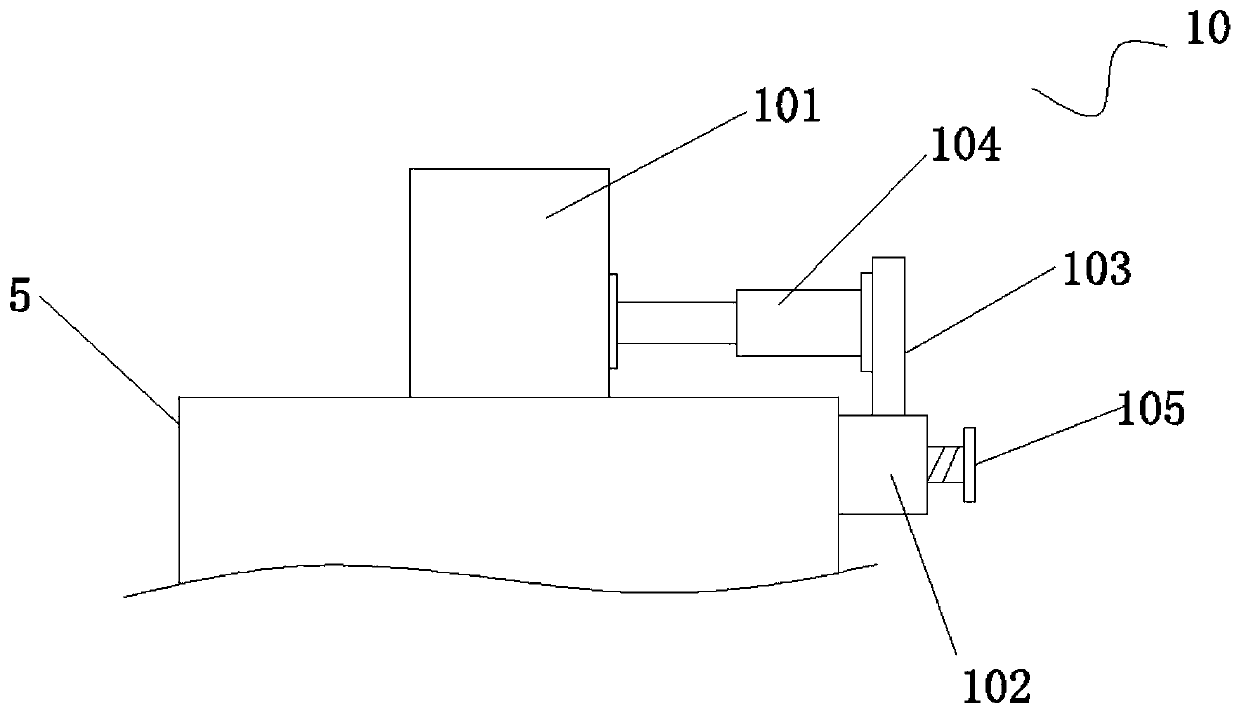

New device for punching new materials

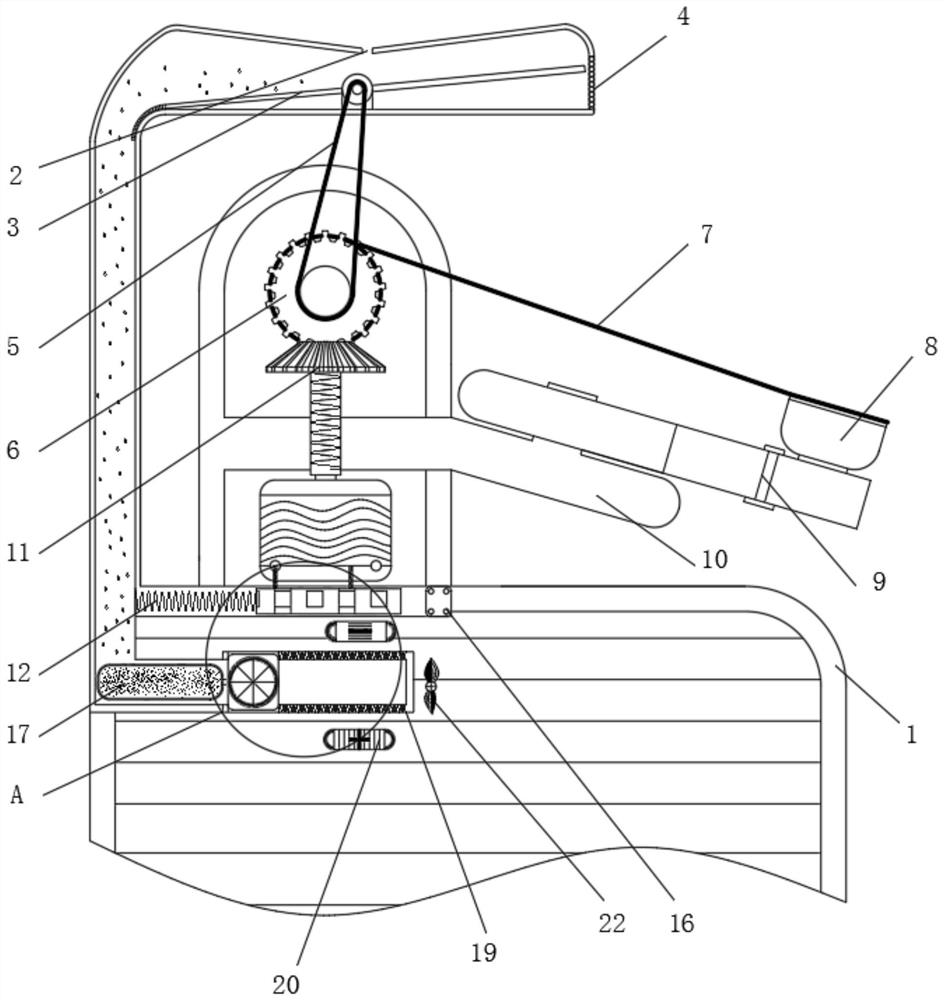

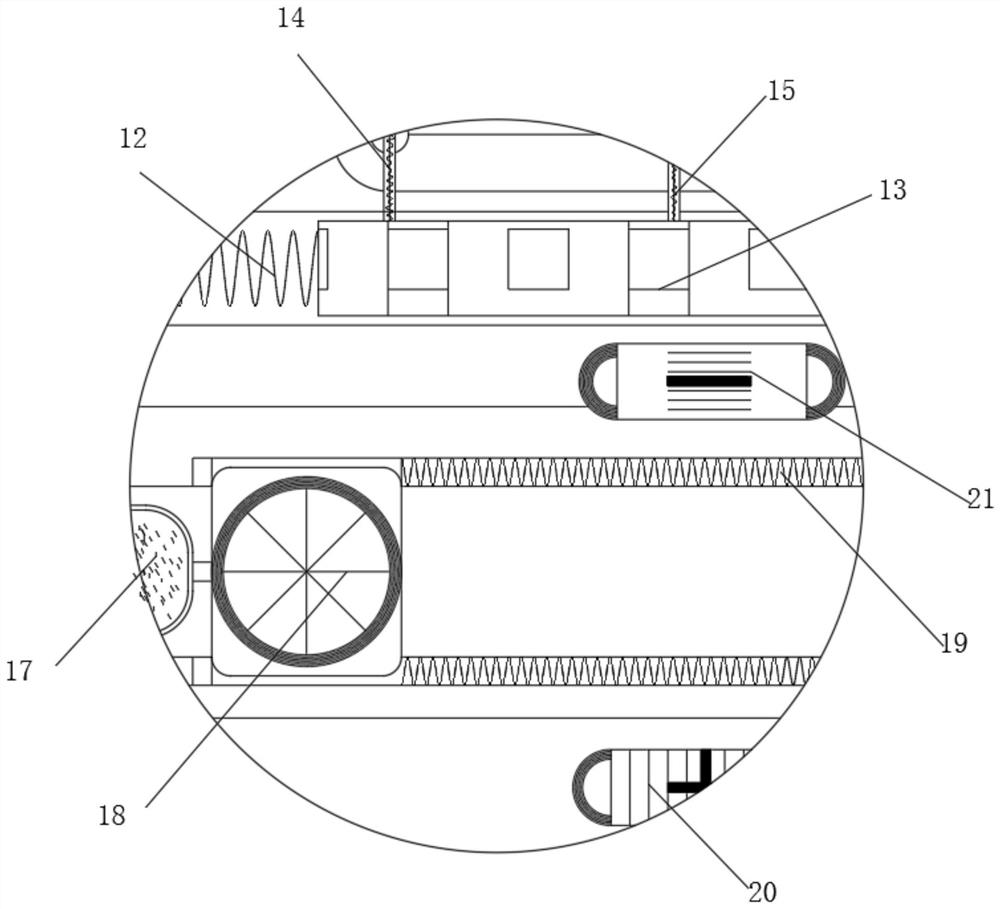

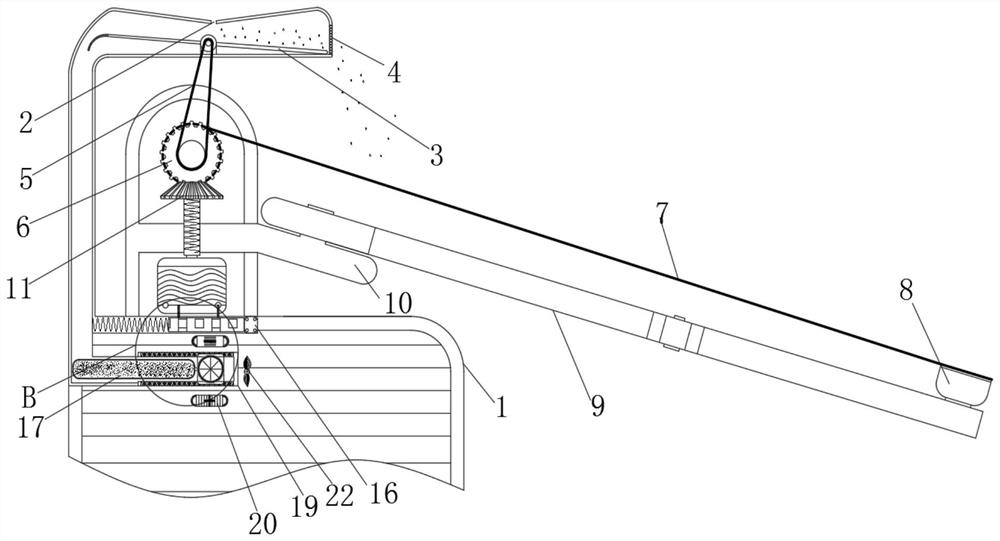

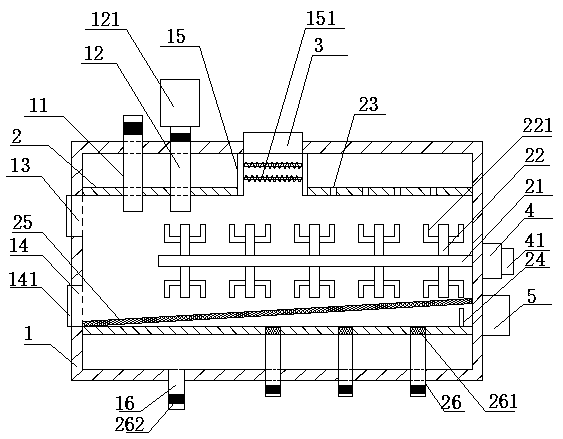

ActiveCN109079519ARealize the effect of automationTo achieve the effect of saving time and effortOther manufacturing equipments/toolsMaintainance and safety accessoriesPunchingEngineering

The invention discloses a new device for punching a new material, which comprises a workbench and a first motor. The second rotary is connected with a second support plate in socket mode, and the second support plate is fixedly connected with the workbench; the bottom of the conveyor belt is connected with a new material, and the outer of the new material is connected with a locating frame. By adding the first motor and a second motor, the first motor can achieve the effect of automation, and the second motor can achieve the up-and-down movement of a bit. As the bit moves up and down, there isno need to change the height of the bit, thereby saving both time and labour. By adding a grindstone, the grindstone can contact the hole wall and grind the hole wall after the bit completes the punching and continues to move down, accordingly punching and grinding can be achieved at one time.

Owner:SUZHOU RUIPENGCHENG SCI & TECH CO LTD

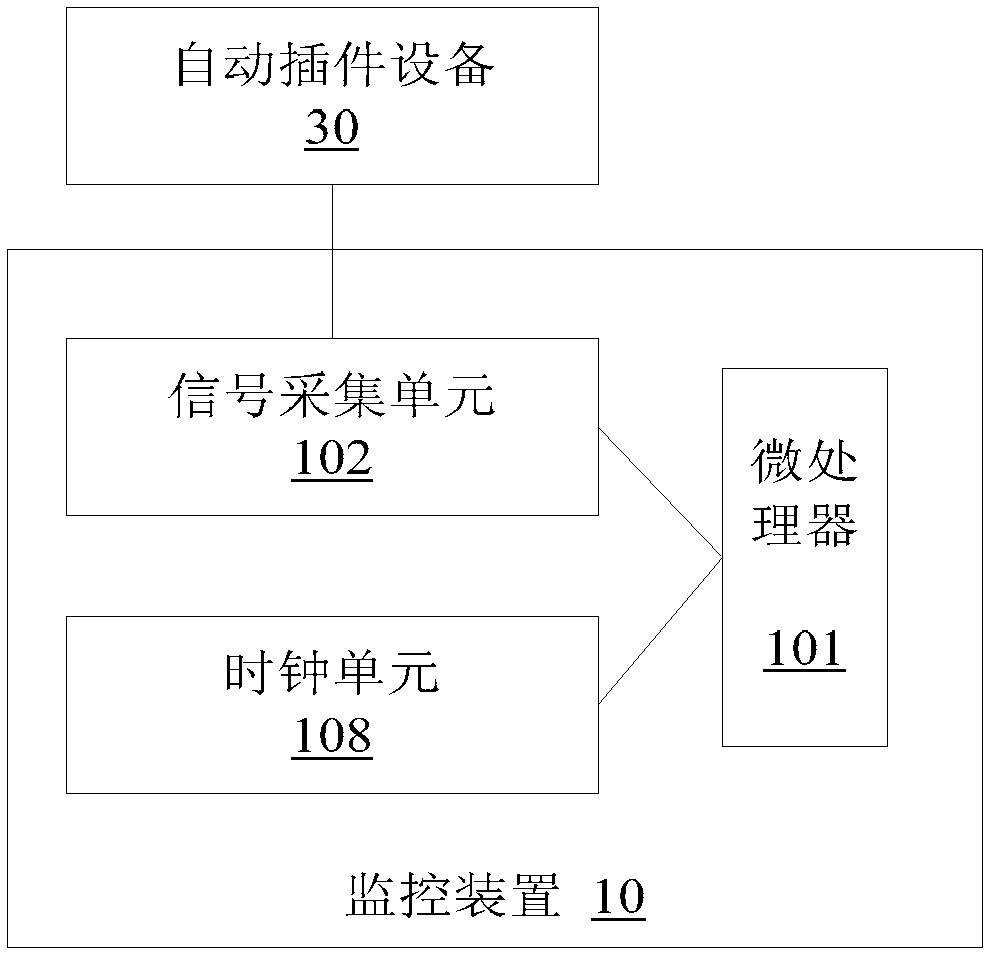

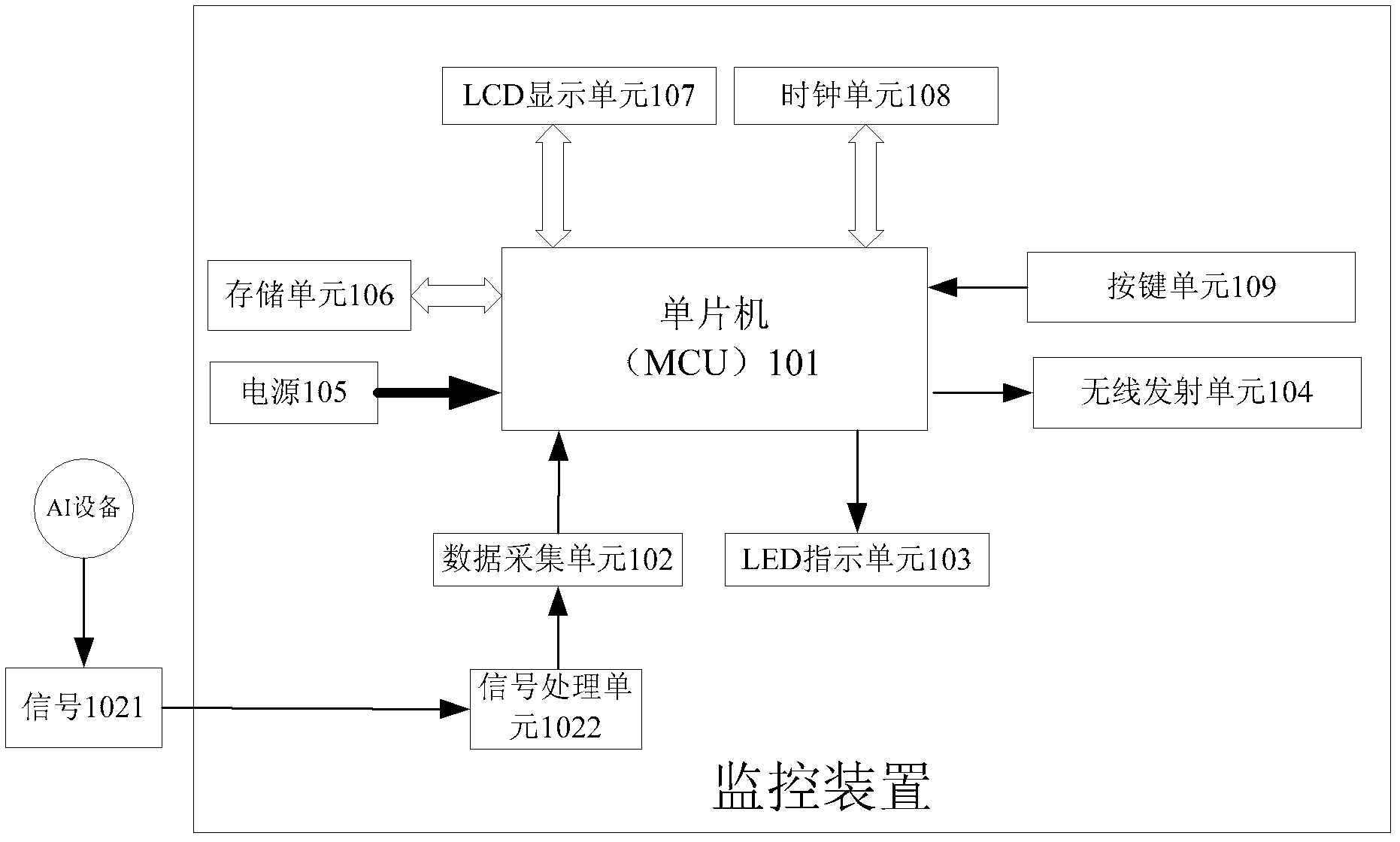

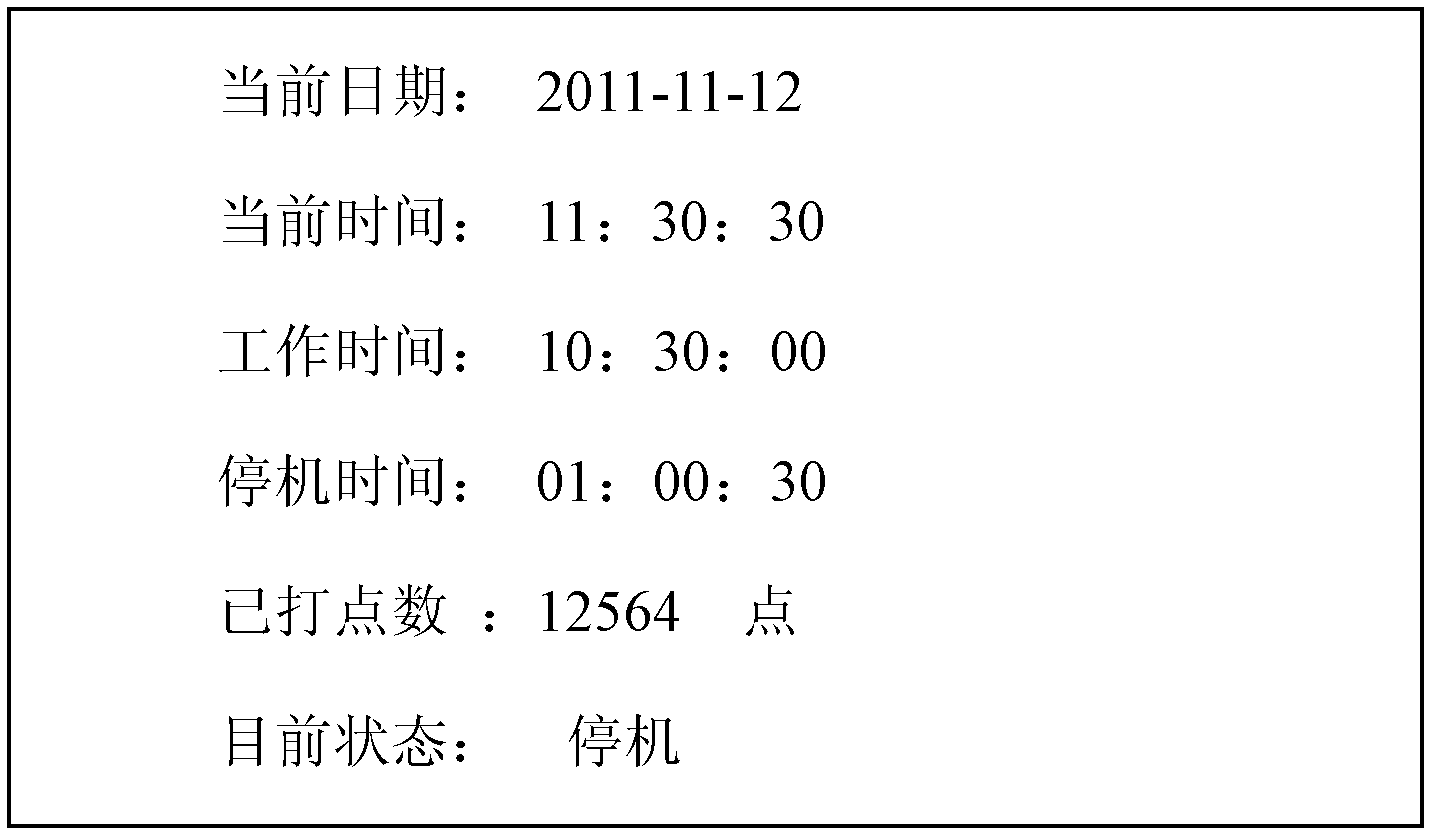

Monitoring device of automatic plug-in device, monitoring method and monitoring system

ActiveCN103150781AResolve accuracySolve resource problemsRegistering/indicating working of machinesTime informationMonitoring system

The invention discloses a monitoring device of an automatic plug-in device, a monitoring method and a monitoring system. The monitoring device of the automatic plug-in device comprises 1, a signal acquisition unit which is connected to the automatic plug-in device and is used for acquisition of signals output by the automatic plug-in device, wherein in the automatic plug-in operation, the automatic plug-in device outputs a first signal, and when the operation is stopped, the automatic plug-in device outputs a second signal, and the first signal is different from the second signal; 2, a clock unit which is used for producing time information; and 3, a microprocessor which is connected to the signal acquisition unit and the clock unit and is used for outputting stopping time information of the automatic plug-in device according to the time information produced by the clock unit when the automatic plug-in device outputs the second signal. The monitoring device can automatically monitor and acquire stopping time of the automatic plug-in device, and saves manpower resource.

Owner:GREE ELECTRIC APPLIANCES INC

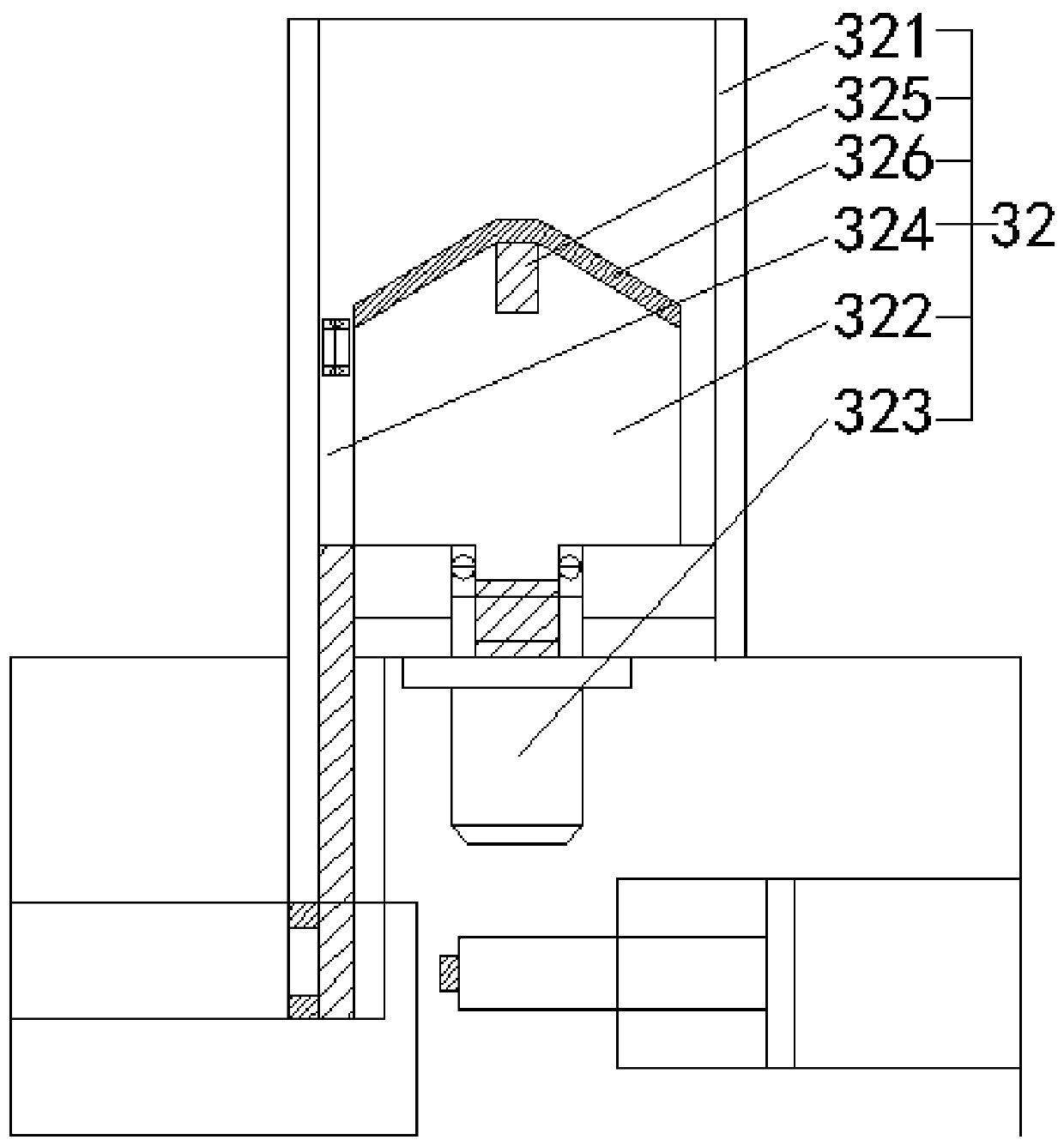

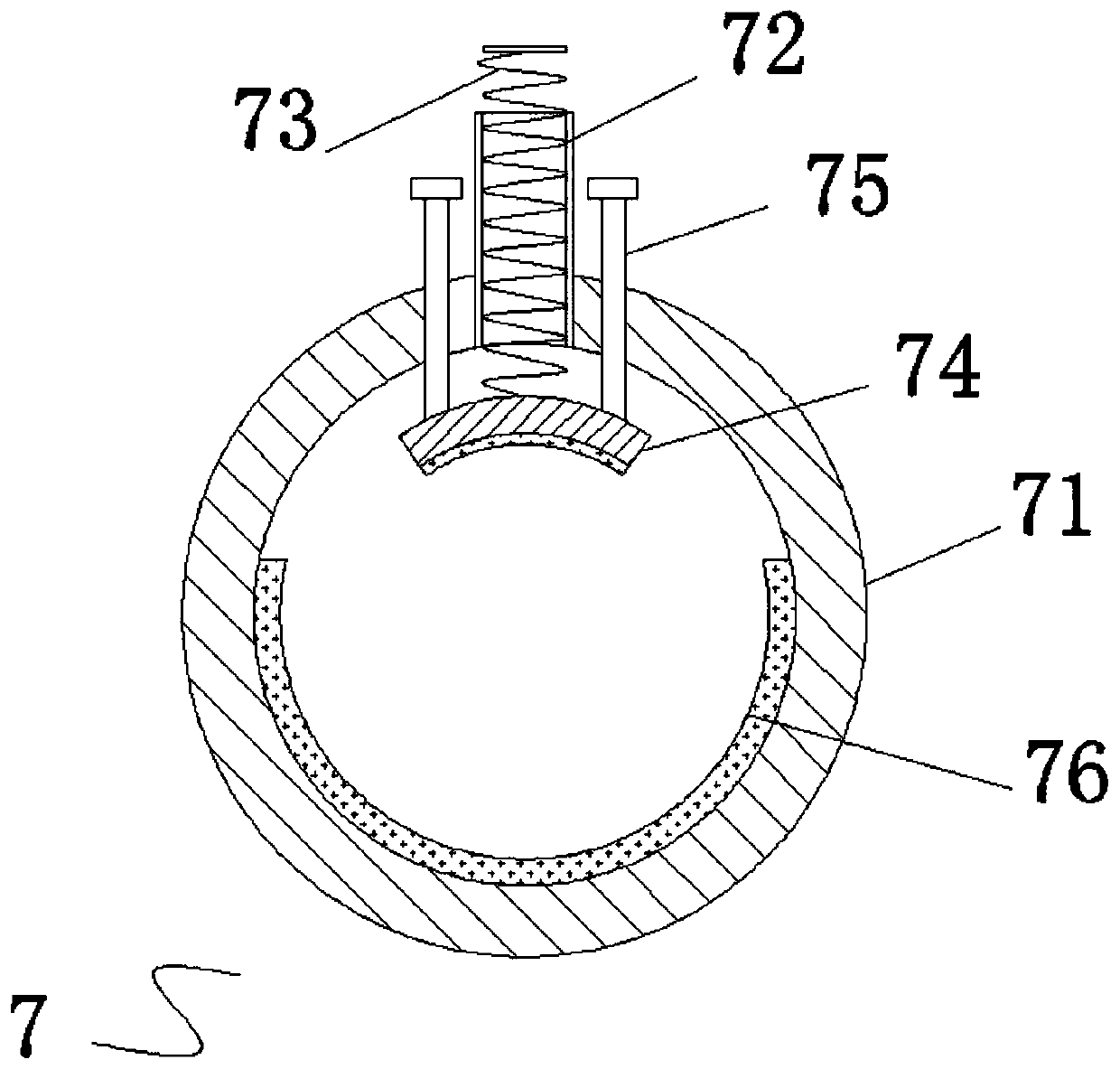

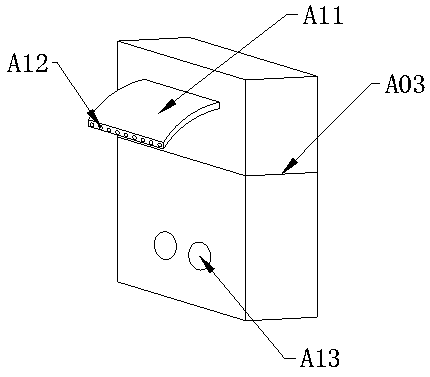

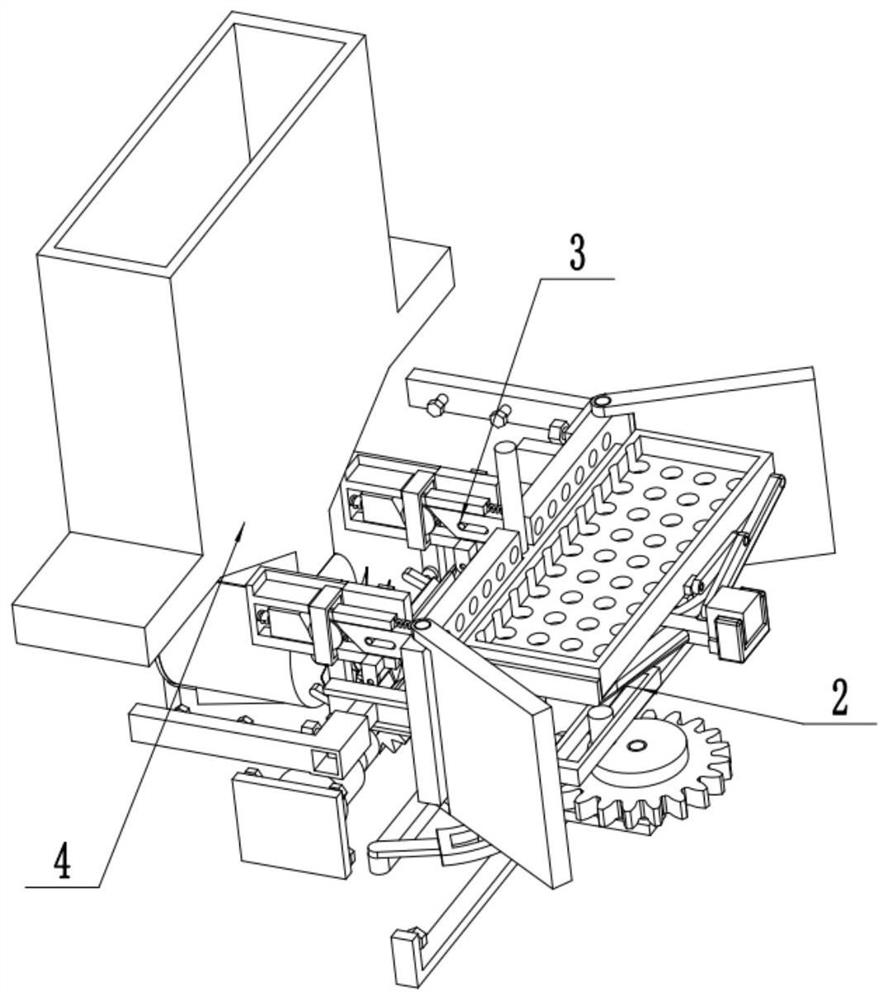

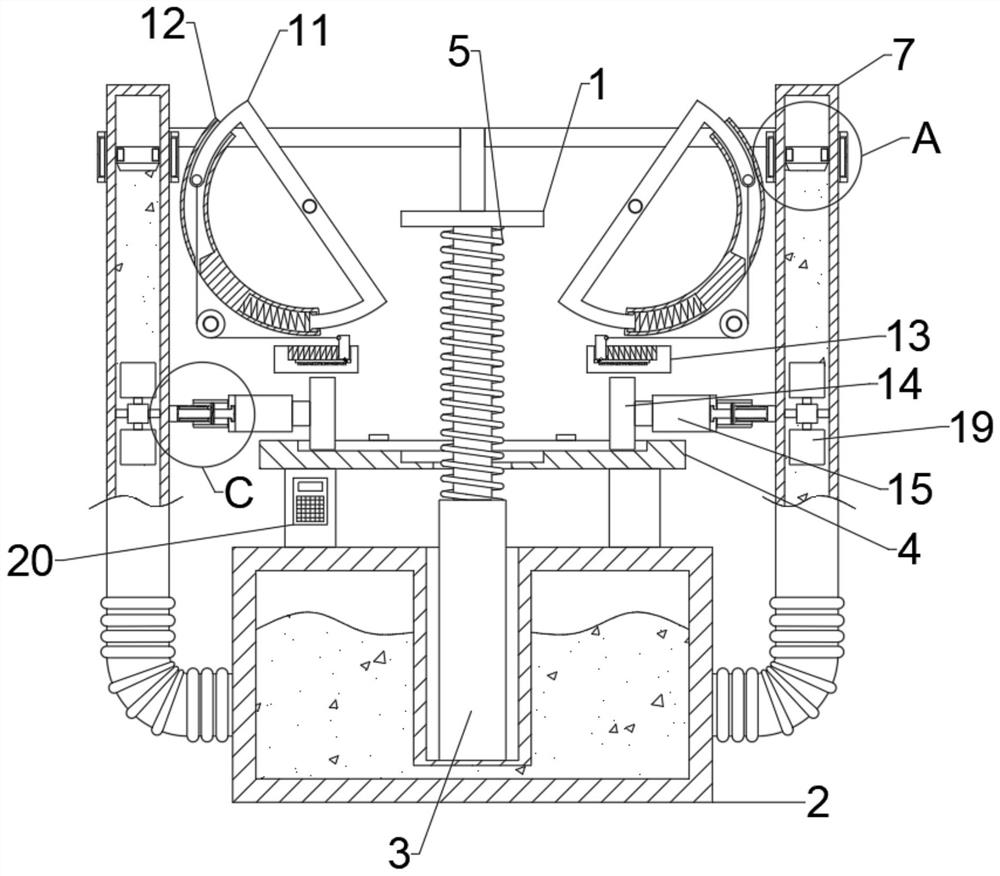

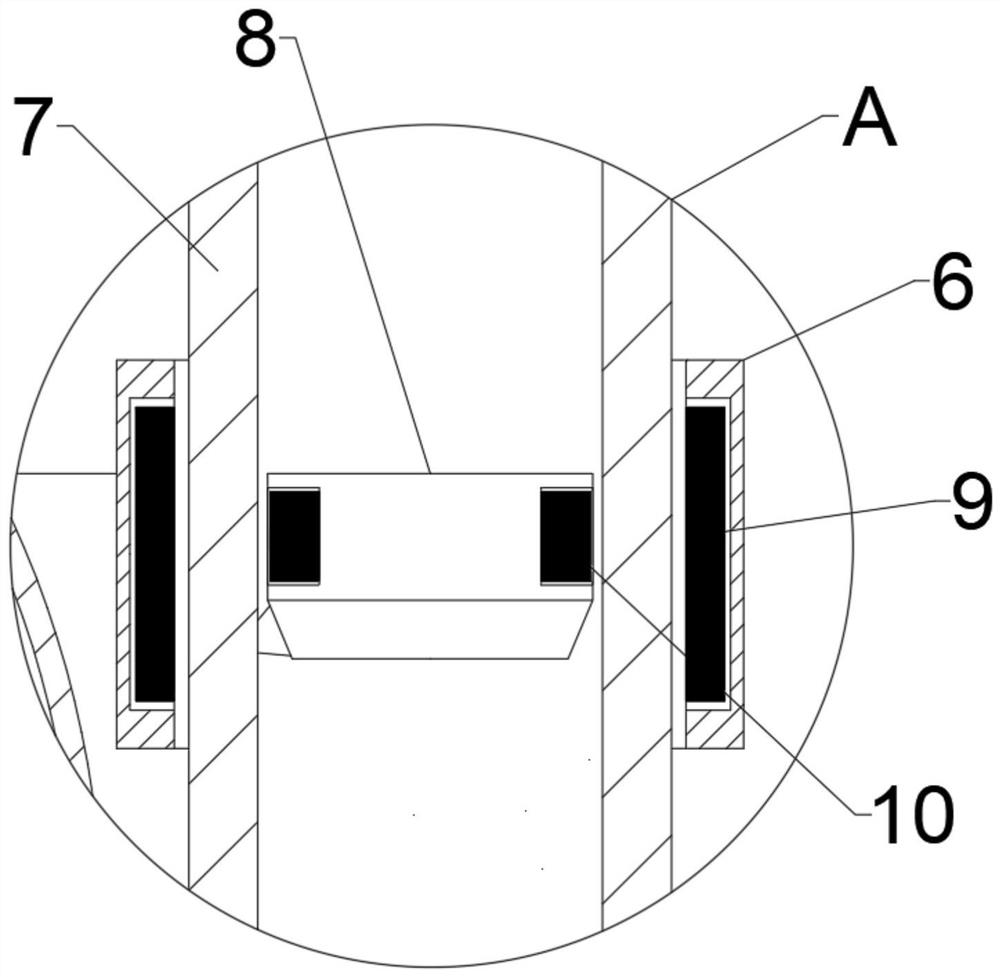

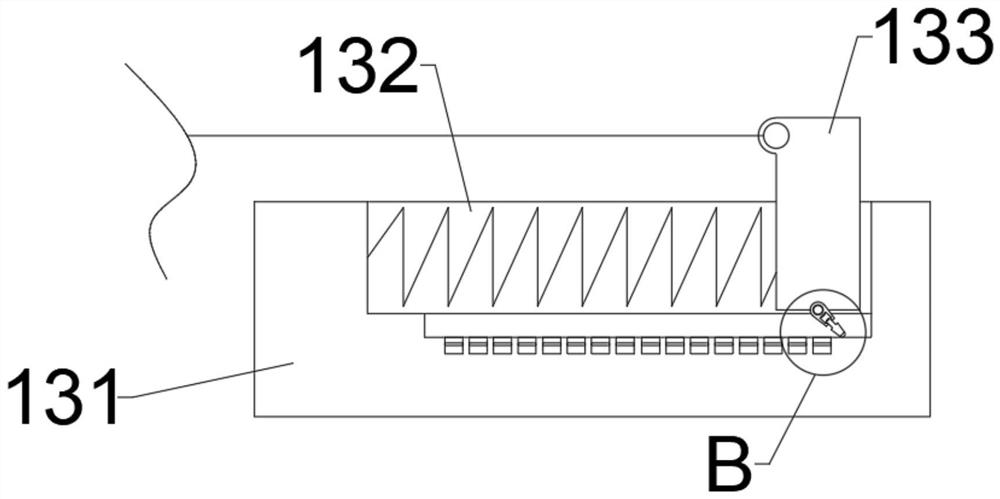

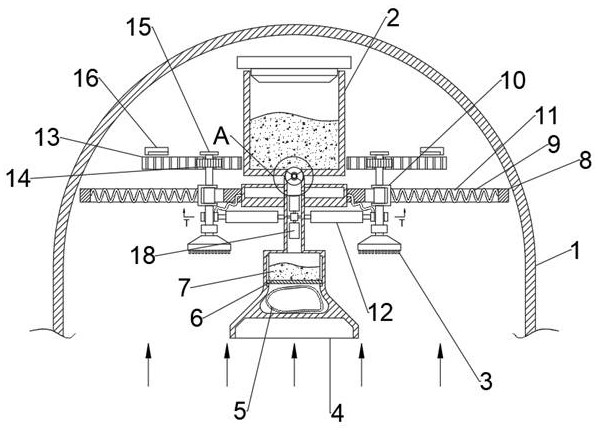

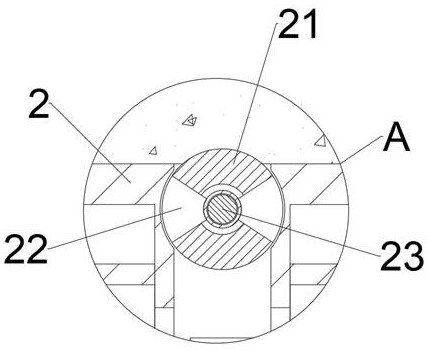

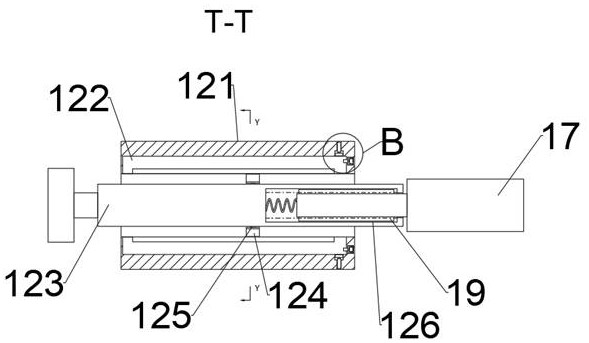

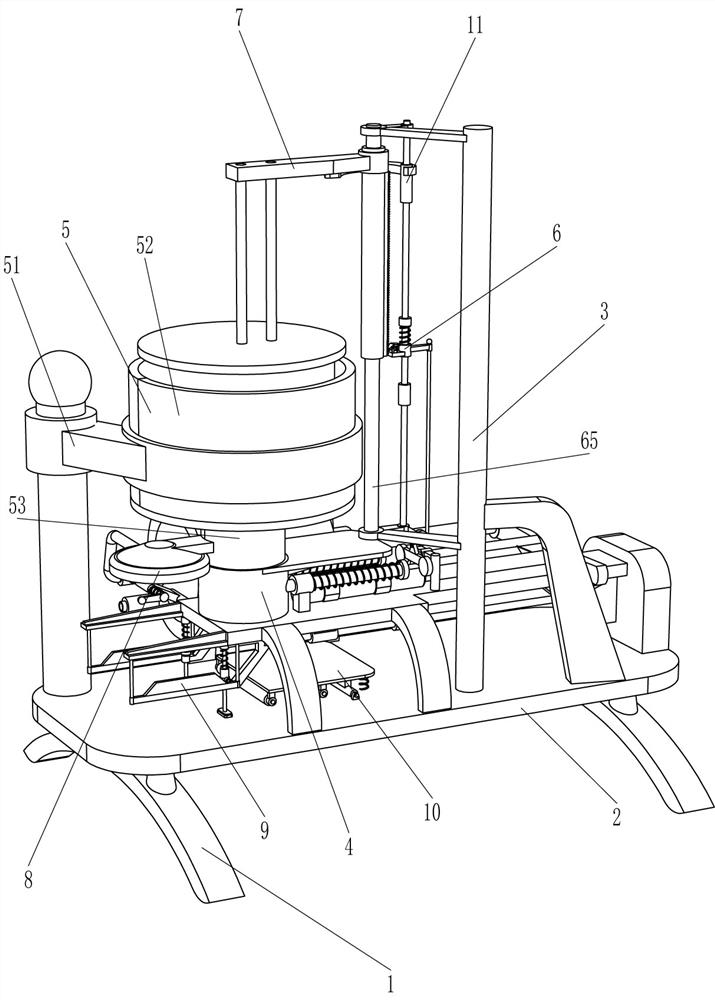

Deep groove ball bearing outer ring inner roller way machining device and method

PendingCN110193768AHigh degree of automationIncrease productivityGrinding carriagesAbrasive surface conditioning devicesBall bearingMachining

The invention relates to the technical field of grinding, in particular to a deep groove ball bearing outer ring inner roller way machining device and method. According to the technical scheme, the deep groove ball bearing outer ring inner roller way machining device comprises a machine frame, a rough machining device arranged on the machine frame, a finish machining device and a conveying mechanism for conveying roughly finished products into the finish machining device; the rough machining device comprises an input device mounted on the machine frame, a rough grinding portion, and an outputtable; and the finish machining device comprises a machining bin, a charging device mounted at the top of the machining bin, a rough grinding portion arranged on the part, in an inner cavity of the machining bin, of the machine frame, and a conveying belt arranged on the part, outside the machining bin, of the machine frame. The machining device and method is high in practicability and novelty andeasy to popularize.

Owner:浙江安贝实业有限公司

Automatic spraying device

InactiveCN109433476AFull Spray OperationEfficient sprayingSpraying apparatusRotary stageElectric machinery

Owner:黄钟葳

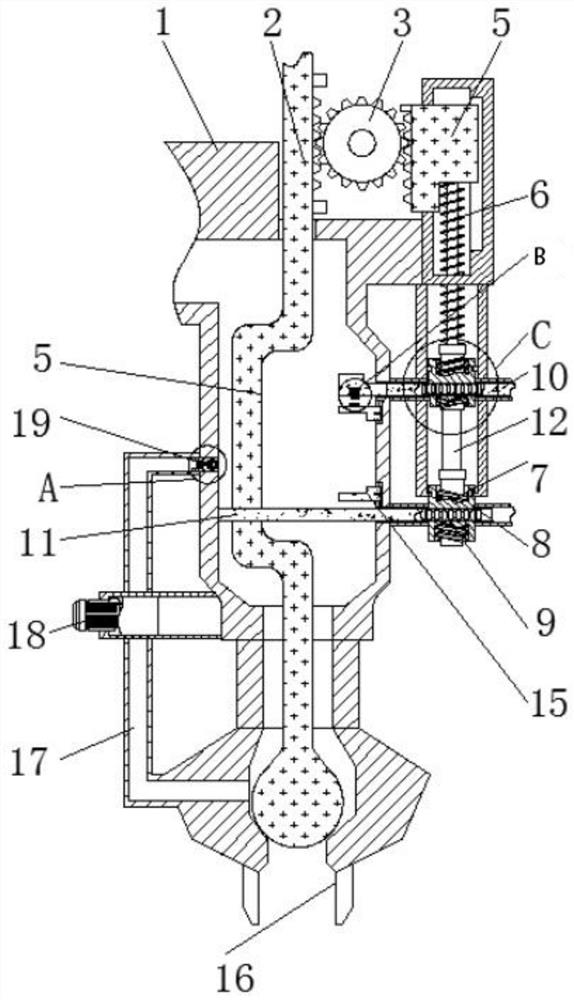

Charging pile with automatically telescopic canopy device

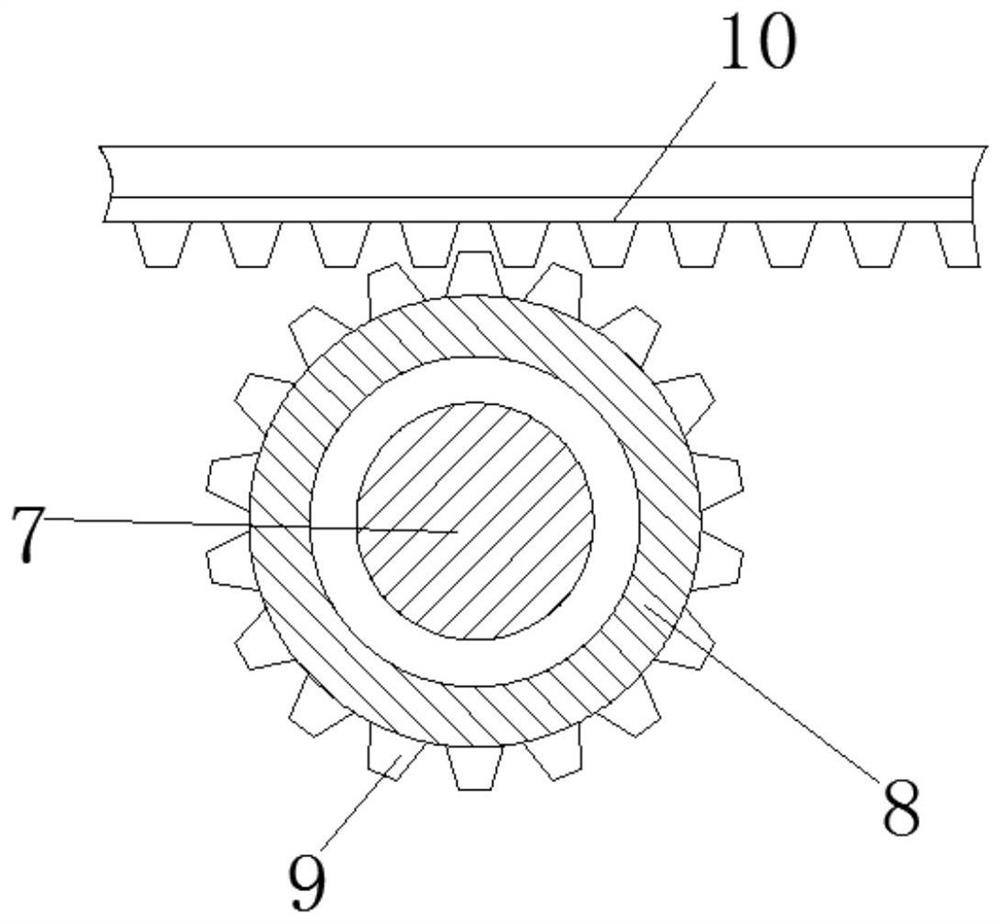

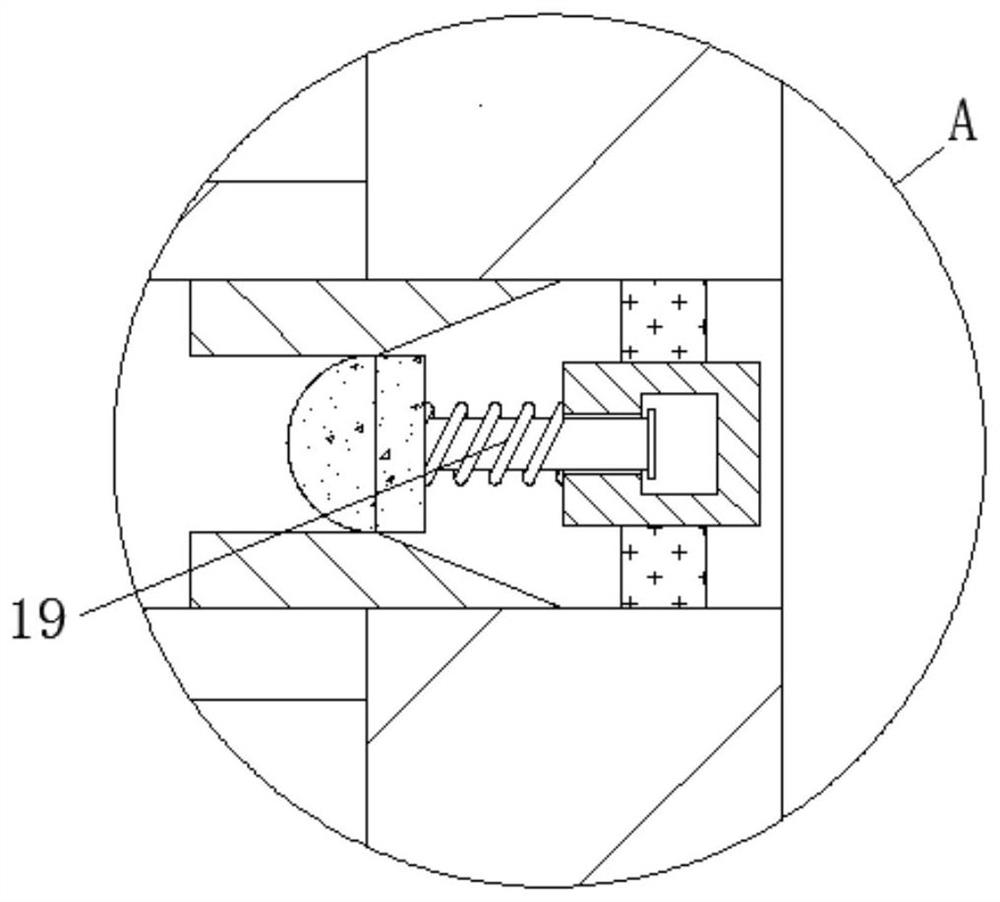

InactiveCN112793451AEffectively expandRealize the effect of sheltering from rainSunshadesCharging stationsTransmission beltGear wheel

The invention relates to the technical field of electric power, and discloses a charging pile with an automatically telescopic canopy device, the charging pile comprises a shell, the top of the charging pile shell is provided with a water collecting port, and a lever water guide plate is fixedly connected to the inner part of the shell and close to the bottom of the water collecting port; a water outlet is formed in the outer wall of the shell and close to the right side of the lever water guide plate, the middle of the lever water guide plate is movably connected with one end of a transmission belt, the other end of the transmission belt is movably connected with a main gear, and the back face of the main gear is fixedly connected with one end of rain shielding cloth. According to the charging pile with the automatically telescopic canopy device, a servo motor drives a transmission gear rod to rotate, the transmission gear rod drives a main gear to rotate, the main gear rotates to enable a rainproof cloth to extend, a folding rod extends outwards under the action of gravity, and the rainproof cloth is used in cooperation with a fixing plate, so that the purpose of effectively unfolding the rainproof cloth is achieved; and the rain shielding effect is achieved.

Owner:广州零尚电商贸易有限公司

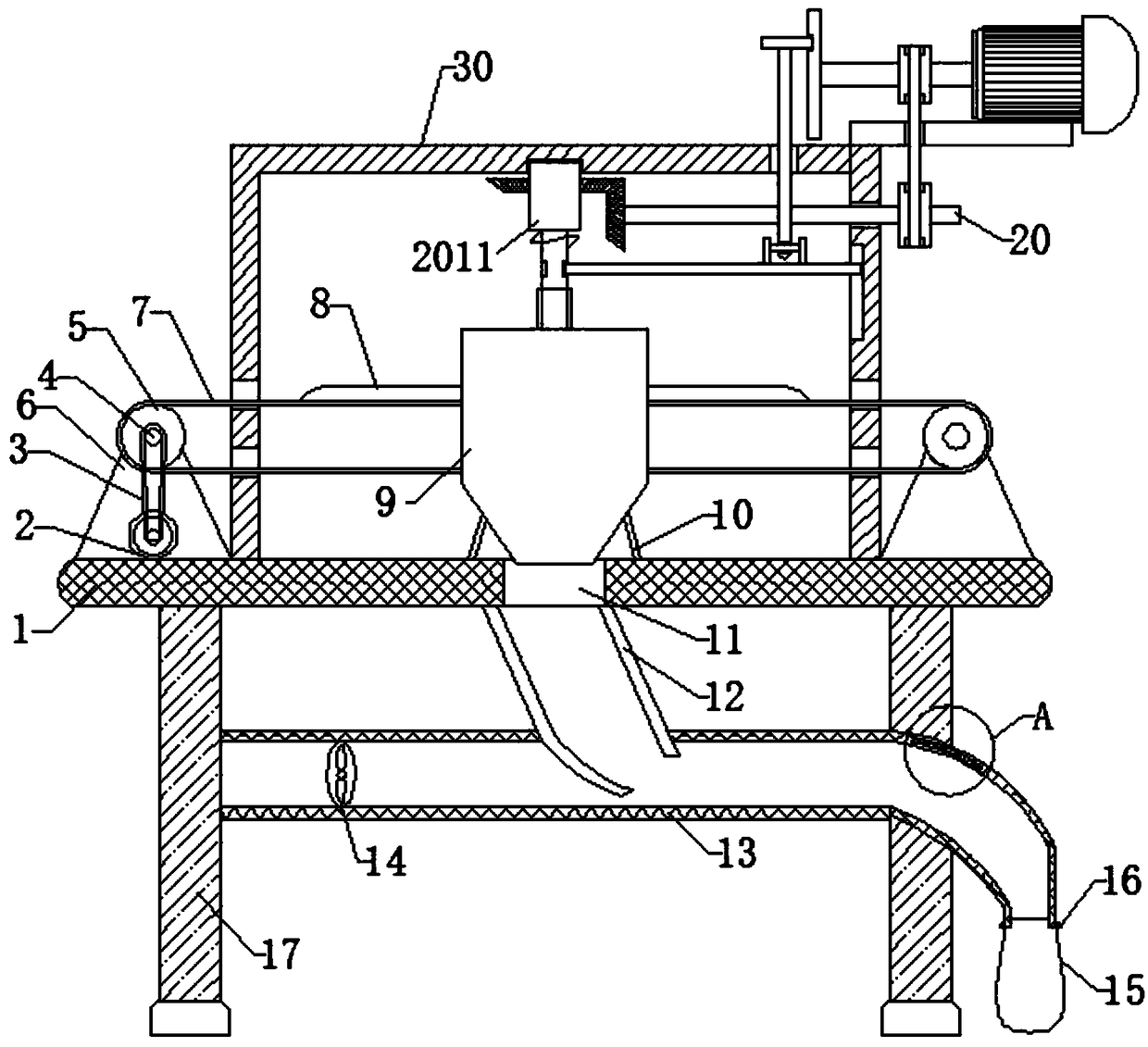

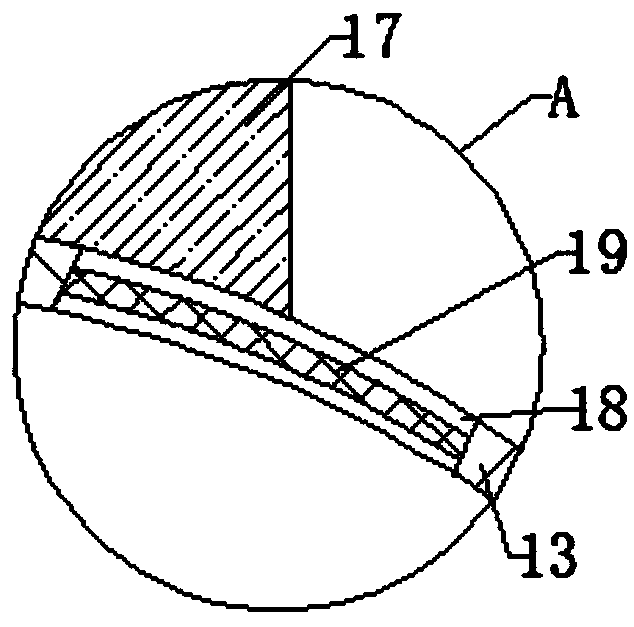

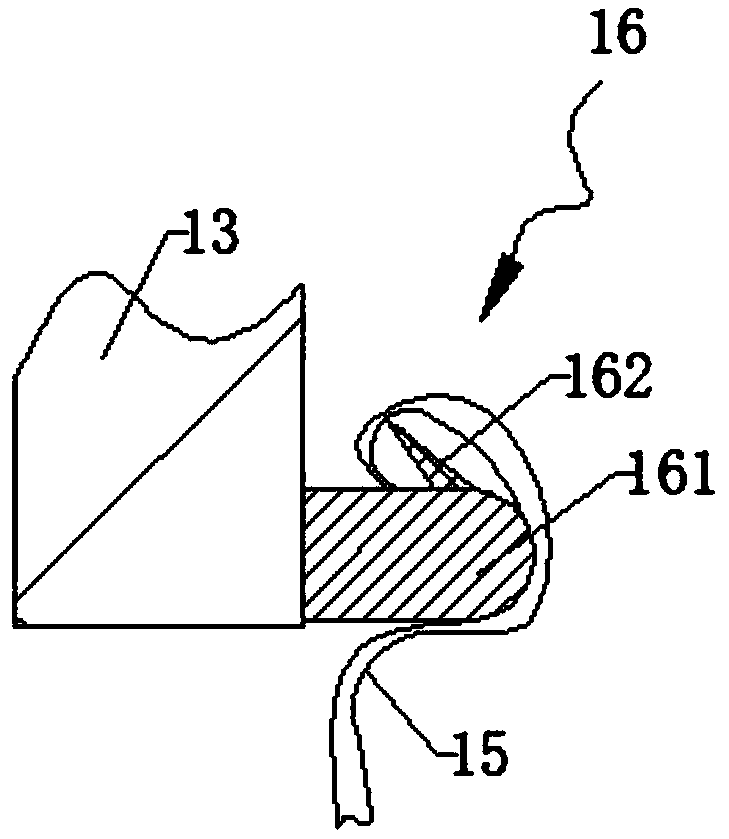

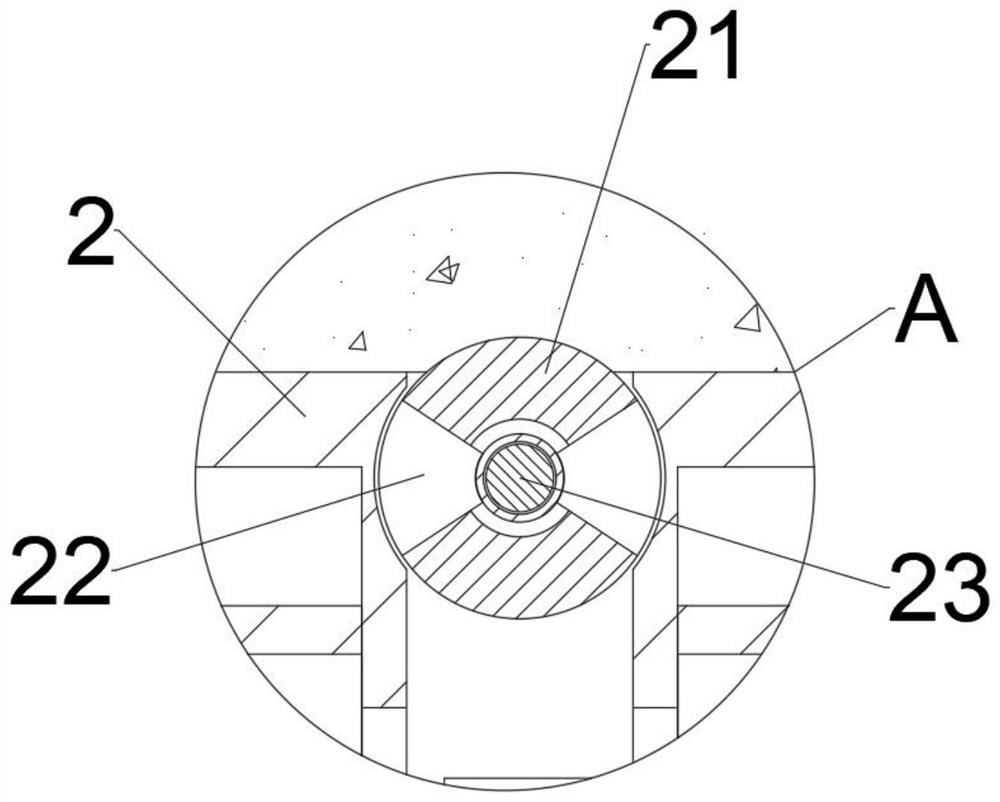

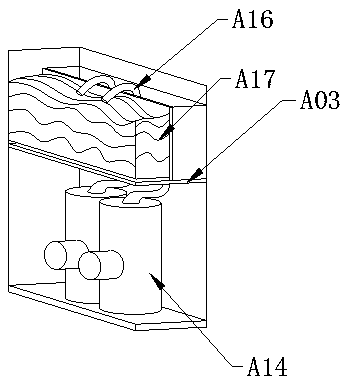

Attapulgite purifying device

The invention discloses an attapulgite purifying device, and relates to the technical field of attapulgite processing. The device comprises an outer barrel and an inner barrel arranged in the outer barrel. The outer barrel and the inner barrel share a same axial lead and both have a horizontally arranged cylindrical structure. The inner barrel has a front opening and a rear opening. The front opening and the rear opening are fixedly connected to the internal wall of the outer barrel. The device can purify attapulgite, is applied to the primary processing of attapulgite, is convenient to use, is simple to operate, and is very practical and flexible.

Owner:MINGGUANG FEIZHOU NEW MATERIAL

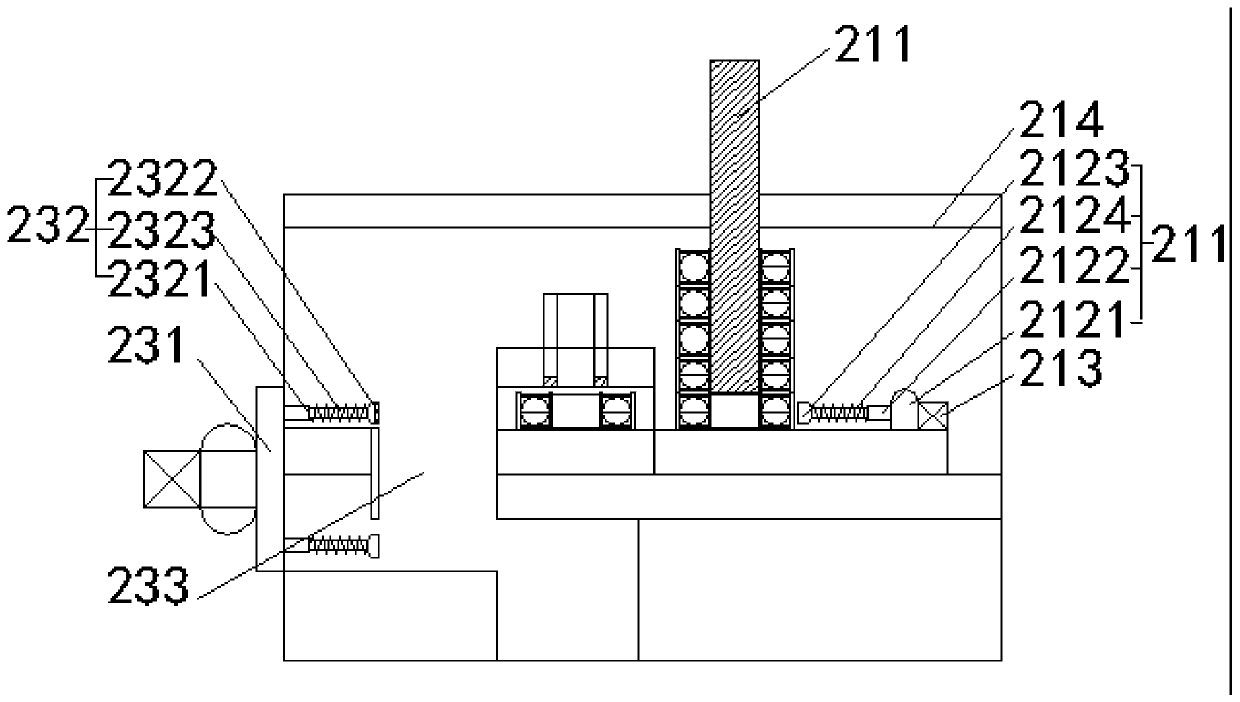

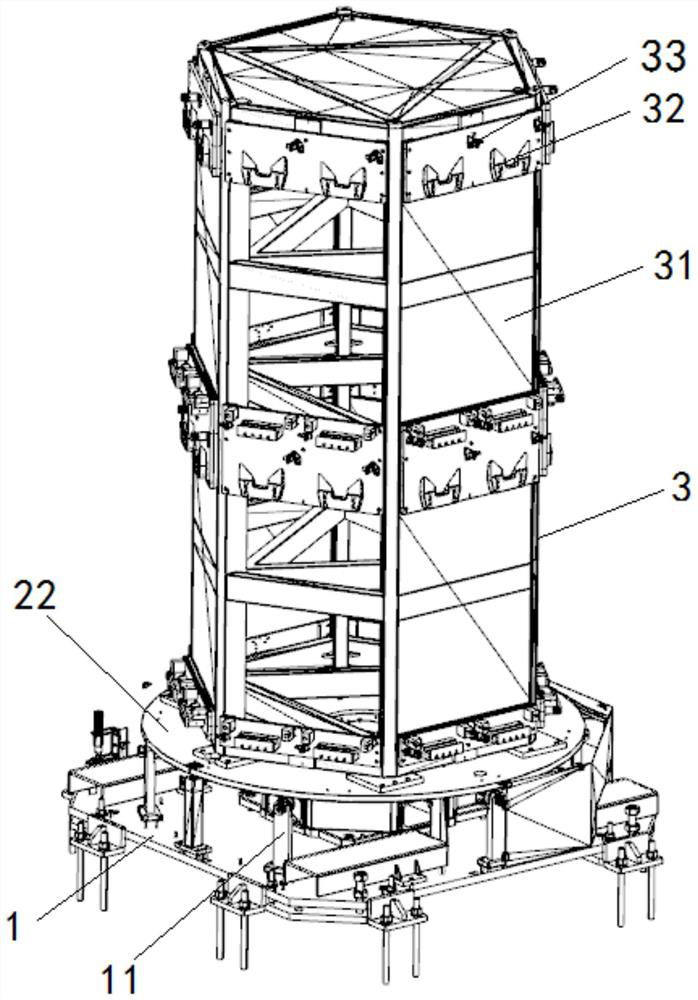

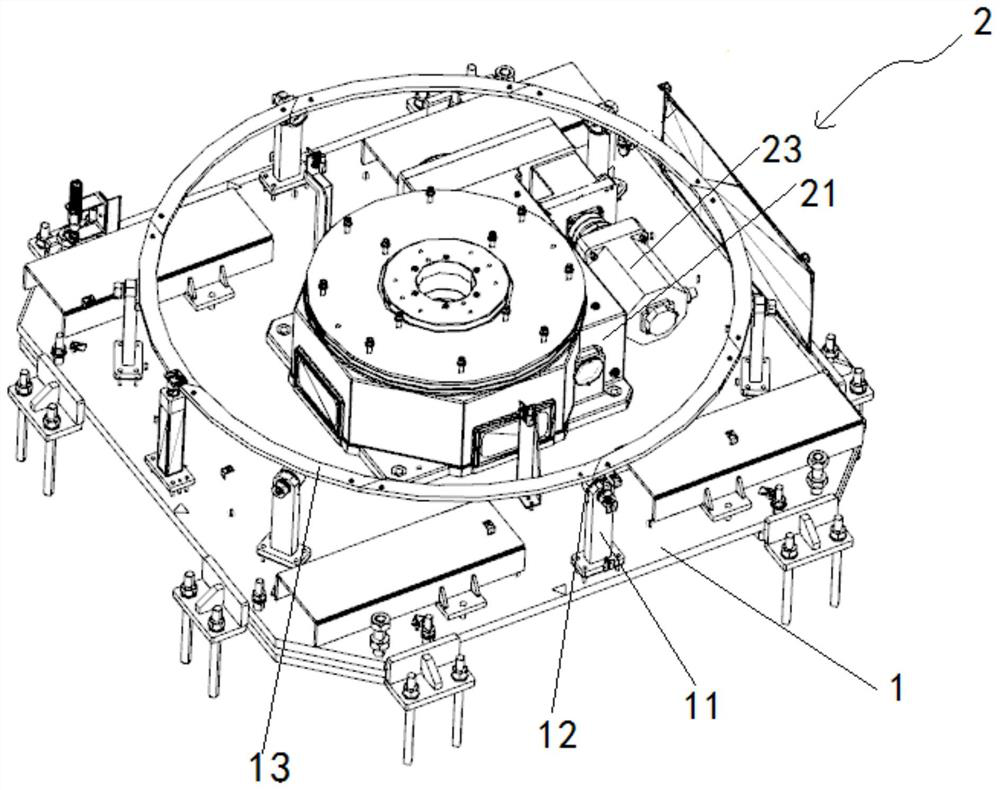

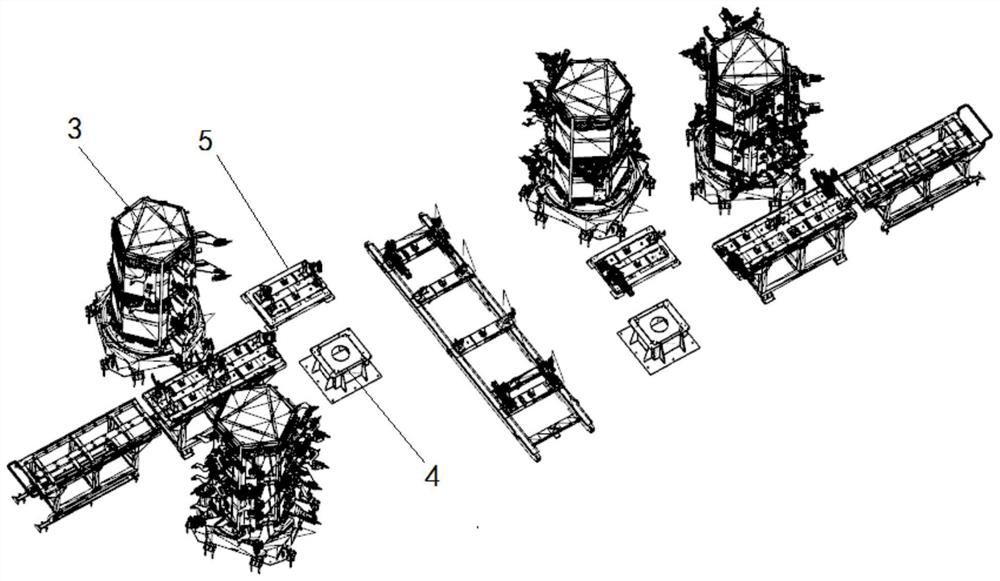

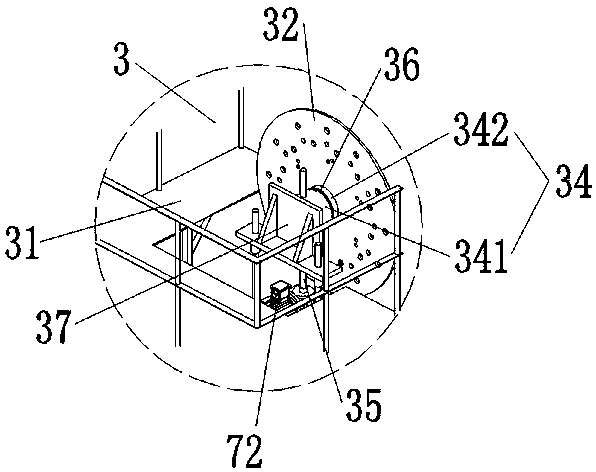

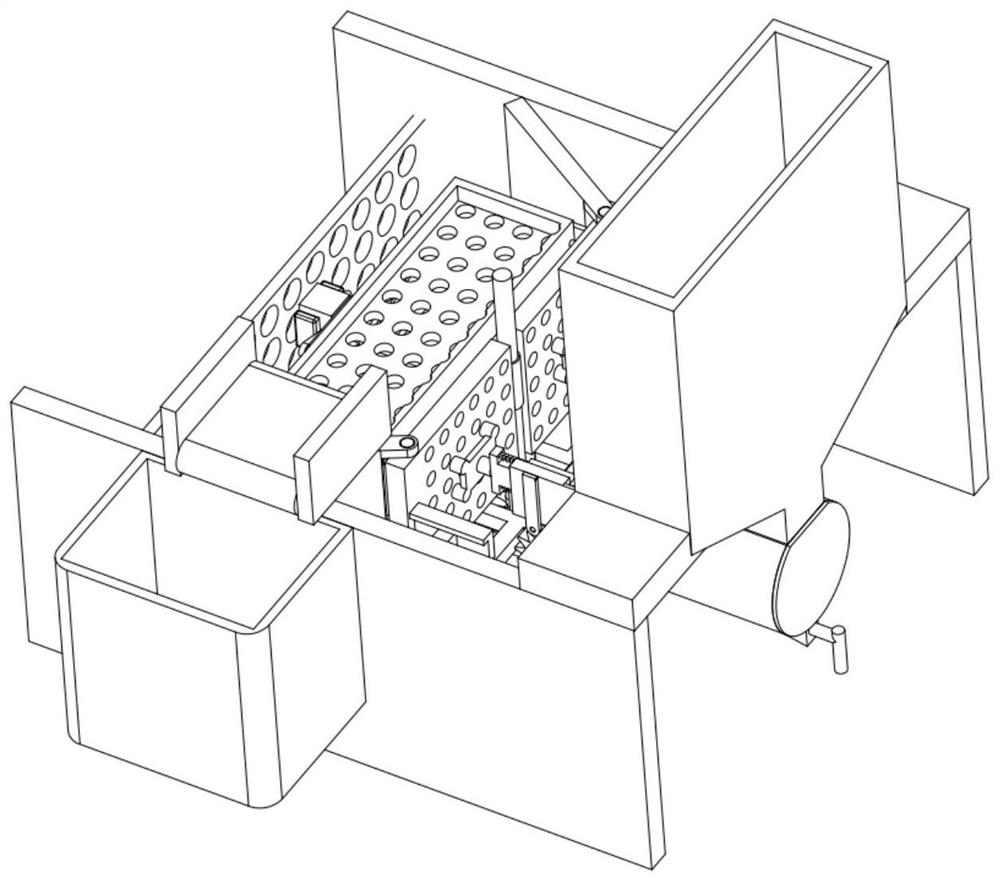

Follow fixture library device and automatic fixture switching system and method

PendingCN112372180ASmall footprintIncrease usable areaWelding/cutting auxillary devicesAuxillary welding devicesProcess engineeringAssembly line

The invention discloses a follow fixture library device and an automatic fixture switching system and method. The follow fixture library device comprises a base, a rotating mechanism and a columnar placing base, the rotating mechanism is arranged in the center of the base, the columnar placing base is arranged on the rotating mechanism, at least two mounting surfaces are arranged on the peripheralsurface of the columnar placing base, and at least one placing assembly for placing an assembling clamp is arranged on each mounting surface. The automatic fixture switching system comprises at leastone switching robot used for replacing fixtures for an assembly line, at least one follow fixture library device and a controller, and the switching robots and the rotating mechanisms of the follow fixture library devices are both connected with the controller. Due to the fact that the columnar placing base of the follow fixture library device has the advantages of being small in occupied space and capable of containing a large number of fixtures, the effects that the overall occupied space of the automatic fixture switching system is small, and the fixture replacing efficiency is high are achieved.

Owner:SAIC-GM-WULING AUTOMOBILE CO LTD

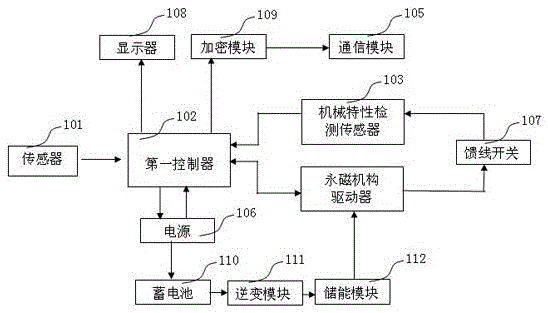

Power distribution network feeder terminal unit

InactiveCN105610242ARealize the effect of automationRealize the online monitoring function of mechanical characteristicsMachine part testingCircuit arrangementsFeed lineDistribution grid

The invention discloses a power distribution network feeder terminal unit. With the power distribution network feeder terminal unit adopted, the problem of relatively low automation performance and incapability of realizing fast fault detection fast of an existing jsh can be solved. The power distribution network feeder terminal unit is characterized in that the first input end of a first controller is connected with the output end of a sensor, the second input end first controller is connected with the output end a mechanical characteristic detection sensor; the first output end of the first controller is connected with the input end of a permanent magnetic actuator, and the second output end of the first controller is connected with a communication module; the output end of the permanent magnetic actuator is connected with the input end of a feeder switch; the output end of the feeder switch is connected with the input end of the mechanical characteristic detection sensor; and a power source is connected with the first controller and the permanent magnetic actuator. The automation performance of the feeder terminal can be realized; fault detection efficiency can be improved; and on-line monitoring on the mechanical characteristics of the body of the feeder switch can be realized.

Owner:HUAIBEI POWER SUPPLY COMPANY OF STATE GRID ANHUI ELECTRIC POWER +1

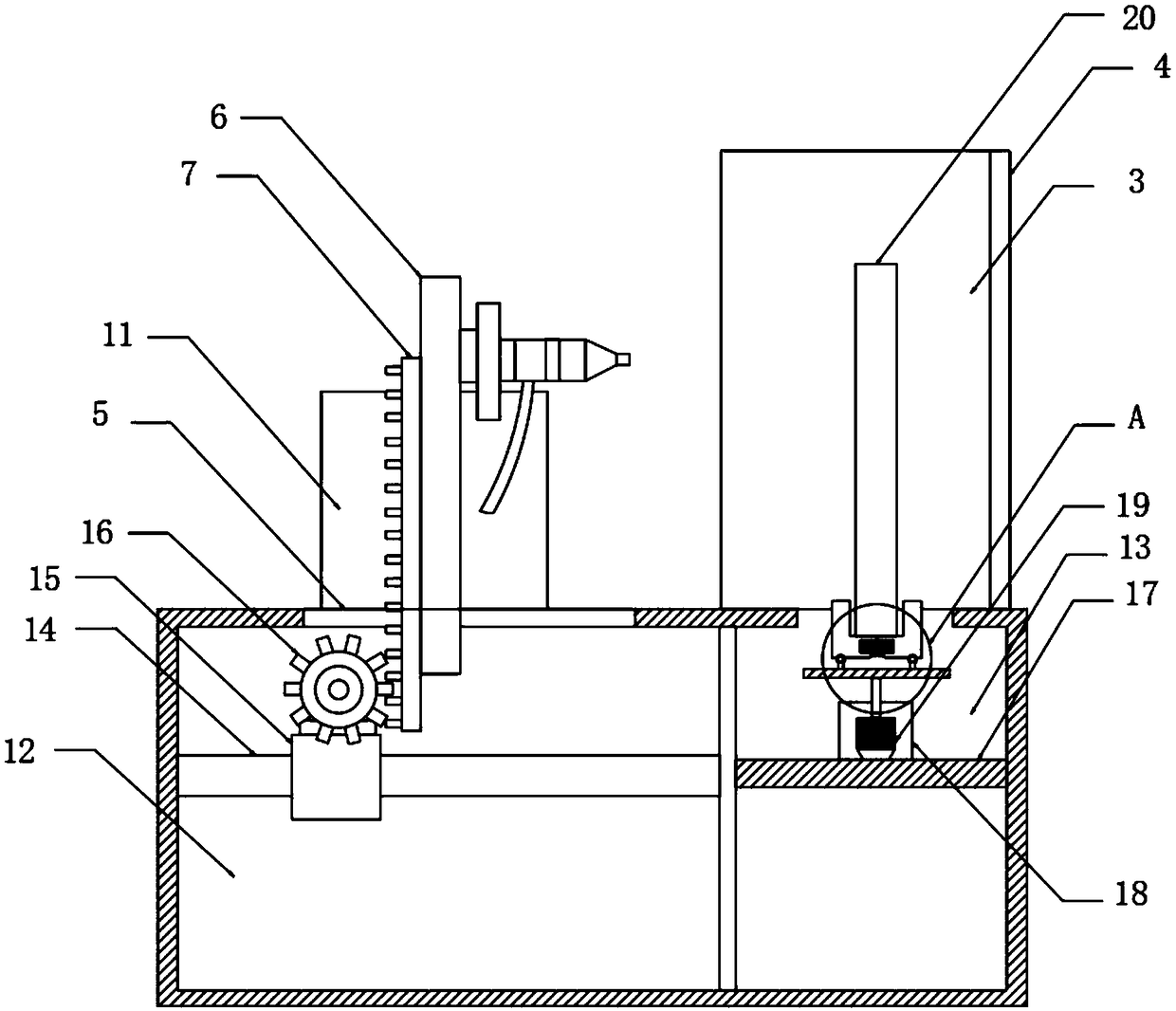

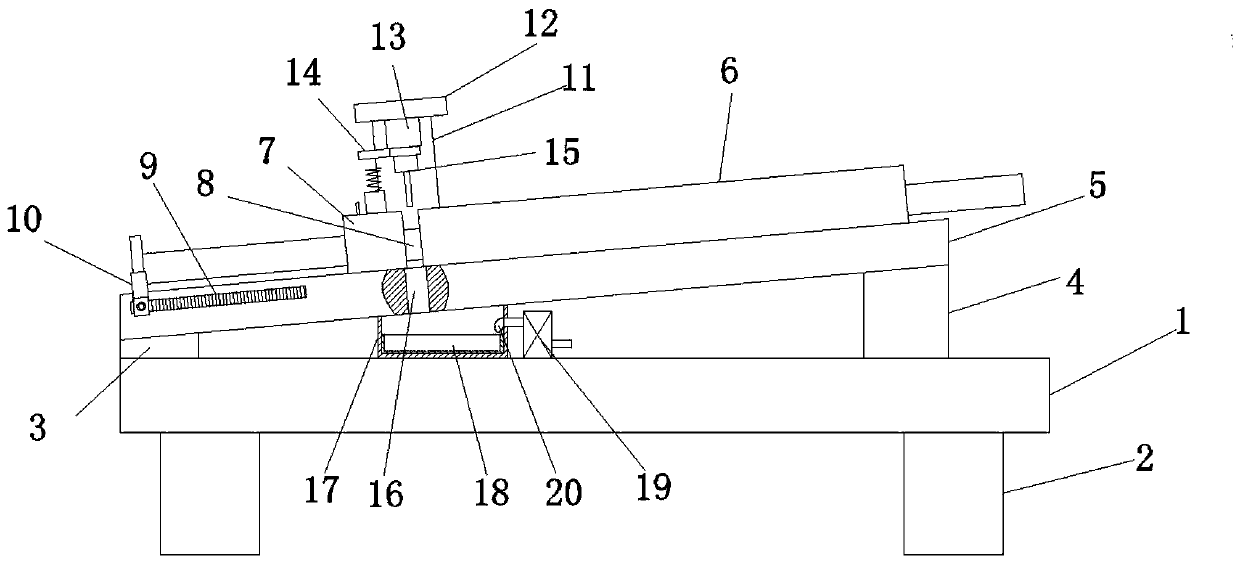

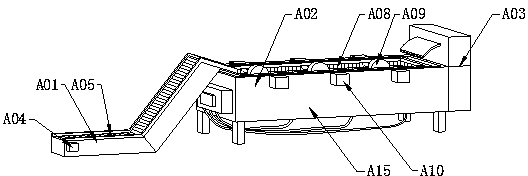

Quartz pipe cutting device

ActiveCN109773987ARealize automatic feedingAvoid chippingFine working devicesSlagWorking environment

The invention discloses a quartz pipe cutting device in the technical field of quartz production. The quartz pipe cutting device comprises a worktable; supporting legs are laterally symmetrically arranged on the bottom end of the worktable; a first supporting foot and a second supporting foot are separately arranged on the left and right sides of the top end of the worktable; an oblique plate anda sleeve pipe mechanism are arranged, so that an automatic feeding process of a quartz pipe can be realized; a certain automation effect is realized; no manual adjustment is not needed; a cutting clearance is arranged, so that stress near the a cutting surface is uniform during cutting of the quartz pipe; a cracking condition is avoided; a spring and an arc plate structure are arranged on the bottom of a short sleeve pipe, so that during work of the cutting device, the quartz pipe can be compacted; vibration of the quartz pipe during cutting is reduced; cracking of the quartz pipe is further avoided; an exhaust fan dusting structure is arranged, so that slags and powder generated during the cutting process can be absorbed in time; the working environment is protected; and a slide chute andan interval-adjusting mechanism are arranged, so that cutting sizes can be changed.

Owner:DONGHAI COUNTY KAIKAI QUARTZ PROD CO LTD

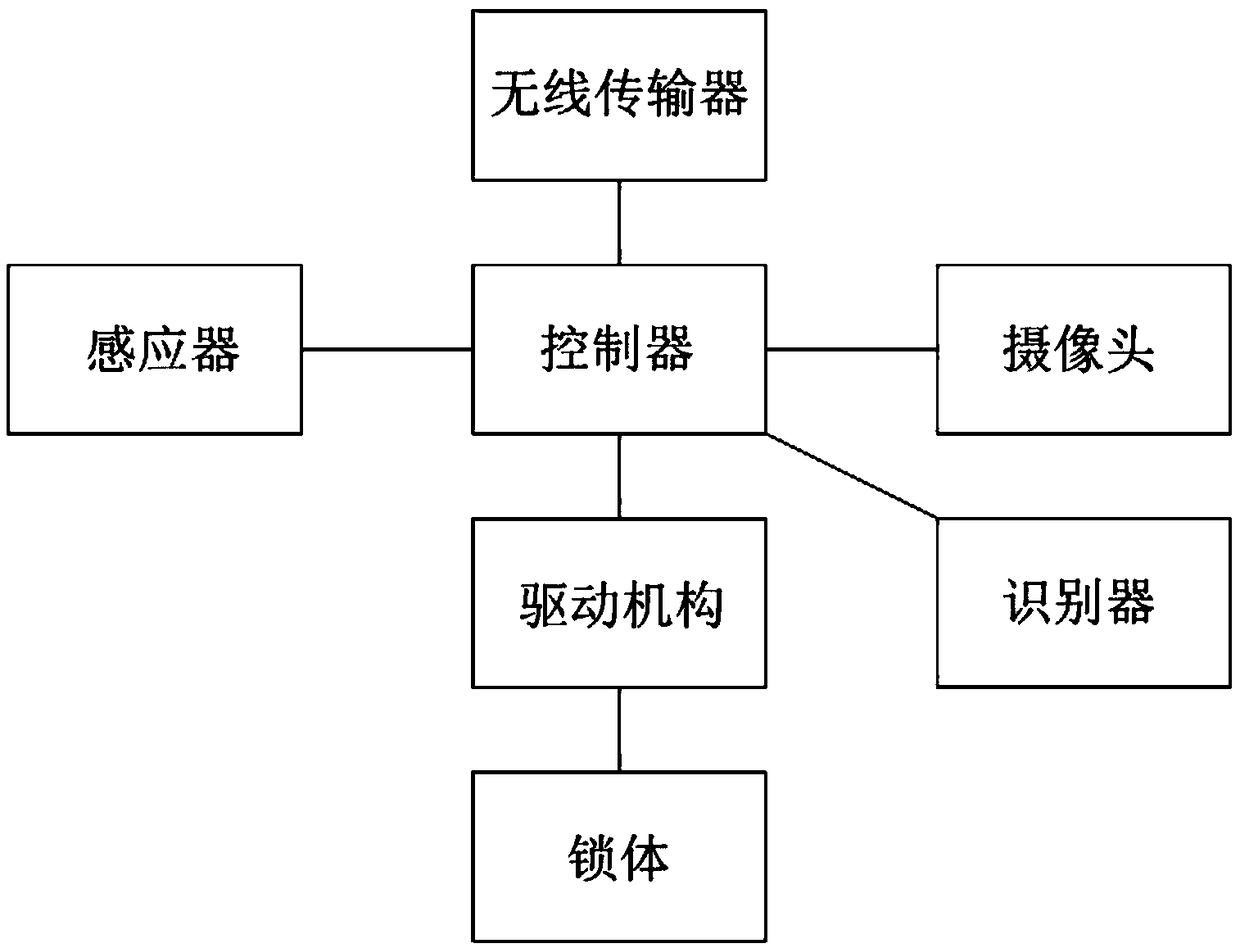

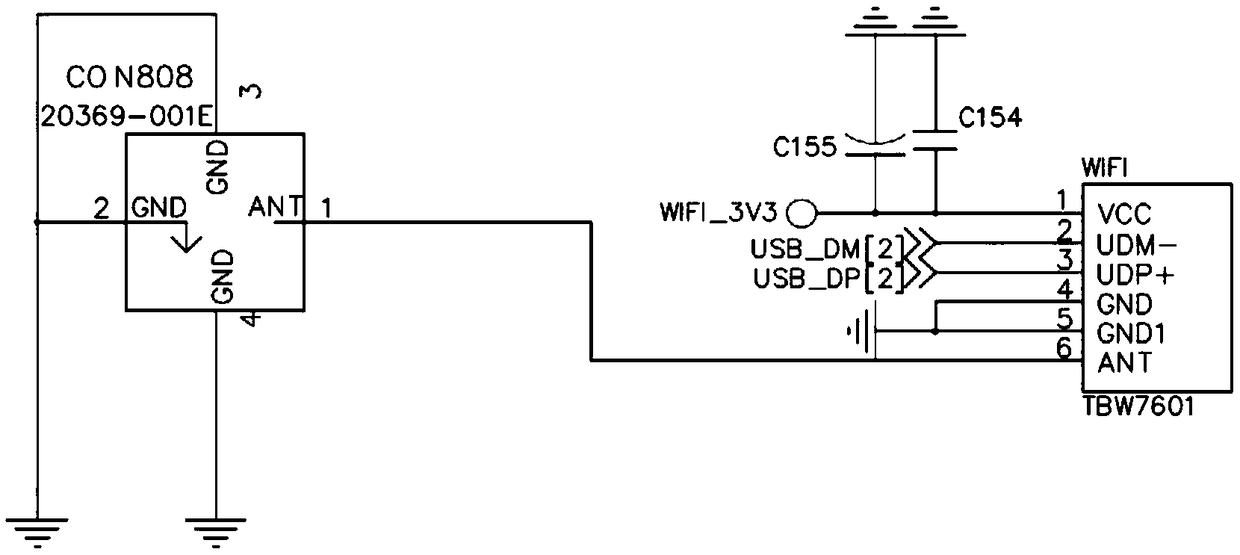

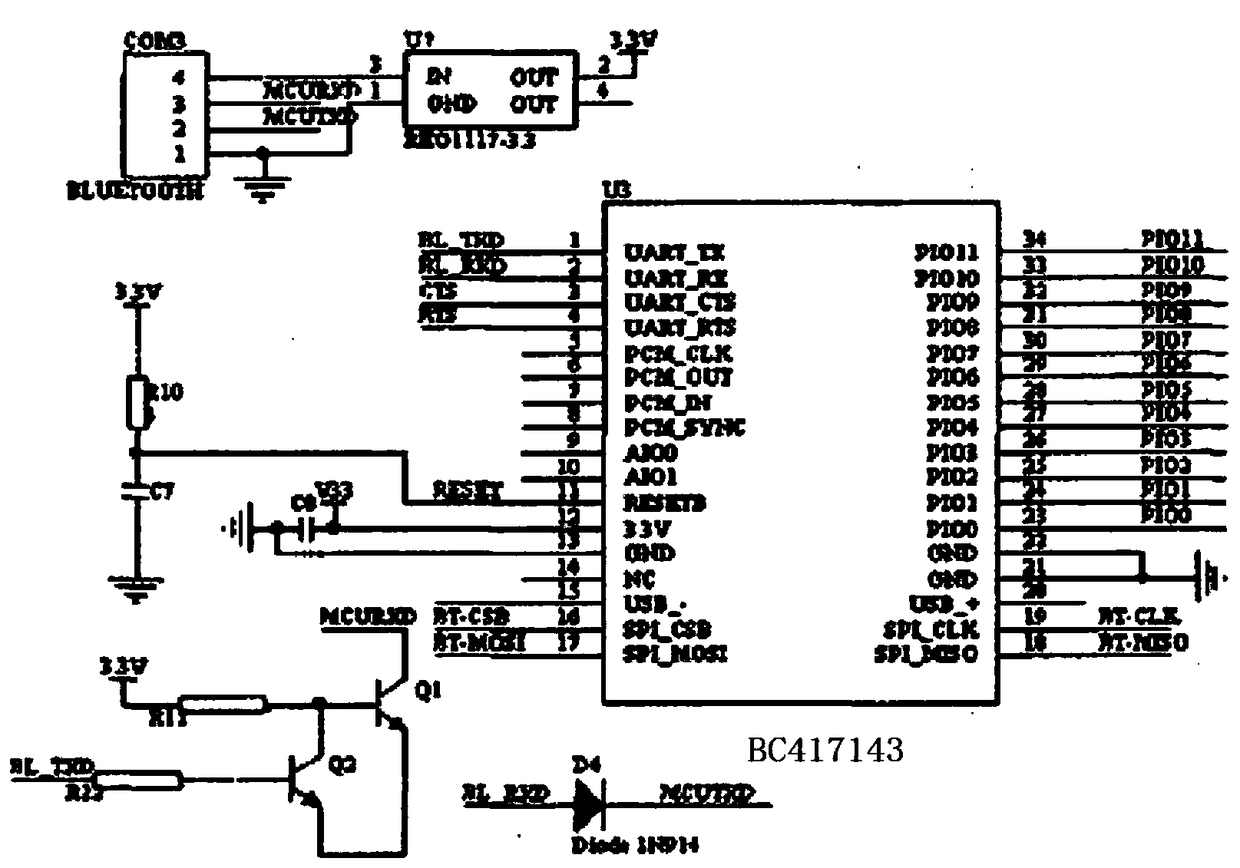

Automatic monitoring door lock

PendingCN109209039ARealize the effect of automationImprove securityTransmission systemsNon-mechanical controlsElectronic identificationInductor

The present invention relates to the technical field of locksets, especially to an automatic monitoring door lock. The automatic monitoring door lock comprises a lock body, a controller, a wireless transmitter, a camera, an inductor and a drive mechanism configured to drive switching of the lock body; the wireless transmitter, the drive mechanism and the camera are connected with the controller, and the drive mechanism is connected with the lock body; the automatic monitoring door lock further comprises an identifier which is connected with the controller. The automatic monitoring door lock employs the wireless transmitter, the inductor and the camera with cooperation to achieve remote monitoring of conditions of peoples out of rooms so as to improve the safety and the anti-theft performance. The identifier and the portable electronic identification tag are cooperated to achieve the automatic effect of a non-contact locking.

Owner:东莞市腾达五金制品有限公司

Spraying device suitable for flue gas purification tower

ActiveCN112843991ARealize the effect of automationNo action requiredGas treatmentUsing liquid separation agentThermodynamicsFlue gas

The invention relates to the technical field of air purification devices, and in particular, relates to a spraying device suitable for a flue gas purification tower. The spraying device comprises an incinerator, a water supplementing tank and two spraying heads; the water supplementing tank is fixedly mounted in the incinerator, the spraying heads are symmetrically arranged relative to the water supplementing tank, and a heat collecting head is fixedly mounted on the water supplementing tank; a preparation cavity communicated with the water supplementing tank is formed in the heat collecting head, an air bag is arranged in the preparation cavity, a sliding plate mounted in the preparation cavity in a sliding mode is arranged over the air bag, a valve piece used for controlling water supplementing work is arranged between the water supplementing tank and the preparation cavity, and the spraying heads are movably arranged in the incinerator; and a rotating vane is rotationally mounted in the preparation cavity, and a push-out mechanism is arranged between the rotating vane and each spraying head. According to the spraying device, by adopting the mode that a small number of spraying heads are matched with the push-out mechanisms, spraying work on different positions is achieved, the practicability of the spraying heads is improved, and the cost of the whole device is reduced.

Owner:利晟(杭州)科技有限公司

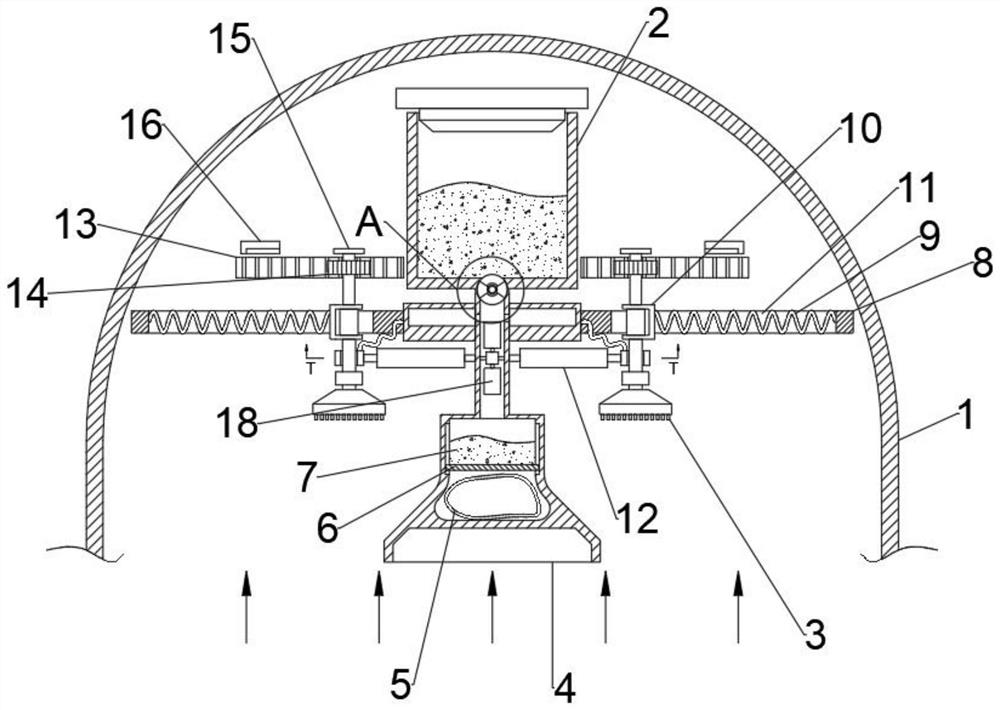

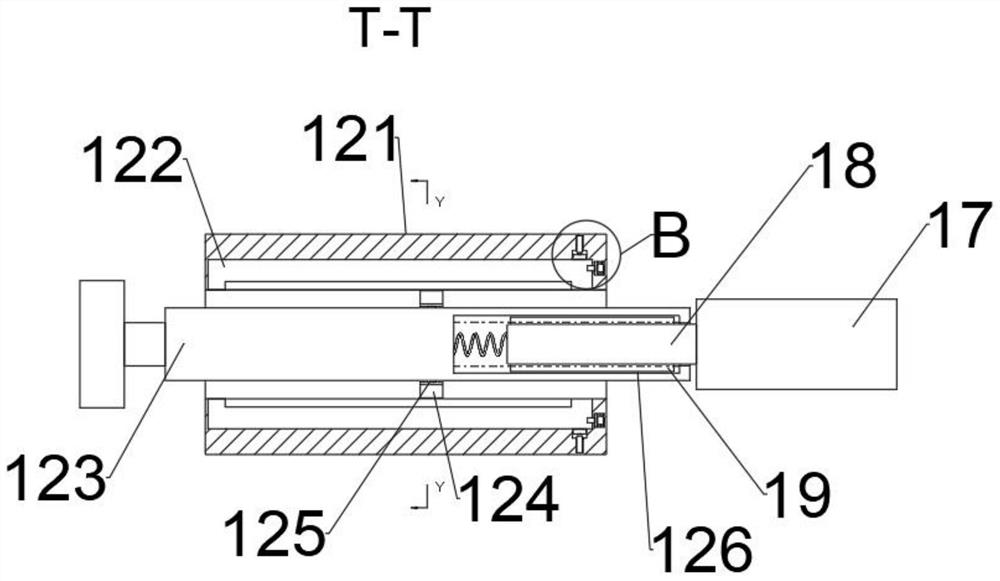

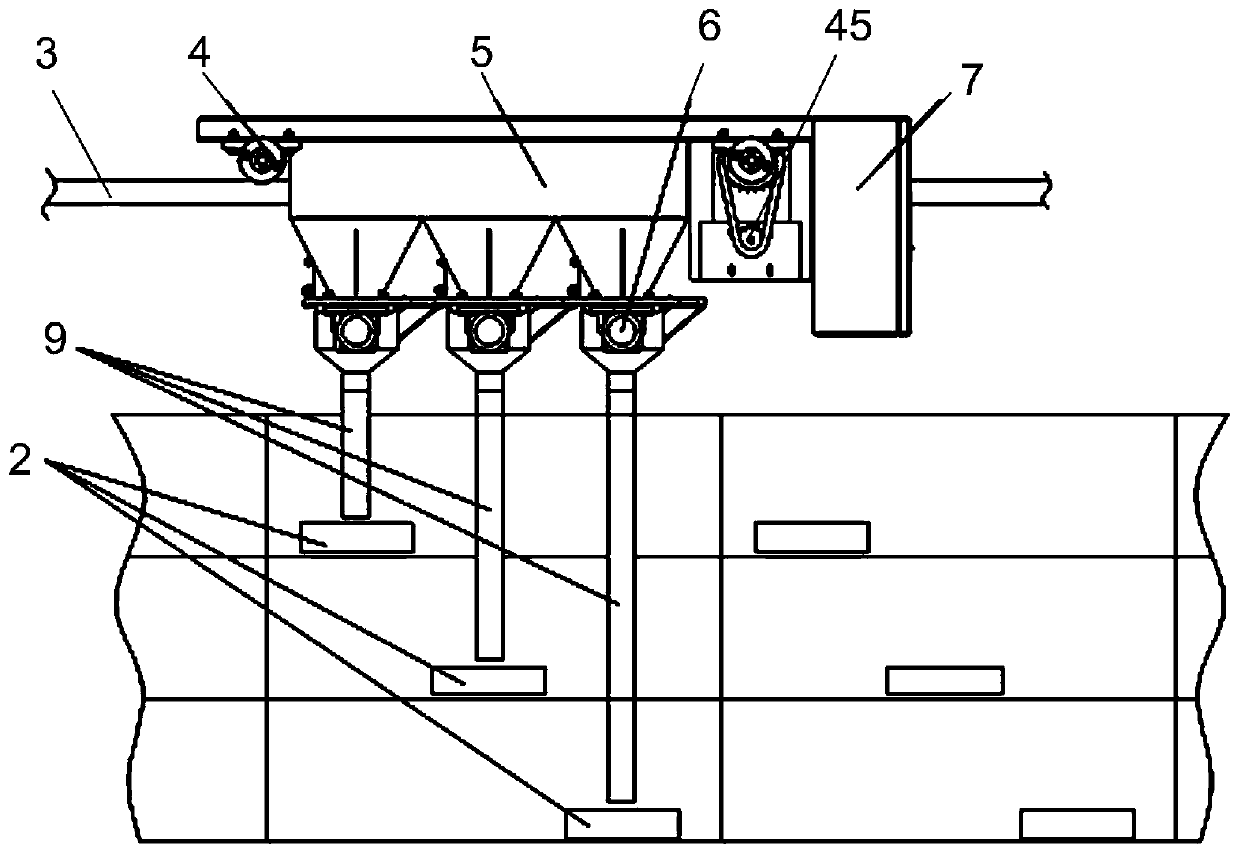

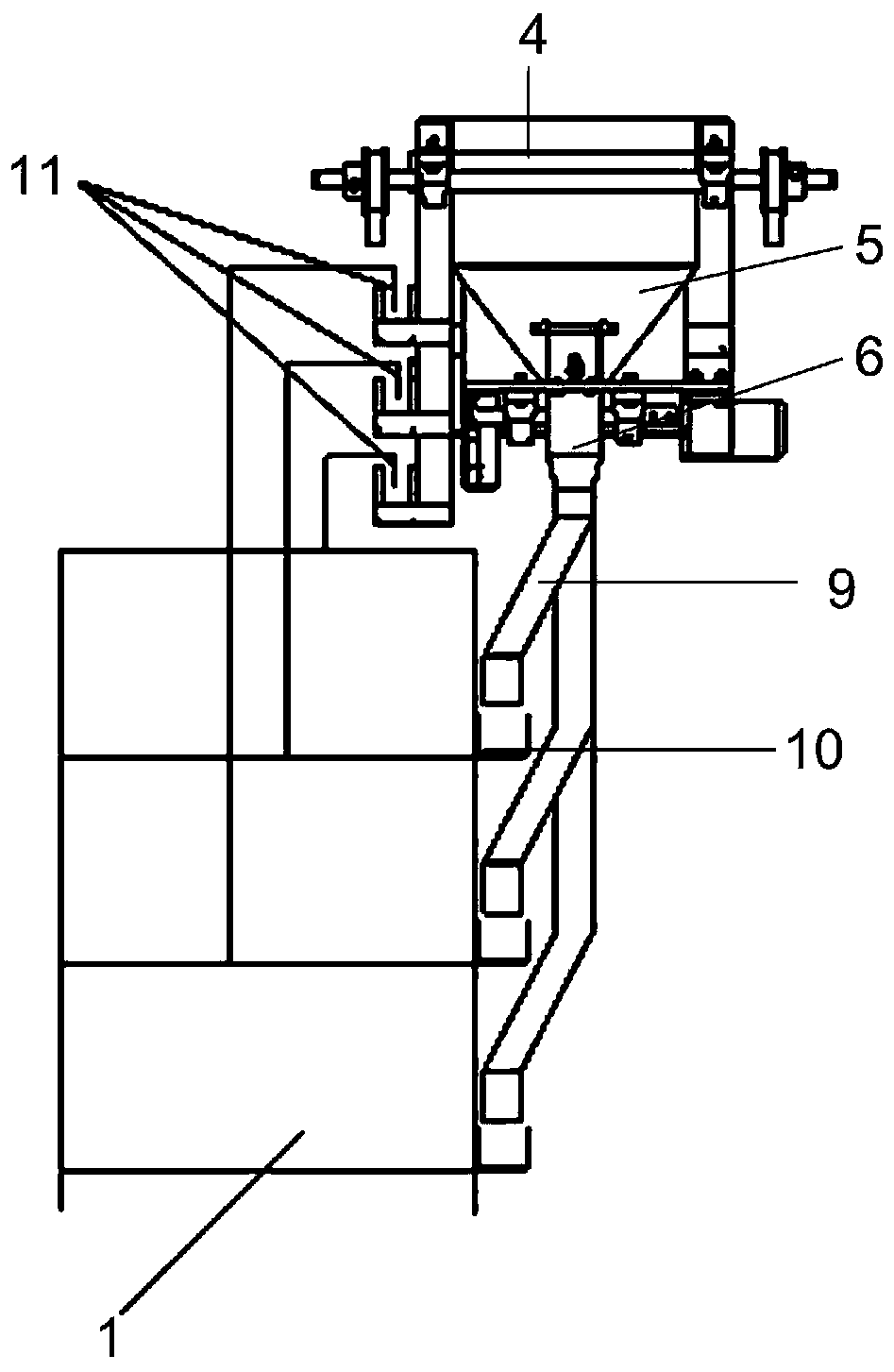

Intelligent feeder

PendingCN111165385ARealize the effect of automationLow costBird housingsControl engineeringElectric machinery

The invention is applicable to the technical field of mechanized feeding, and provides an intelligent feeder. The intelligent feeder comprises a multi-layer cage body, a plurality of material groovesarranged in the multi-layer cage body, oppositely arranged guide rails, a vehicle body slidably arranged on the guide rails, a plurality of oppositely arranged hoppers, a plurality of feeding assemblies correspondingly arranged under the plurality of hoppers, and a control device, wherein the plurality of hoppers are fixedly arranged under the vehicle body, a plurality of discharging pipes are fixedly arranged under the plurality of feeding assemblies, the plurality of discharging pipes correspond to the plurality of material grooves, and the control device is used for controlling the vehiclebody and the plurality of feeding assemblies; and each of the multiple feeding assemblies comprises a bottom plate, a measuring cup, a measuring cup wheel, a measuring cup wheel shaft, a bearing, a first motor, a discharging bin and a travel switch, the first motor is fixedly arranged under the bottom plate, the first motor is in transmission connection with the measuring cup wheel shaft, the bearing is oppositely arranged on the measuring cup wheel shaft, and the discharging bin communicates with the discharging pipe. According to the intelligent feeder, the utilization rate and the economicbenefit of the feed can be greatly improved, and the intelligent feeder is convenient to popularize and use.

Owner:苏少华

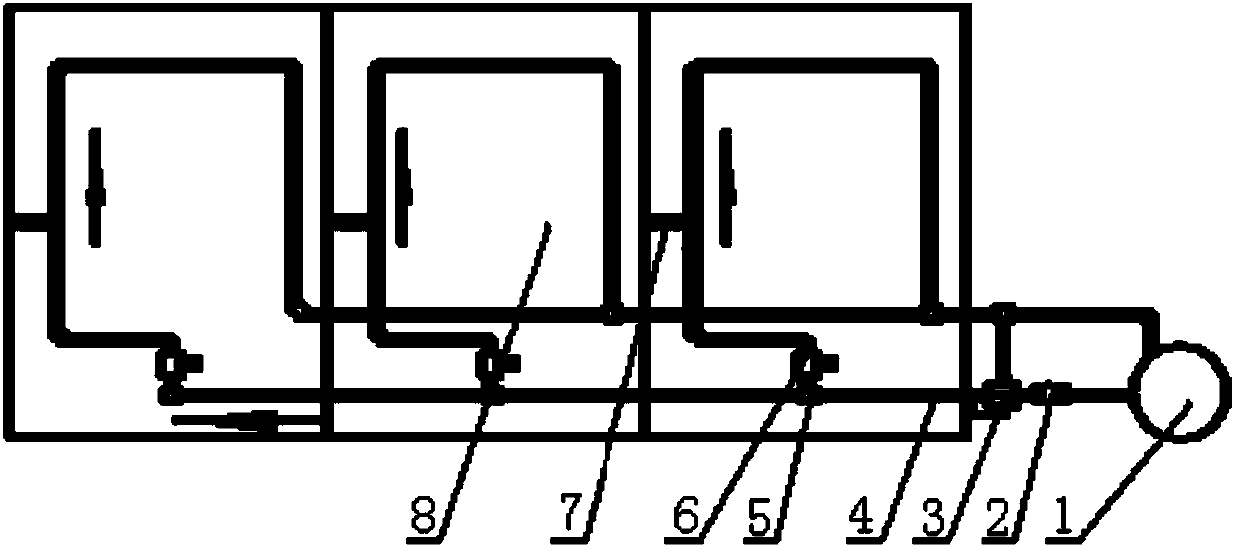

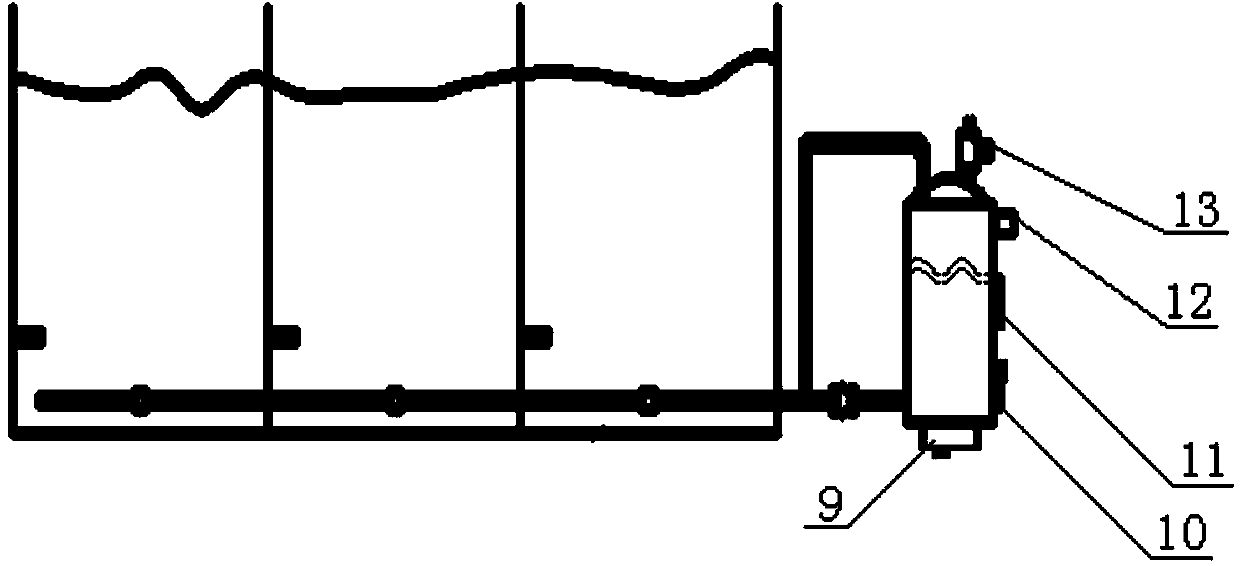

Automatic heating device and automatic heating method for seawater seedling culture pond

InactiveCN103734077AReasonable structureEliminate misusePisciculture and aquariaEngineeringType safety

The invention relates to an automatic heating device and an automatic heating method for a seawater seedling culture pond. A temperature relay is installed between the middle of a water inlet pipe and the seedling culture pond. A magnetic control valve is installed above a tee joint. A controllable electric heater for heating a water receiver is installed under the water receiver, a temperature control type safety valve, a temperature sensor and a water level controller are installed on the side of the water receiver, and a magnetic water injection valve is installed at the top of the water receiver. The operation method comprises that the temperature control type safety valve detects water temperature of the water receiver; the temperature sensor sends a signal to the controllable electric heater when the water temperature of the water receiver is lower than 50 DEG C; the water level controller at the lower portion of the water receiver controls the height of hot water in the water receiver; the magnetic water injection valve begins to work when receiving an instruction sent by the temperature relay; a pressure hot water delivery pump always works when the magnetic control valve is closed. The automatic heating device has the advantages of being simple in structure, high in automation degree and safe and convenient to use, reducing energy consumption and the like.

Owner:舟山市普陀兴海养殖优质种苗选育研究所

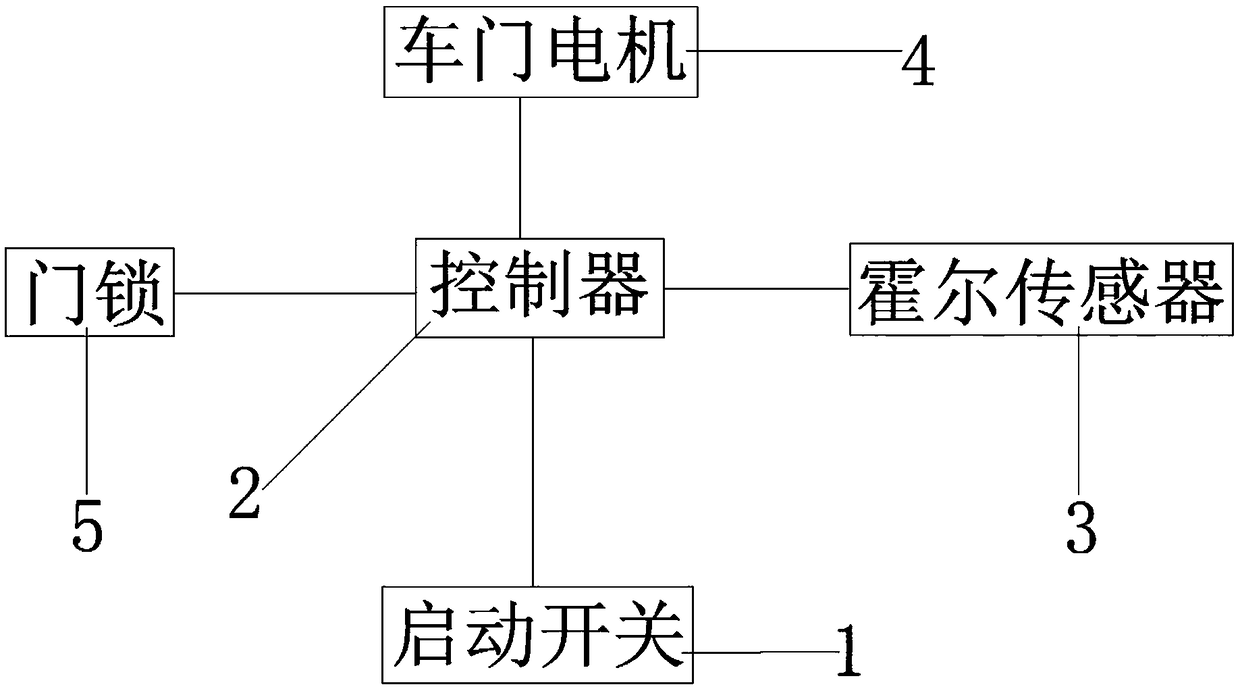

Automobile electric sliding door system

InactiveCN109267888ARealize the function of automatic door lockRealize the effect of automationPower-operated mechanismElectrical locking actuatorsAutomationElectrical and Electronics engineering

The invention discloses an automobile electric sliding door system. The automobile electric sliding door system includes a starting switch, a controller, an automobile door motor, a Hall sensor and adoor lock; the controller is connected with the starting switch, the automobile door motor, the Hall sensor and the door lock separately, the starting switch initiates a door opening signal, after thecontroller receives the signal, the signal is transmitted to the Hall sensor, the Hall sensor judges the position state of an automobile electric sliding door and feeds back the signal to the controller, and after receiving the signal fed back by the Hall sensor, the controller controls the automobile door motor to start or not. According to the automobile electric sliding door system, by converting a traditional manual sliding door into the automobile electric sliding door, the automobile electric sliding door is protected; currently, the traditional manual sliding door is opened and closedmanually and thus is easily collided and damaged, and accordingly the service life of an automobile is influenced; the door lock is controlled by a controller, so that an automatic door locking function is achieved; the automobile electric sliding door has a clamping prevention function and thus is safer than the traditional manual sliding door, and a full automation effect is achieved.

Owner:南京然之汽车科技有限公司

Tea carding machine capable of realizing tea discharge conveniently

ActiveCN105248684AReduce labor intensityAvoid injuryPre-extraction tea treatmentReciprocating motionAgricultural engineering

The invention discloses tea production equipment and particularly relates to a tea carding machine capable of realizing tea discharge conveniently. The tea carding machine comprises a rack, a pot rack reciprocating on the rack and a grooved pot mounted on the pot rack, wherein the grooved pot comprises a plurality of U-shaped grooves, each U-shaped groove comprises two side plates and two arc plates hinged to the lower ends of the side plates, and the two arc plates are closed to constitute the bottom of the U-shaped groove; a control mechanism for controlling opening and closing of the arc plates is arranged on the rack and comprises Y-shaped support columns and hydraulic columns connected with lower parts of the Y-shaped support columns, each Y-shaped support column comprises three supports, the three supports of each Y-shaped support column are hinged to the same hinged point, two upward supports of each Y-shaped support column are hinged with two opposite arc plates respectively, and the length sum of the two upward supports is larger than an interval between the adjacent hinged points when the arc plates are in the closed state. When the tea carding machine is used for tea discharge, the arc plates at the bottom of the U-shaped grooves are opened, tea drops on a conveying belt below the arc plates, and accordingly, the tea discharge is realized.

Owner:天津思度工业设计有限公司

Foaming stirrer for osmunda japonica thunb and application method thereof

InactiveCN108142959AFully cleanedSolve the problem of incomplete cleaningRotary stirring mixersTransportation and packagingWater filterEngineering

The invention provides a foaming stirrer for osmunda japonica thunb and an application method thereof, and relates to the field of stirrers. The foaming stirrer comprises a stirrer body, wherein the stirrer body mainly consists of a transmission machine tank, a foaming washing machine and a water filter; and a motor is arranged on the left side of the transmission machine tank, and is electricallyconnected with the transmission machine tank. The foaming stirrer for osmunda japonica thunb disclosed by the invention combines functions of a conventional vegetable washer; stirring wheels are arranged, and are connected by a transmission rod; the two ends of the transmission rod are connected with electric motors; the electric motors rotate the stirring wheels in the left-right direction; osmunda japonica thunb in water is stirred by stirring rollers arranged at the bottoms of the stirring wheels, is scattered and washed, so that the osmunda japonica thunb is rolled in a material sieving frame, and is more thoroughly washed; the design that the osmunda japonica thunb foaming stirrer not only can stir the osmunda japonica thunb but also can foam to rinse the osmunda japonica thunb is realized; the problem that in the past, vegetables can be washed only in a soaking manner and cannot be washed in a rolling manner, and silt at the tops of the vegetables cannot be completely dischargedout of the material sieving frame, so that the washing is not thorough is solved; and the foaming stirrer for osmunda japonica thunb has favorable development prospects.

Owner:丁年生

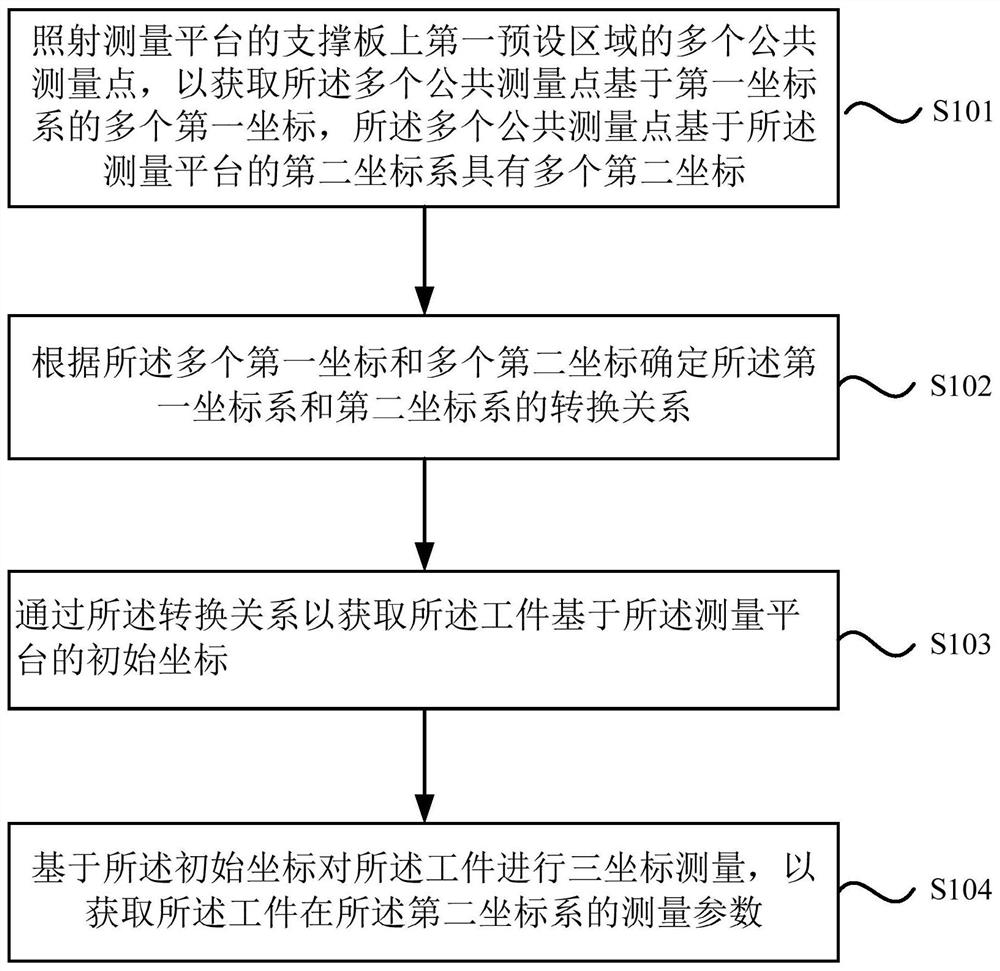

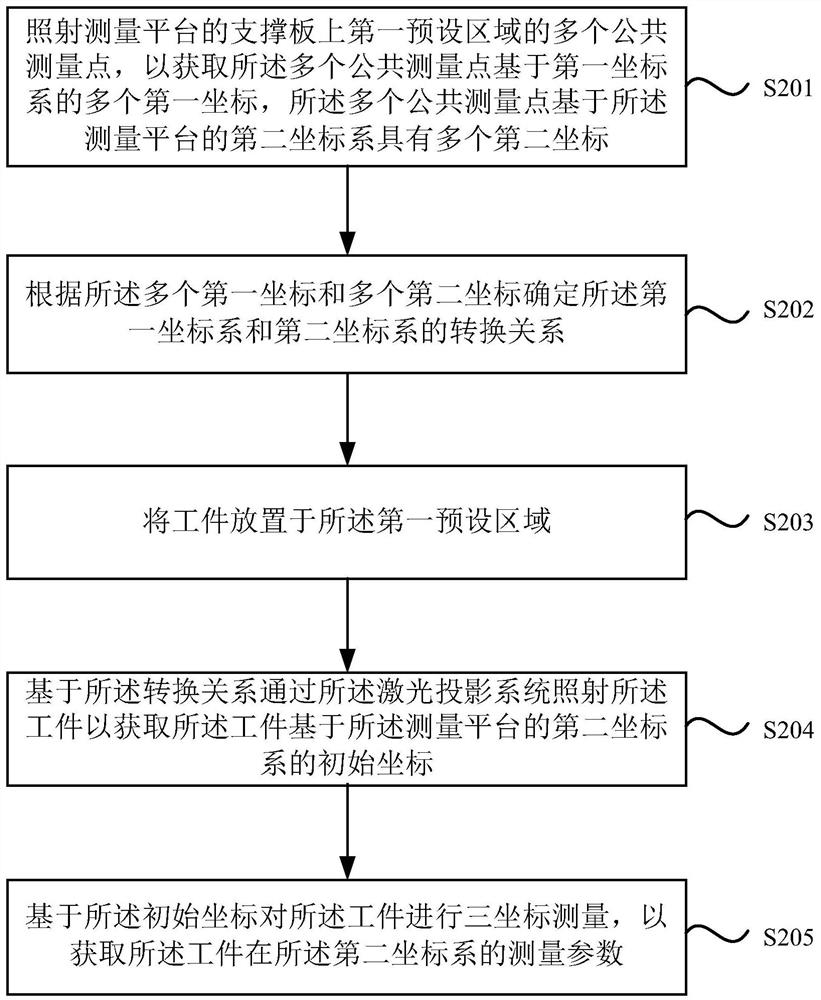

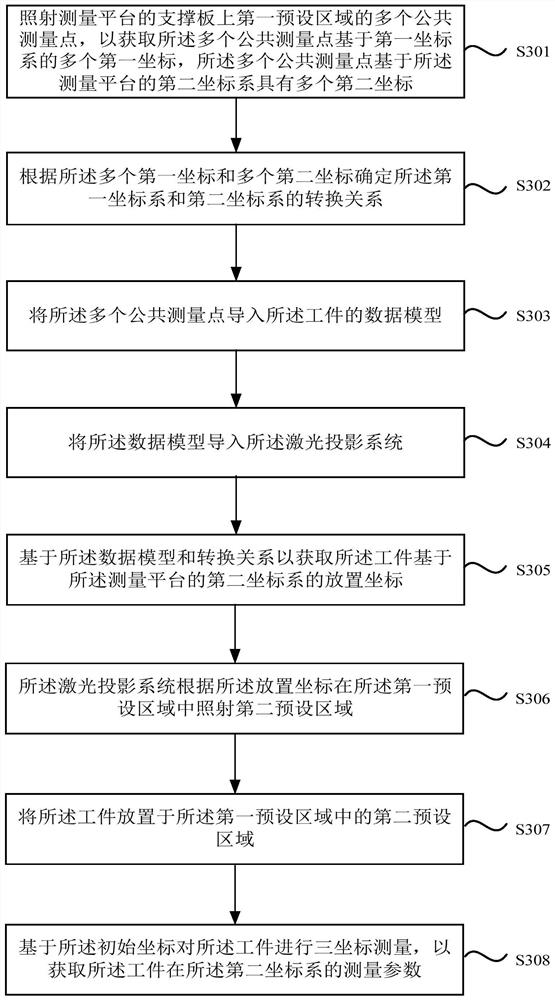

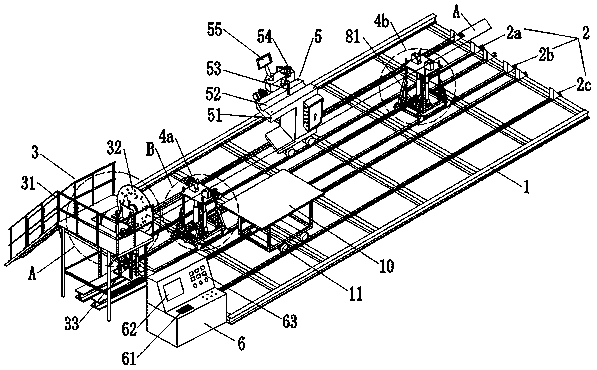

Three-coordinate measuring method and device for workpiece, equipment and storage medium

ActiveCN112414340ARealize the effect of automationSolve problems that require manual alignmentMeasurement devicesControl engineeringProcess engineering

The embodiment of the invention discloses a three-coordinate measuring method and device for a workpiece, equipment and a storage medium. The measurement method comprises the steps of irradiating a plurality of common measurement points of a first preset area on a supporting plate of a measurement platform to obtain a plurality of first coordinates of the plurality of common measurement points based on a first coordinate system, wherein the plurality of common measurement points have a plurality of second coordinates based on a second coordinate system of the measurement platform; determininga conversion relationship between the first coordinate system and the second coordinate system according to the plurality of first coordinates and the plurality of second coordinates; obtaining an initial coordinate of the workpiece based on the second coordinate system of the measurement platform through the conversion relationship; and performing three-coordinate measurement on the workpiece based on the initial coordinates to obtain measurement parameters of the workpiece in the second coordinate system. According to the embodiment of the invention, automation of three-coordinate measurement of different types of workpieces is realized.

Owner:SHANGHAI AIRCRAFT MFG

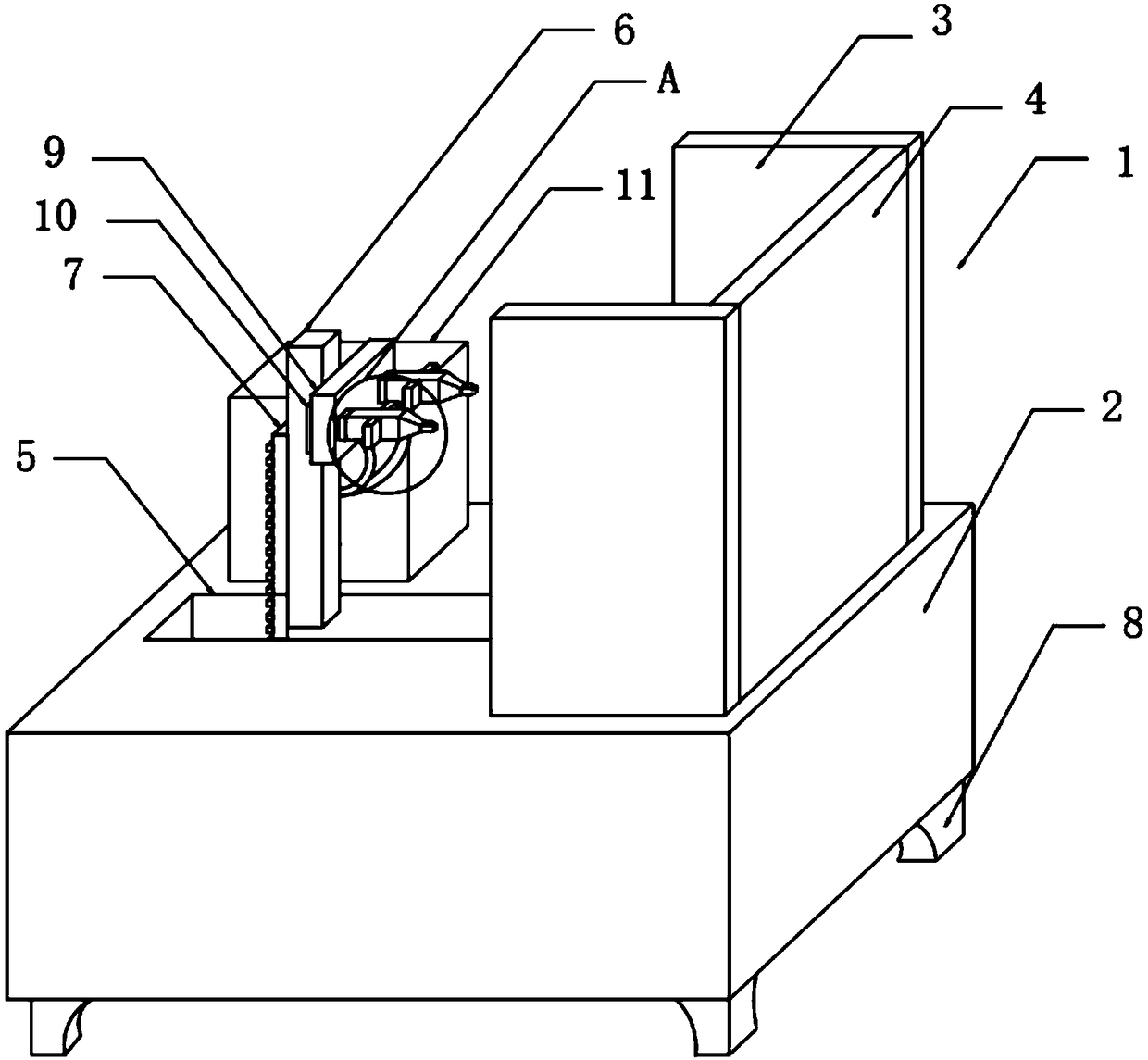

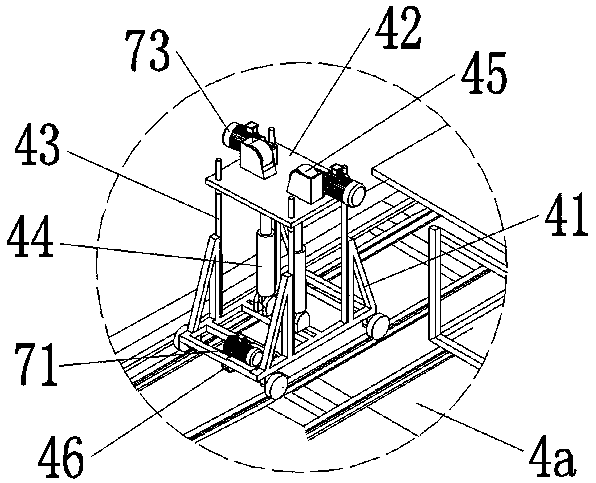

Automatic welding working platform of steel structure

PendingCN109702393ARealize automatic processing and weldingRealize the effect of automationWelding/cutting auxillary devicesAuxillary welding devicesEngineeringMachining

The invention relates to an automatic welding working platform of a steel structure. The platform comprises a platform bottom frame base and a pulley rail arranged on the platform bottom frame base, wherein supporting mechanisms, a welding machine and a tool operating platform are arranged on the pulley rail, and a rotary indexing mechanism and a control panel are arranged at the left end of the platform bottom frame base. The supporting mechanisms comprise a first supporting mechanism and a second supporting mechanism, the first supporting mechanism, the second supporting mechanism, the welding machine and the tool operating platform are all provided with foot pulleys matched with the pulley rail, the control panel controls vertical lifting of the rotary indexing mechanism and the supporting mechanism and the horizontal movement of the supporting mechanism, and the welding machine is provided with an existing pneumatic type automatic welding system. According to the platform, the rotary indexing mechanism is provided with an annular graduated scale for measuring the rotation angle of a workpiece A, the two ends of the workpiece A are supported by the supporting mechanism and the left end of the workpiece A is fixed on a circular rotary disc of the rotary indexing mechanism, then the welding machine is used for carrying out automatic machining and welding, so that the automaticoperation is realized, the labor cost is reduced, and the requirements of an existing market are met.

Owner:石挺峰

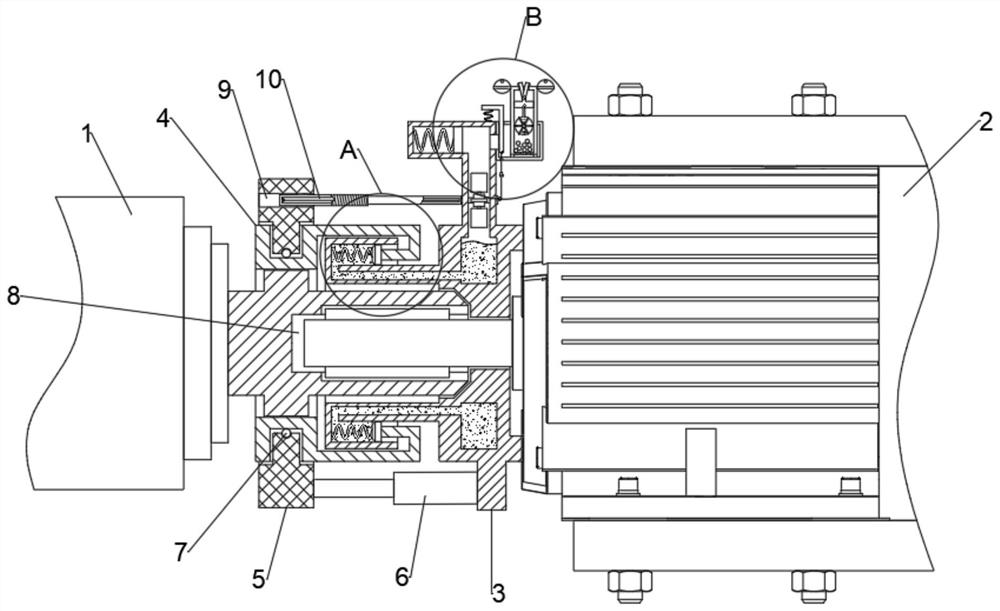

Roller auxiliary safe and stable connecting structure

ActiveCN112536323ARealize the effect of automationMetal rolling stand detailsRolling equipment maintainenceElectric machineryEngineering

The invention relates to the technical field of roller installation, in particular to a roller auxiliary safe and stable connecting structure. The roller auxiliary safe and stable connecting structurecomprises a roller and a motor; a static connecting disc is fixedly installed on the motor; the outer wall of one end of the roller is sleeved with a movable connecting disc; the movable connecting disc is in threaded fit with one end of the roller; the static connecting disc and the movable connecting disc are connected through a telescopic rod; a shaft groove is arranged in the roller; an output end of the motor is clamped in the shaft groove in a sliding mode; a damping cavity is arranged in the static connecting disc; the outer wall of the static connecting disc is sleeved with a hollow piston; the piston is installed in the damping cavity in a sliding mode; and the piston is connected to the damping cavity through a connecting piece. According to the invention, through the arrangement of an early warning assembly and a linkage structure, the automation effect is achieved, a worker does not need to check the device regularly; and the worker can know the situation at the first timein case of an emergency.

Owner:HEBEI INST OF MACHINERY ELECTRICITY

A purification device for attapulgite

The invention discloses an attapulgite purifying device, and relates to the technical field of attapulgite processing. The device comprises an outer barrel and an inner barrel arranged in the outer barrel. The outer barrel and the inner barrel share a same axial lead and both have a horizontally arranged cylindrical structure. The inner barrel has a front opening and a rear opening. The front opening and the rear opening are fixedly connected to the internal wall of the outer barrel. The device can purify attapulgite, is applied to the primary processing of attapulgite, is convenient to use, is simple to operate, and is very practical and flexible.

Owner:MINGGUANG FEIZHOU NEW MATERIAL

Urine FXYD detection kit

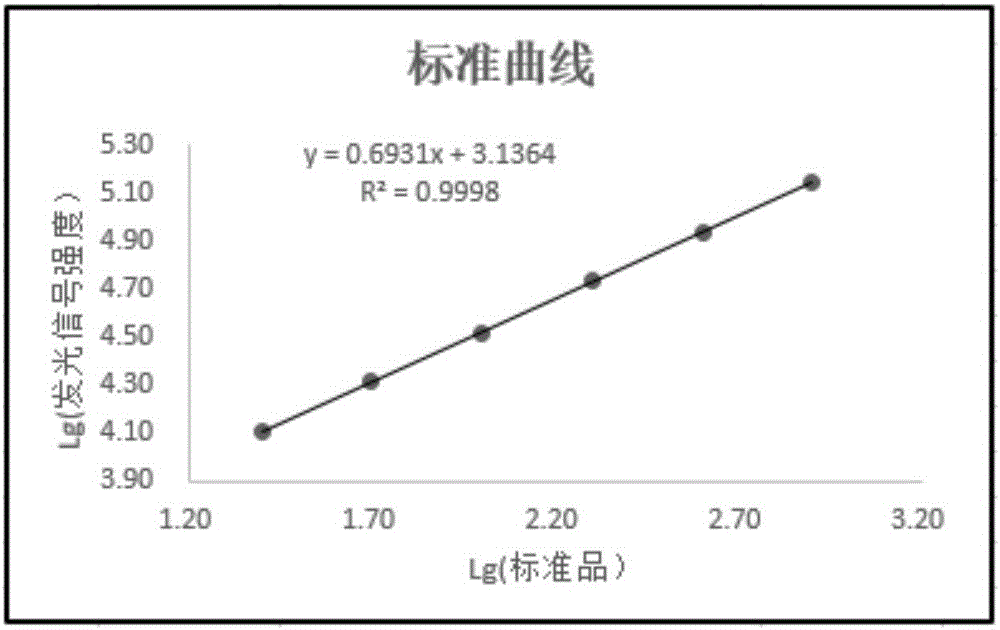

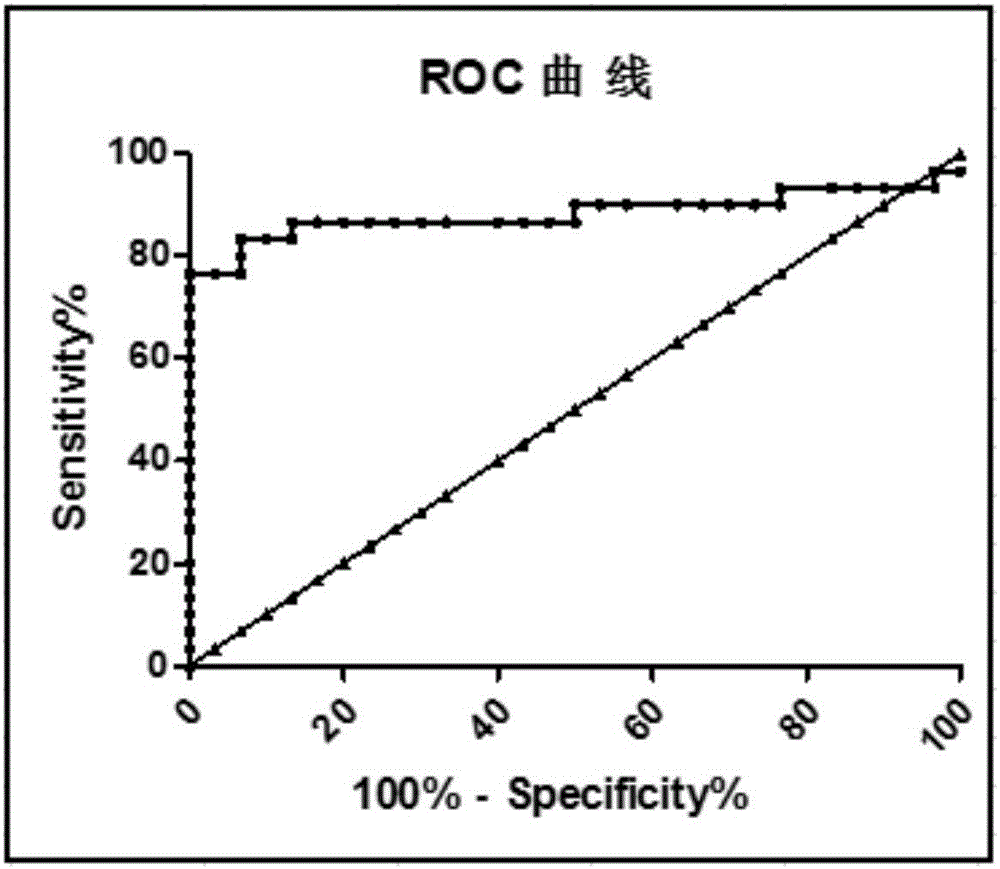

InactiveCN106680482AIncrease exposureShort reaction timeMaterial analysisLymphatic SpreadFibrinogen degradation product

The invention discloses a urine FXYD detection kit. The kit comprises the following components: magnetic particles which are coupled with anti-FXYD antibodies, anti-FXYD polyclonal antibodies labeled with enzyme; FXYD standard substances; chemiluminescent substrate liquid. The kit can be used for quantitative determination of fibrinogen degradation product components FXYD in urine, and the kit has the characteristics of short detection time, high sensitivity, good stability, and small variation; and the kit can be used for early stage diagnosis of intestinal cancer, curative effect evaluation in treatment process, and recurrence and metastasis monitoring after treatment.

Owner:SHANGHAI LIANGRUN BIOMEDICINE TECH CO LTD

Ditch sundry blocking and clearing equipment

InactiveCN112854158ASave human effortReduce labor costsWater cleaningRenewable energy machinesFertilizerAgricultural engineering

The invention discloses ditch sundry blocking and clearing equipment. The ditch sundry blocking and clearing equipment comprises a ditch channel, a garbage dumping mechanism, a power generation mechanism and a fertilization mechanism, and is characterized in that a leakage net is arranged in the middle of the ditch channel and used for blocking part of sundries, a conveying belt is arranged on the ditch channel and used for conveying garbage into a garbage can, the garbage can is arranged on the side face of the ditch channel and used for collecting the garbage, the garbage dumping mechanism is installed in the middle of the ditch channel, the garbage dumping mechanism achieves the functions of bringing the garbage out of water and preventing water from flowing, the power generation mechanism is installed in the middle of the ditch channel and achieves the function of generating power through water flow, and the fertilizing mechanism is installed in the middle of the ditch channel and realizes the functions of stirring the fertilizer and spraying the fertilizer at a constant speed according to the water flow speed.

Owner:全世启

Automatic quantitative filling device for dairy products

InactiveCN112573466AAutomatic quantitative filling reachesQuantitative filling reachesLiquid materialLiquid bottlingEngineeringMechanical engineering

The invention relates to the technical field of dairy product processing, and discloses an automatic quantitative filling device for dairy products. The automatic quantitative filling device comprisesa shell, wherein a first clamping tooth is sleeved with the shell, a spherical needle valve is fixedly connected to the lower end of the first clamping tooth, a driving gear is in engaged connectionto the exterior of the first clamping tooth, the exterior of the driving gear is in engaged connection with a second clamping tooth, the lower end of a supporting rod is fixedly connected with a threaded lead screw, the threaded lead screw is sleeved with a threaded sliding block, the left side of an upper-layer clamping tooth is fixedly connected with a clamping plate, the lower end of an upper-layer clamping plate is movably connected with a triggering device, a discharging port is formed in the lower end of the shell, a backflow pipe is arranged on the left side of the discharging port, anda backflow preventing device is fixedly connected to the interior of the upper end of the backflow pipe. The device has the advantages that quantitative filling can be carried out in the filling process, and meanwhile, work automation is achieved, the work efficiency is improved, and the dairy products cannot be wasted.

Owner:宋雯雯

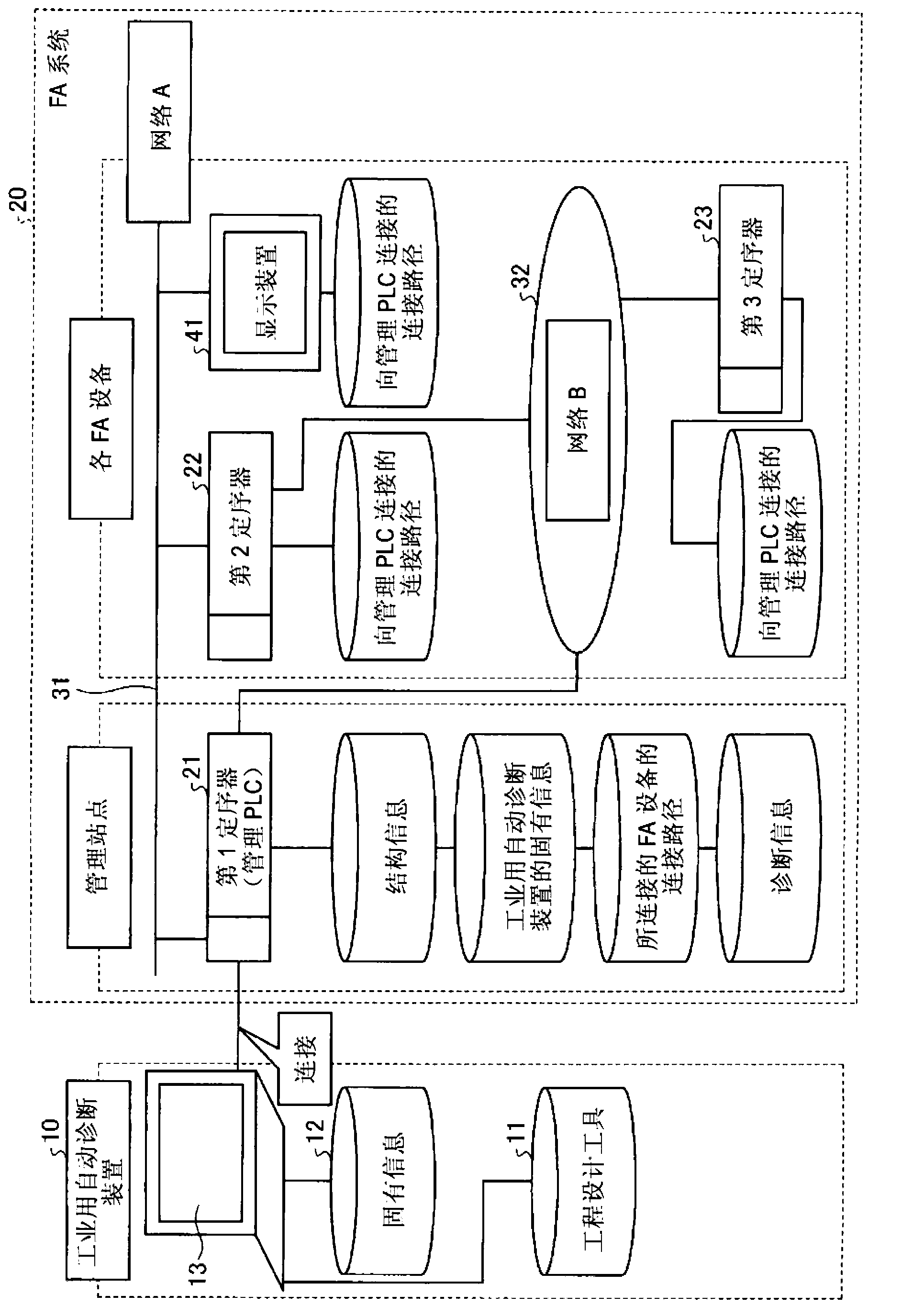

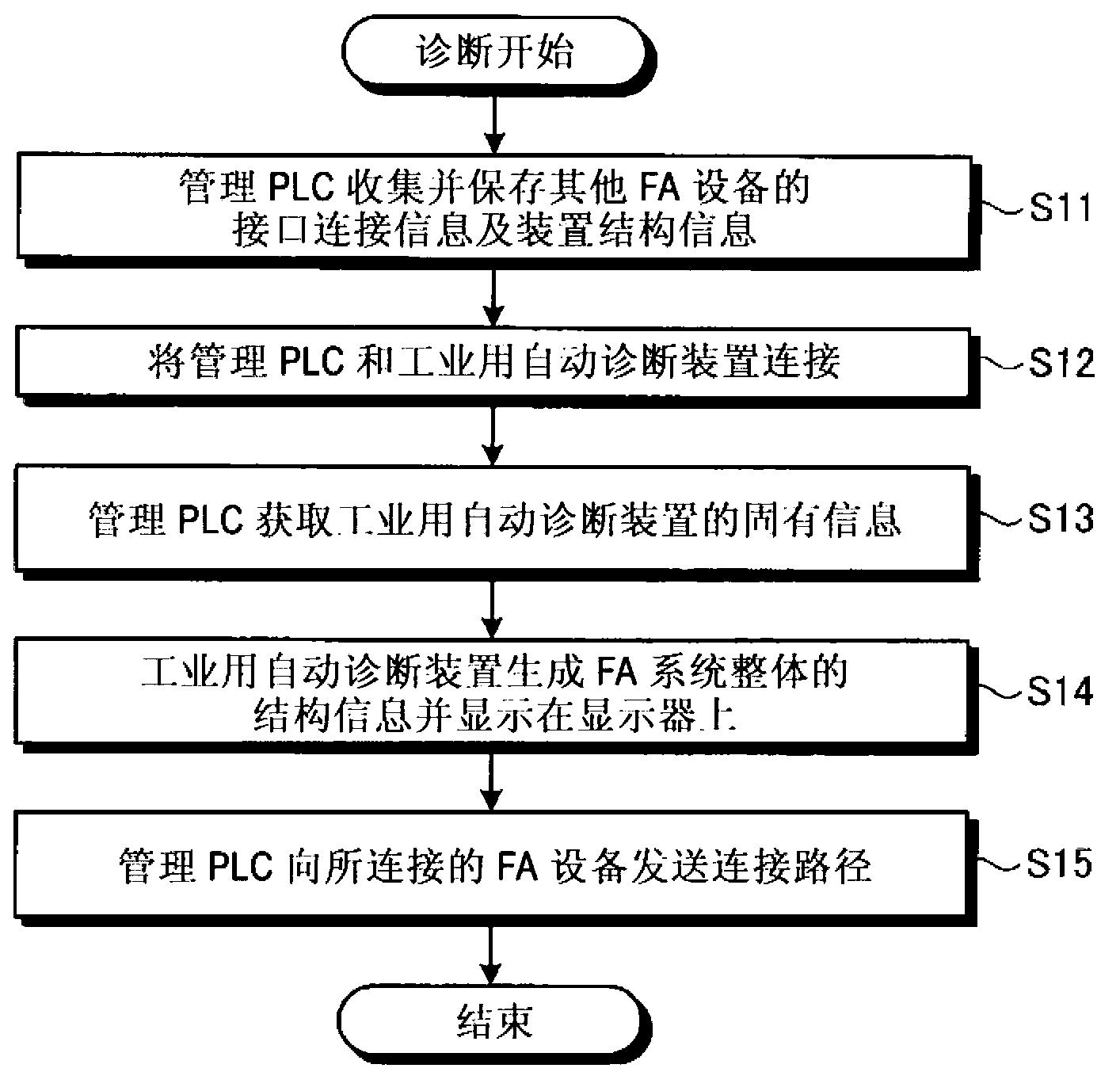

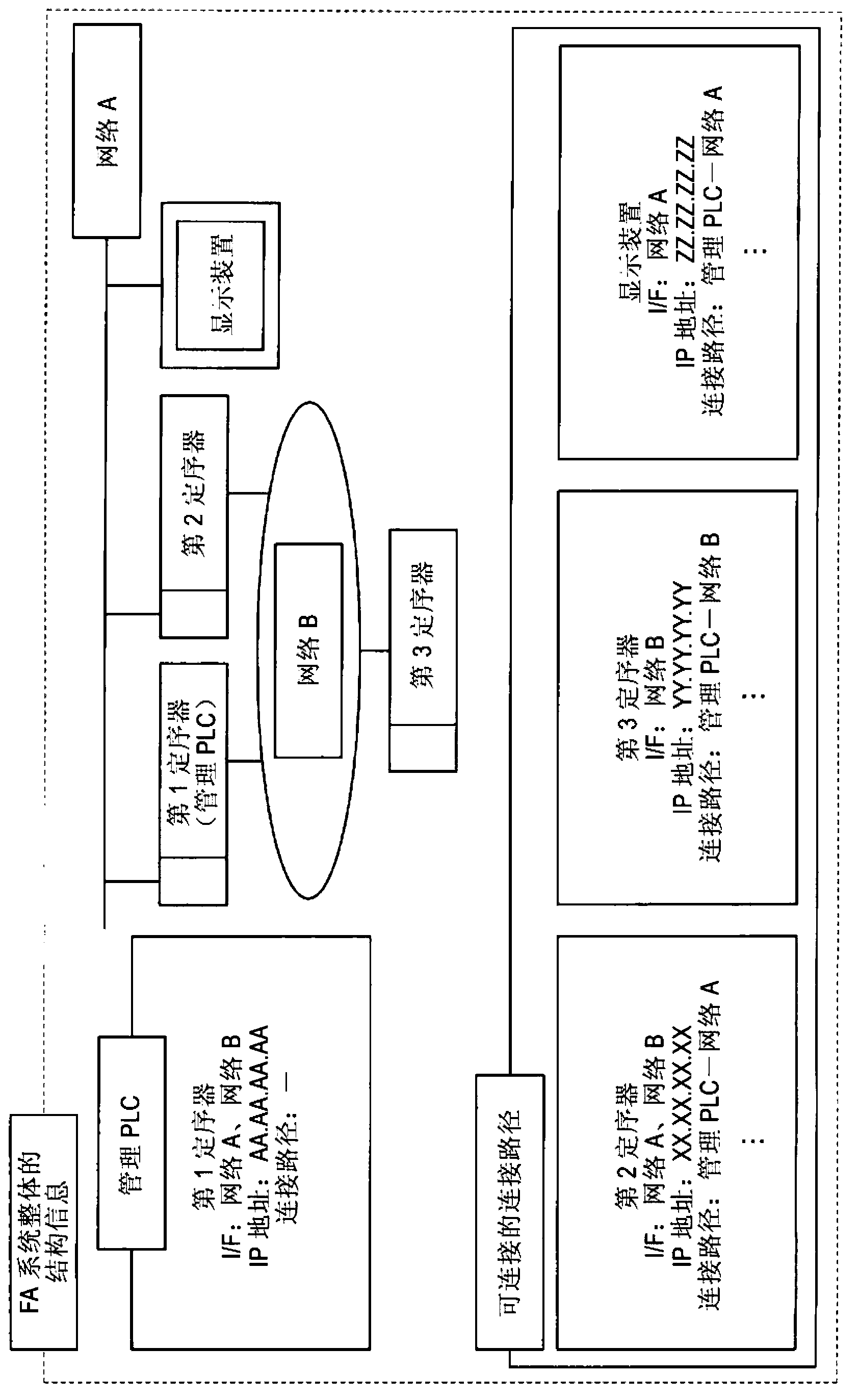

Industrial self-iagnostic device

InactiveCN103250110ARealize the effect of automationProgramme controlElectrical testingEngineering toolEmbedded system

An industrial automatic-diagnostic device connected to an FA system in which a plurality of FA devices are connected to each other, the industrial automatic-diagnostic device includes: an engineering tool; and a display unit. Based on interface connection information and device configuration information of a corresponding FA device held by each of the FA devices, the engineering tool creates overall configuration information of the FA system and displays an overall configuration of the FA system on the display unit based on the overall configuration information. When an abnormality occurs in the FA device, diagnosis information about an abnormal part self-diagnosed by the FA device and abnormality contents with respect to the abnormality occurred in a corresponding abnormal part is obtained. Based on the obtained diagnosis information, occurrence of an abnormality is displayed in an abnormal part in an overall configuration of the FA system displayed on the display unit.

Owner:MITSUBISHI ELECTRIC CORP

Clamping device for sheet metal machining

InactiveCN112372539AGet rid of the inconvenience of clampingRealize the effect of automationWork holdersMechanical measuring arrangementsMetal machiningEngineering

The invention relates to the technical field of sheet metal machining, in particular to a clamping device for sheet metal machining. A base plate, a machining table and clamping plates symmetrically and slidably mounted on two sides of the machining table are included, a water tank is arranged under the base plate, and the machining table is fixedly mounted on the water tank. A first telescopic rod penetrating through the machining table is connected between the base plate and the water tank, the output end of the first telescopic rod is sleeved with a spring, two tubular columns are symmetrically arranged on the two sides of the water tank and communicate with the water tank, the water tank is filled with an aqueous solution, and casing pipes are symmetrically and fixedly connected to thetwo sides of the base plate. The casing pipes are sleeved with the tubular columns in a sliding mode, and a piston is installed in each tubular column in a sliding mode. By the manner of arranging alinkage structure, power is provided through the gravity of sheet metal, so that the clamping plates can automatically move, the width of the sheet metal is measured in real time through a measuring mechanism and fed back to a triggering mechanism, and then the sheet metal is accurately and stably clamped.

Owner:陈武

A spray device suitable for flue gas purification tower

ActiveCN112843991BRealize the effect of automationNo action requiredGas treatmentUsing liquid separation agentThermodynamicsFlue gas

Owner:利晟(杭州)科技有限公司

Soil material separator for argil batch packaging

ActiveCN112356235ASave human effortImprove work efficiencyWrapping material feeding apparatusWrapper folding/bending apparatusBiologySoil science

The invention relates to a soil material separator, in particular to a soil material separator for argil batch packaging. Through the provided soil material separator for argil batch packaging, automatic extrusion forming of argil can be achieved, and the packaged argil can be taken out. The provided soil material separator for argil batch packaging comprises a base, an operation table, a mountingframe, a discharging mechanism, a charging mechanism and an intermittent pushing mechanism. The operation table is connected between the tops of the base. One side of the operation table is connectedwith the mounting frame. One side of the operation table is connected with the discharging mechanism. The operation table is connected with the charging mechanism. The intermittent pushing mechanismis connected between the mounting frame and the discharging mechanism. An extrusion mechanism is connected between an extrusion mechanism mounting frame and the intermittent pushing mechanism. Throughcooperation of the discharging mechanism, the charging mechanism, the intermittent pushing mechanism and the extrusion mechanism, the argil can be automatically extruded downwards, meanwhile, the argil moves leftwards after extrusion forming, the argil is collected, and therefore an automatic effect can be achieved.

Owner:山东连环机械科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com