Automatic heating device and automatic heating method for seawater seedling culture pond

A technology for automatic heating and nursery ponds, applied in fish farming, applications, animal husbandry, etc., can solve problems such as increasing operating costs of enterprises, increasing energy consumption, and misoperation of operators, reducing production costs and management costs, eliminating Misuse behavior and the effect of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

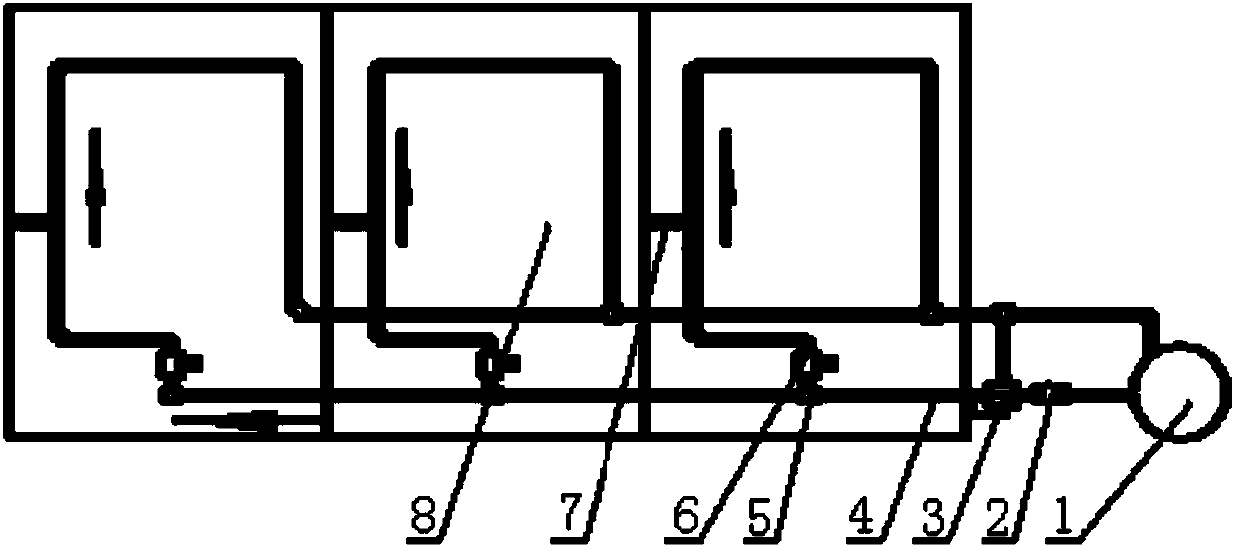

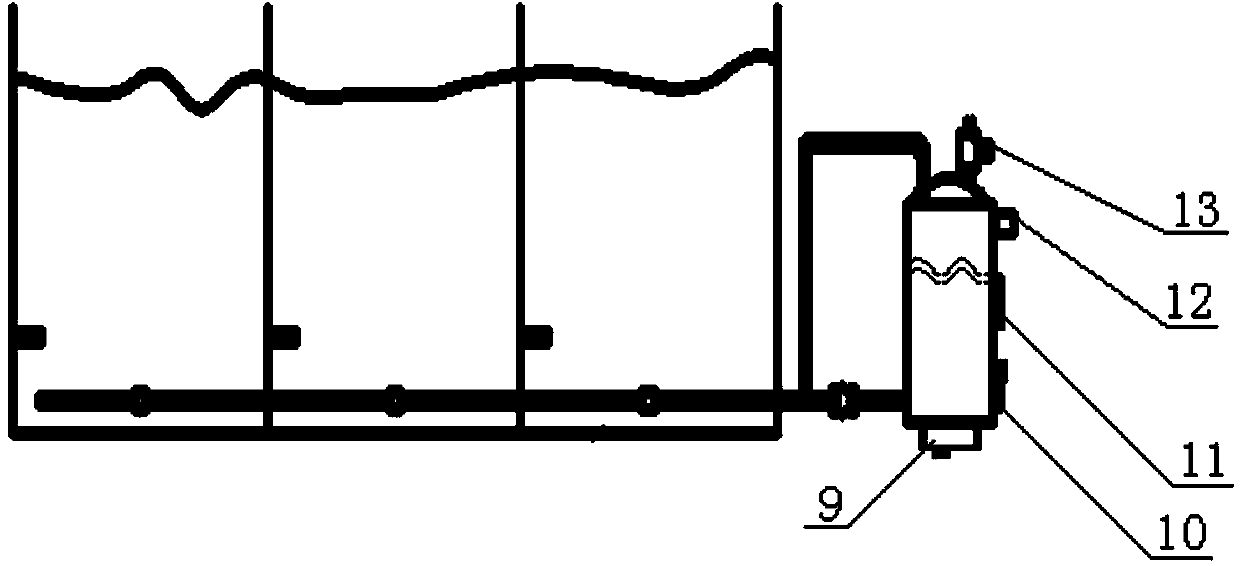

[0028] Such as Figure 1-2 As shown, the present invention provides an automatic heating device for a seawater seedling pond, including a seedling pond 8, a water inlet pipe 4 is installed inside the seedling pond 8, and a pressure hot water delivery pump 2 and a pressure reducing valve are installed on the water inlet pipe 4 3 and tee 5, the water inlet pipe 4 is communicated with the return pipe, the ends of the return pipe and the water inlet pipe 4 are respectively communicated with the water storage device 1, and a temperature relay 7 is installed between the middle part of the water inlet pipe 4 and the seedling pond 8; An electromagnetic control valve 6 is installed above the tee 5; a controllable electric heater 9 for heating the water storage 1 is installed under the water storage 1, and a temperature-controlled safety valve is installed on the side of the water storage 1 12. A temperature sensor 11, a water level controller 10, and an electromagnetic water injection ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com