Automatic welding working platform of steel structure

A technology of automatic welding and working platform, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of large volume and weight of steel structure pipes, time-consuming, overturning, and large impact force of movement, etc. To achieve the effect of providing production efficiency and saving manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The following description includes sample systems, methods, and devices that embody various elements of the disclosure. It should be understood, however, that the described disclosure may be embodied in many forms in addition to those described herein.

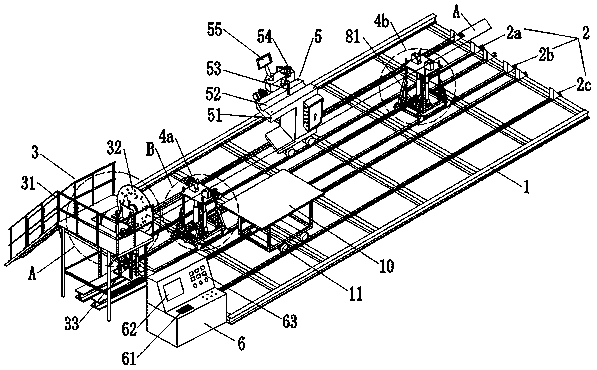

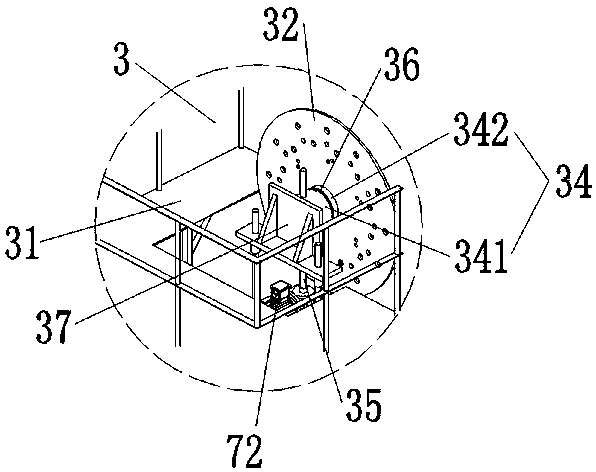

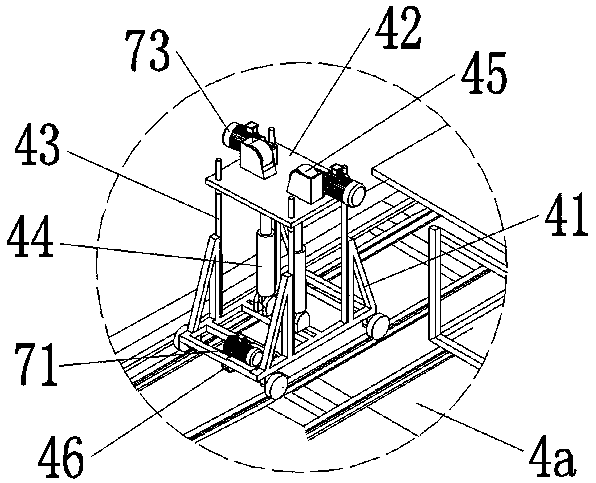

[0027] Reference manual attached figure 1 As shown, it is the overall three-dimensional design drawing of the present disclosure. The steel structure automatic welding work platform includes a platform base 1, a rotary indexing mechanism 3, a console 6 and a pulley track 2 installed on the platform base 1. The pulley track 2 is equipped with a supporting mechanism 4, a welding machine 5 and a tool console 10, and the rotary indexing mechanism 3 and the supporting mechanism 4 are all equipped with servo motors, and the servo motors control the vertical lifting and lowering of the rotary indexing mechanism 3 respectively. The horizontal movement of the support mechanism 4; the servo motor also controls the rotation of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com