Soil material separator for argil batch packaging

A separator and soil material technology, which is applied in ceramic molding machines, packaging material feeding devices, packaging, etc., can solve the problems of troublesome manual operation and difficulty in equal distribution of materials, so as to improve work efficiency, reduce errors and save manpower. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

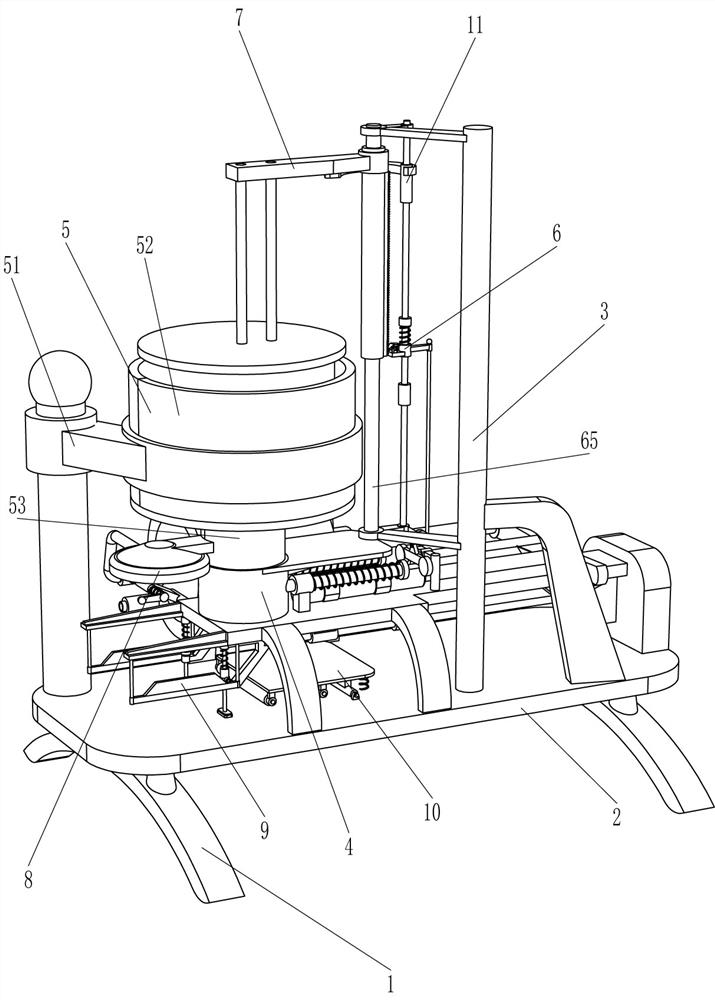

[0091] A soil material separator for batch packing of pottery clay, such as figure 1 As shown, it includes a base 1, an operating table 2, a mounting frame 3, a discharge mechanism 4, a charging mechanism 5, an intermittent pushing mechanism 6 and an extruding mechanism 7. An operating table 2 is connected between the top of the base 1, and the operating table 2 The right front side is connected with a mounting frame 3, the left side of the console 2 is connected with a discharge mechanism 4, the left rear side of the console 2 is connected with a charging mechanism 5, and an intermittent push mechanism 6 is connected between the mounting frame 3 and the discharge mechanism 4. A pressing mechanism 7 is connected between the installation frame 3 and the intermittent pushing mechanism 6 .

[0092] When people need to pack the pottery clay in batches, they first pour the pottery clay into the charging mechanism 5, start the discharge mechanism 4, and the discharge mechanism 4 dri...

Embodiment 2

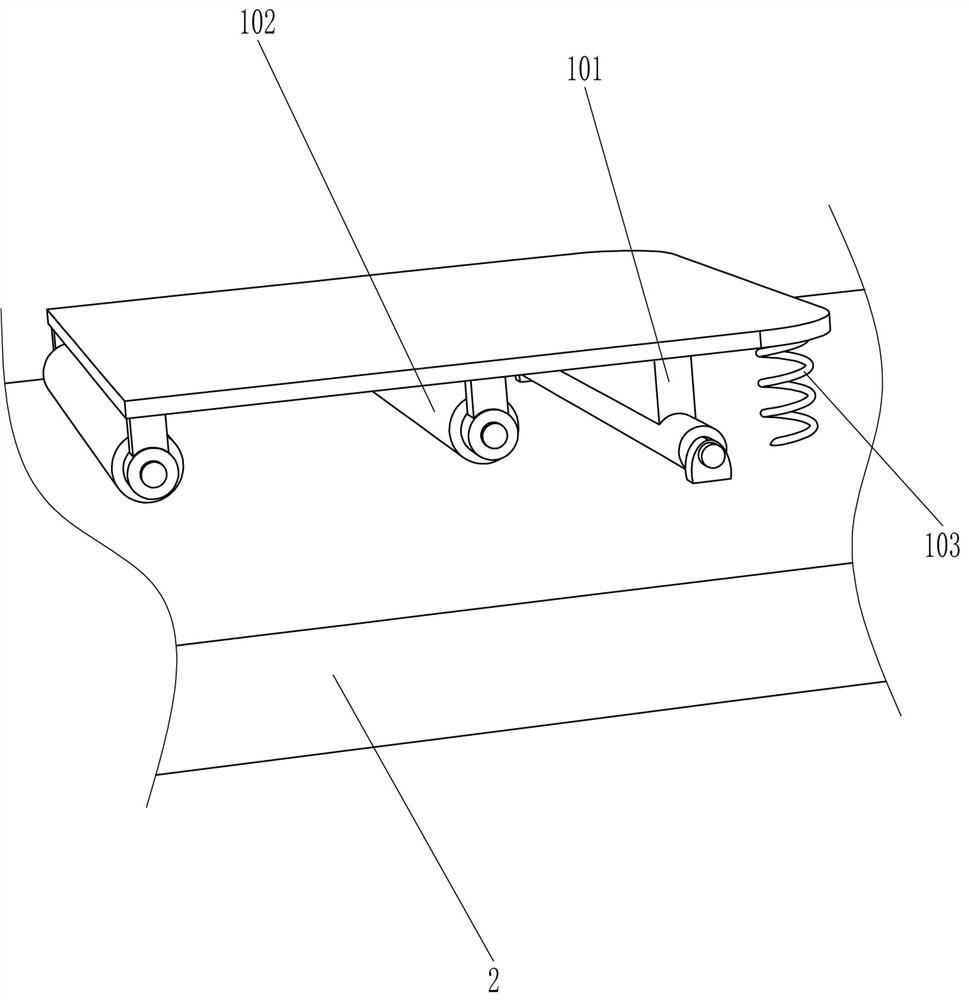

[0094] On the basis of Example 1, such as figure 1 , figure 2 and Figure 4 As shown, the discharge mechanism 4 includes a horizontal plate 41, a first guide sleeve 42, a first guide rod 43, a discharge ring 44, a first spring 45, a baffle plate 46, an electric push rod 47, a connection, a second guide rod 49. The second guide sleeve 410 and the contact plate 411, the top of the console 2 is connected with a horizontal plate 41, the top of the left side of the horizontal plate 41 is connected with the first guide sleeve 42 on the front and rear sides, and the first guide sleeve 42 is slidingly connected There is a first guide rod 43, a discharge ring 44 is connected between the left side of the first guide rod 43, a first spring 45 is connected between the right side of the first guide sleeve 42 and the first guide rod 43, and the first spring 45 Set on the outside of the first guide rod 43, the upper right side of the discharge ring 44 is connected with a baffle 46, the le...

Embodiment 3

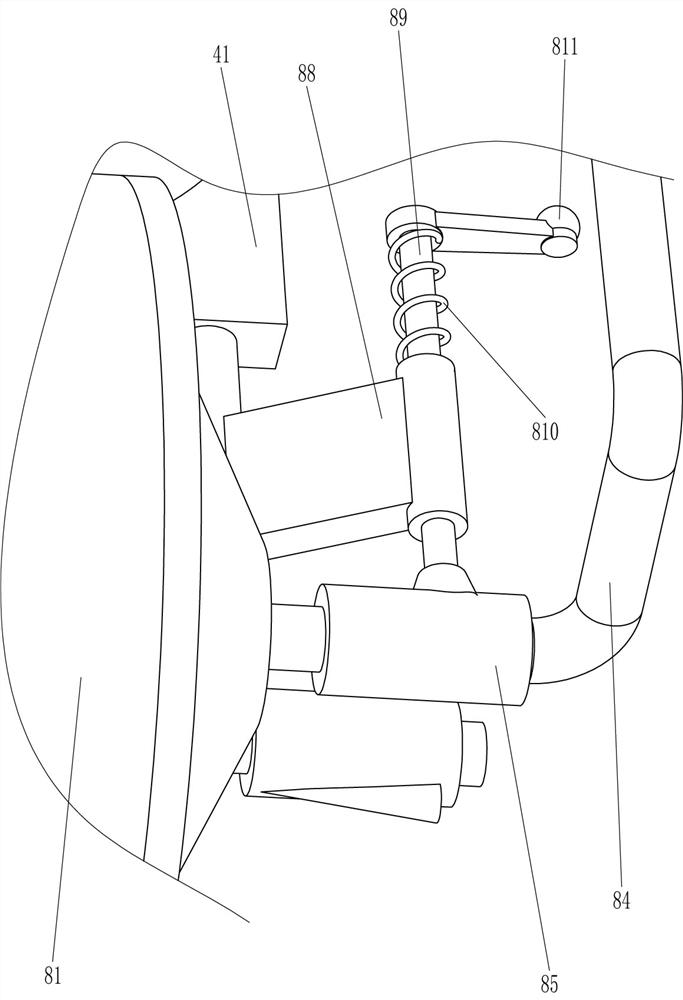

[0099] On the basis of Example 2, such as figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 and Figure 9 As shown, the intermittent pushing mechanism 6 includes a stay cord 61, a guide wheel 62, a fixed mount 63, a first guide rod 64, a second guide rod 65, a guide ring 66, a stabilizer 67, a pawl 68, a second spring 69, Helical rack 610 and the 3rd spring 611, mounting frame 3 bottoms are connected with fixed mount 63, and fixed mount 63 rear portion right side rotation type is connected with lead wheel 62, and fixed mount 63 left top is connected with second guide bar 65, fixes A first guide rod 64 is connected in the middle of the rear side of the frame 63, and a guide ring 66 is slidably connected to the first guide rod 64. A stay cord 61 is connected between the right side of the guide ring 66 and the top of the contact plate 411, and the stay cord 61 bypasses the Guide wheel 62, guide ring 66 left side is connected with stabilizing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com