Three-coordinate measuring method and device for workpiece, equipment and storage medium

A technology of three-coordinate measurement and measurement method, applied in the field of measurement, can solve the problems of reducing the universality of automatic detection, manual alignment, time-consuming and labor-intensive, etc., and achieve the effect of realizing the effect of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

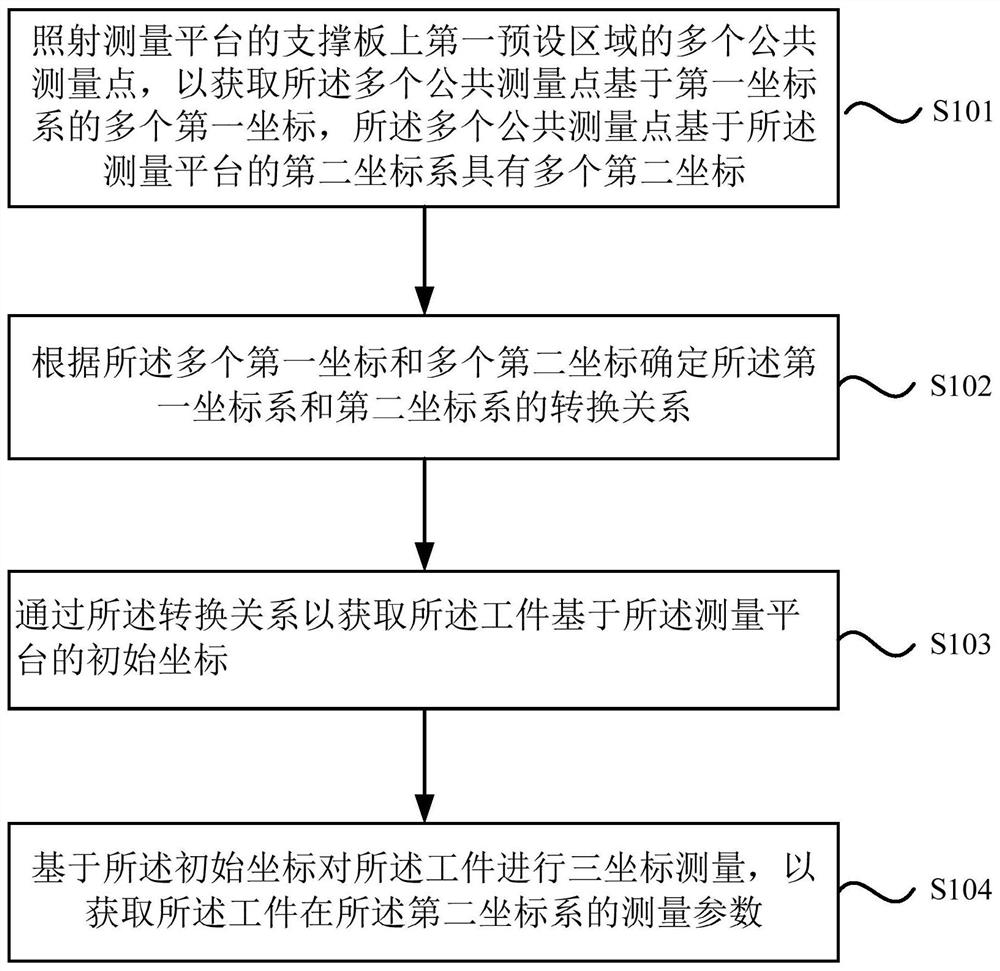

[0033] like figure 1 As shown, Embodiment 1 of the present invention provides a three-coordinate measurement method of a workpiece, and the three-coordinate measurement method of the workpiece includes:

[0034] S101. Irradiate a plurality of public measurement points in the first preset area on the support plate of the measurement platform, so as to obtain a plurality of first coordinates of the plurality of public measurement points based on the first coordinate system, and the plurality of public measurement points are based on The second coordinate system of the measurement platform has a plurality of second coordinates.

[0035] In this embodiment, the measuring platform is a three-coordinate measuring machine, and the supporting plate of the measuring platform is irradiated by a laser projection system. A first preset area may be preset on the support plate of the three-coordinate measuring machine, and the area of the first preset area is smaller than that of the sup...

Embodiment 2

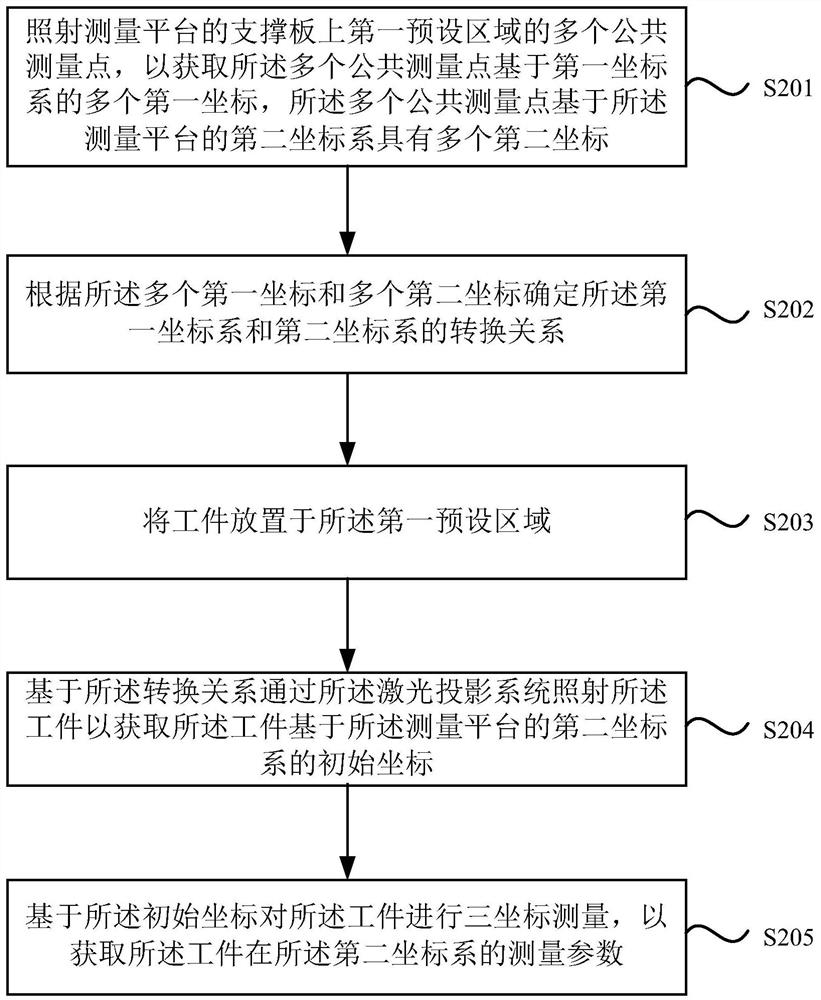

[0044] like figure 2 As shown, Embodiment 2 of the present invention provides a three-coordinate measurement method of a workpiece. Embodiment 2 of the present invention is based on the solution of Embodiment 1 of the present invention, and has been optimized and improved. The three-coordinate measurement method of the workpiece includes:

[0045] S201. Irradiate a plurality of public measurement points in the first preset area on the support plate of the measurement platform, so as to obtain a plurality of first coordinates of the plurality of public measurement points based on the first coordinate system, and the plurality of public measurement points are based on The second coordinate system of the measurement platform has a plurality of second coordinates.

[0046] In this embodiment, the measuring platform is a three-coordinate measuring machine, and the supporting plate of the measuring platform is irradiated by a laser projection system. A first preset area may be pre...

Embodiment 3

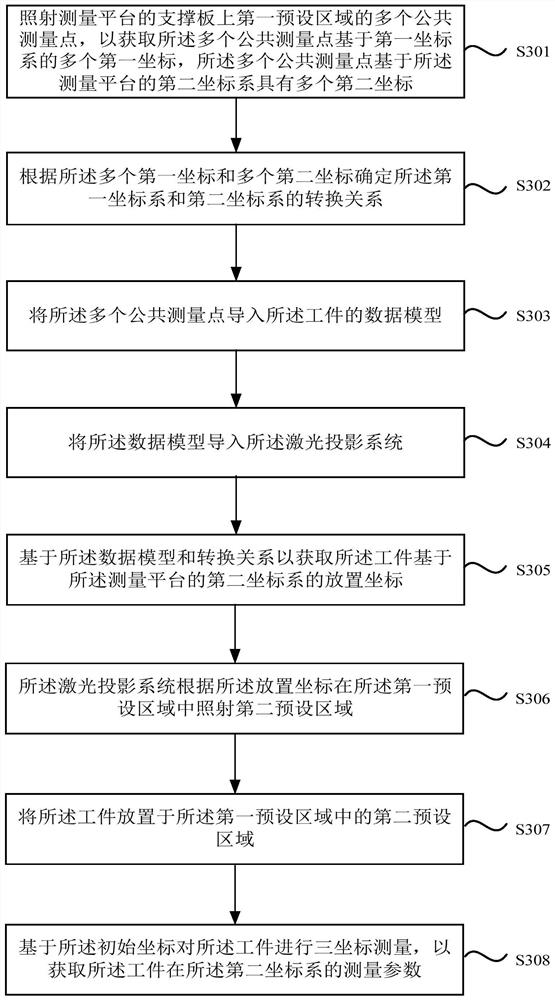

[0056] like image 3 As shown, Embodiment 3 of the present invention provides a three-coordinate measurement method of a workpiece. Embodiment 3 of the present invention is based on the solution of Embodiment 1 of the present invention, and has been optimized and improved. The three-coordinate measurement method of the workpiece includes:

[0057] S301. Irradiate a plurality of common measurement points in the first preset area on the support plate of the measurement platform, so as to obtain a plurality of first coordinates of the plurality of common measurement points based on the first coordinate system, and the plurality of common measurement points are based on The second coordinate system of the measurement platform has a plurality of second coordinates.

[0058] In this embodiment, the measuring platform is a three-coordinate measuring machine, and the supporting plate of the measuring platform is irradiated by a laser projection system. A first preset area may be pres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com