Tea carding machine capable of realizing tea discharge conveniently

A tea straightening machine, a convenient technology, applied in tea processing before extraction, etc., can solve the problems of high labor intensity, accidental injury to personnel, heavy pot, etc., and achieve the effect of reducing labor intensity and avoiding personnel injury

Active Publication Date: 2016-01-20

天津思度工业设计有限公司

View PDF6 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, the tank is relatively heavy, and it requires a lot of labor to turn it over manually, and it is inevitable that accidental injuries will occur.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0012] Below in conjunction with accompanying drawing and embodiment the technical solution of the present invention is further described:

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

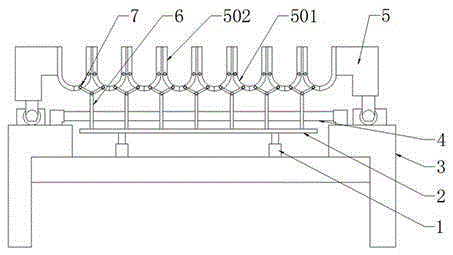

The invention discloses tea production equipment and particularly relates to a tea carding machine capable of realizing tea discharge conveniently. The tea carding machine comprises a rack, a pot rack reciprocating on the rack and a grooved pot mounted on the pot rack, wherein the grooved pot comprises a plurality of U-shaped grooves, each U-shaped groove comprises two side plates and two arc plates hinged to the lower ends of the side plates, and the two arc plates are closed to constitute the bottom of the U-shaped groove; a control mechanism for controlling opening and closing of the arc plates is arranged on the rack and comprises Y-shaped support columns and hydraulic columns connected with lower parts of the Y-shaped support columns, each Y-shaped support column comprises three supports, the three supports of each Y-shaped support column are hinged to the same hinged point, two upward supports of each Y-shaped support column are hinged with two opposite arc plates respectively, and the length sum of the two upward supports is larger than an interval between the adjacent hinged points when the arc plates are in the closed state. When the tea carding machine is used for tea discharge, the arc plates at the bottom of the U-shaped grooves are opened, tea drops on a conveying belt below the arc plates, and accordingly, the tea discharge is realized.

Description

technical field [0001] The invention relates to a tea manufacturing equipment, in particular to a tea straightening machine which can conveniently produce tea. Background technique [0002] In the process of tea processing, there is usually a process of tea shaping, and the formed tea has different shapes such as granules and strips. Among them, tea stripping is an indispensable process in the production of strip tea. At present, the most commonly used tea stripping machine is a traditional single-pot structure, which mainly includes a frame, a pot frame that reciprocates above the frame, and a pot frame that realizes the pot. The driving structure of the reciprocating movement of the frame, the pot frame is installed with a pot, and a heat source device for heating the tea leaves in the pot. When processing needle-shaped tea leaves, put the tea leaves to be processed into the trough of the slitting machine, heat the tea in the trough through the heat source device, and the...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): A23F3/06

Inventor 刘滨

Owner 天津思度工业设计有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com