Follow fixture library device and automatic fixture switching system and method

An accompanying fixture and automatic switching technology, which is applied in auxiliary devices, manufacturing tools, transportation and packaging, etc., can solve the problems of occupying a large area and large storage space, and achieve large usable area, short replacement time and small space occupation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

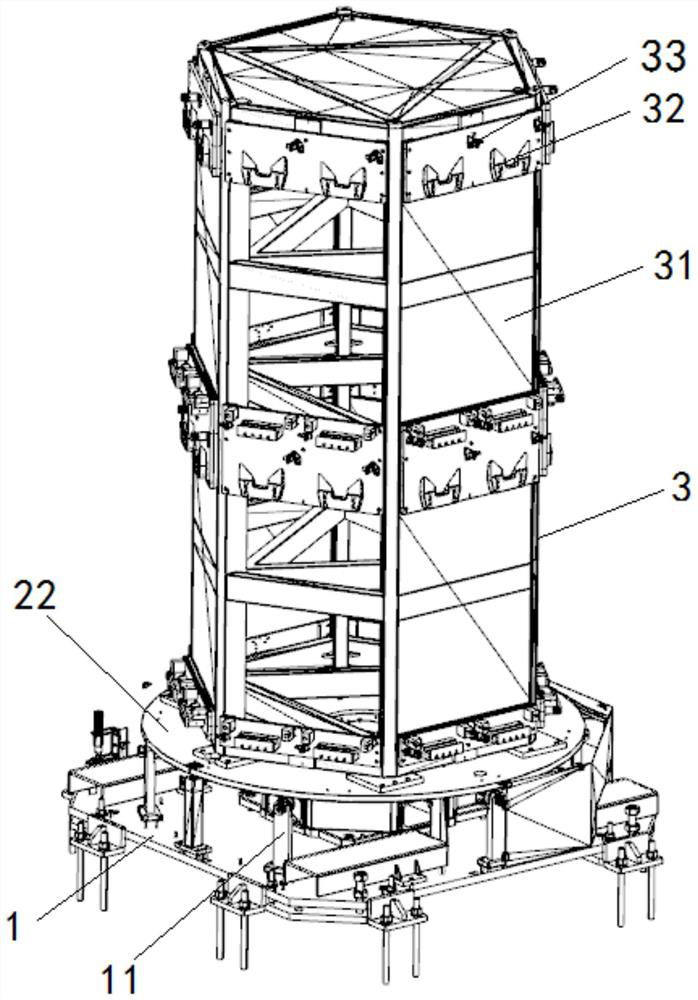

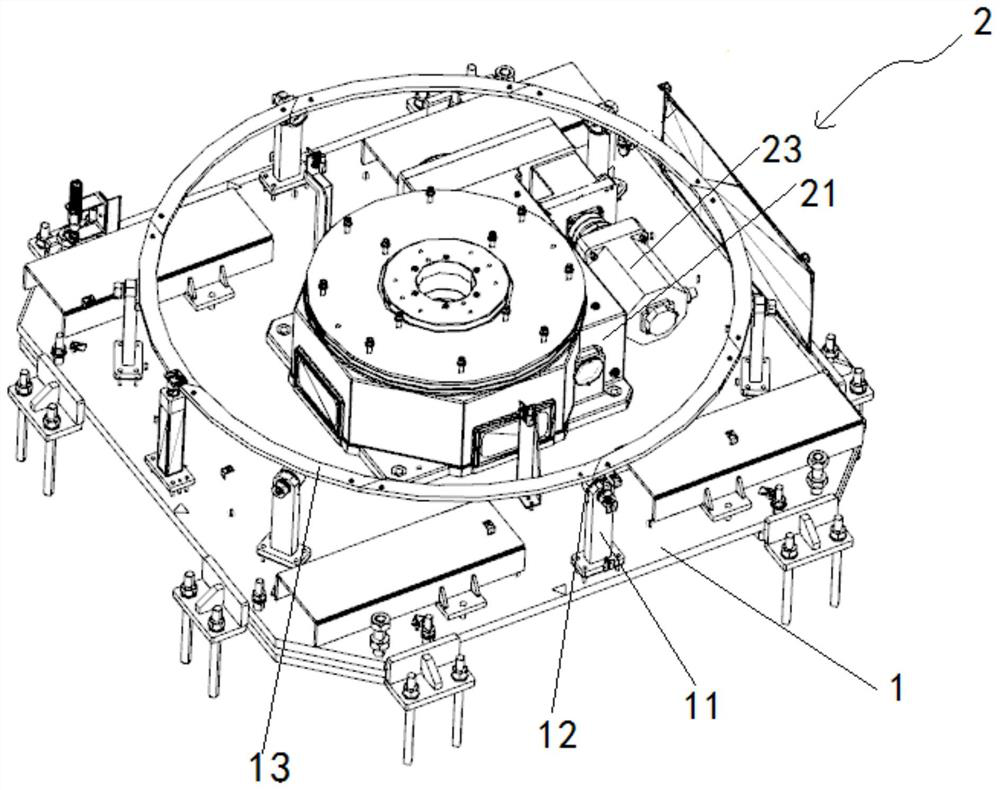

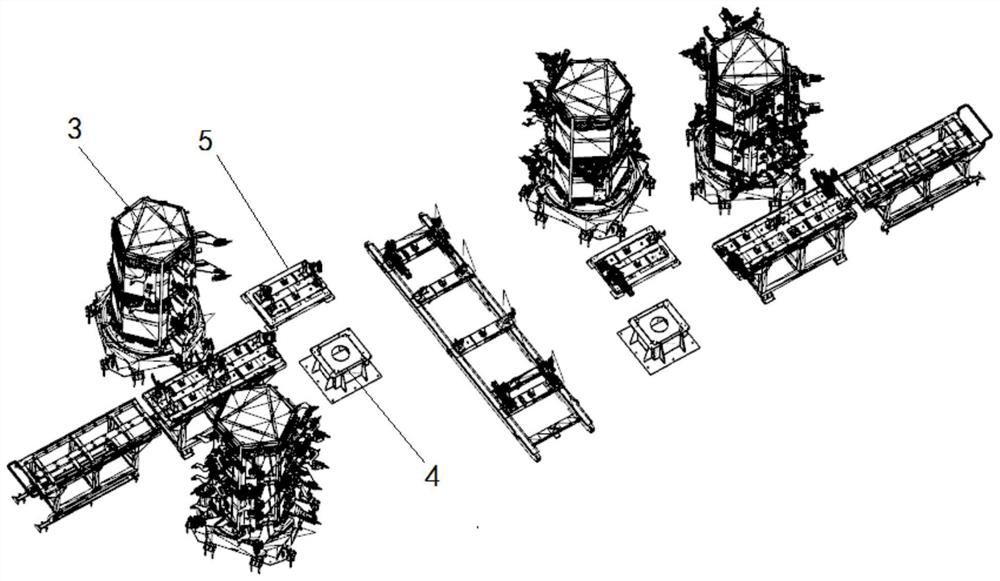

[0029] The following with attached Figure 1 to Figure 2 A pallet library device of the present invention will be further described in detail.

[0030] A kind of accompanying fixture storehouse device of the present invention, please refer to Figure 1 to Figure 2 The relevant figures include a base 1, a rotating mechanism 2 and a columnar placing seat 3. The rotating mechanism 2 is arranged in the center of the base 1, and the columnar placing seat 3 is arranged on the rotating mechanism 2. The rotating mechanism 2 can drive the cylindrical placing seat 3 for 30- Rotation of 360° travel. At least two installation surfaces 31 are provided on the outer peripheral surface of the columnar placement seat 3. For example, the two installation surfaces 31 are arranged oppositely, and the installation surface 31 is provided with a placement assembly 32 for placing assembly fixtures. The number of components 32 corresponds to the number of all jigs of a vehicle on the assembly line. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com