Clamping device

A clamping device and clamping arm technology, applied in the direction of chuck, manufacturing tool, manipulator, etc., can solve the problems of inconvenient use and maintenance, and achieve the effect of easy use and maintenance and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

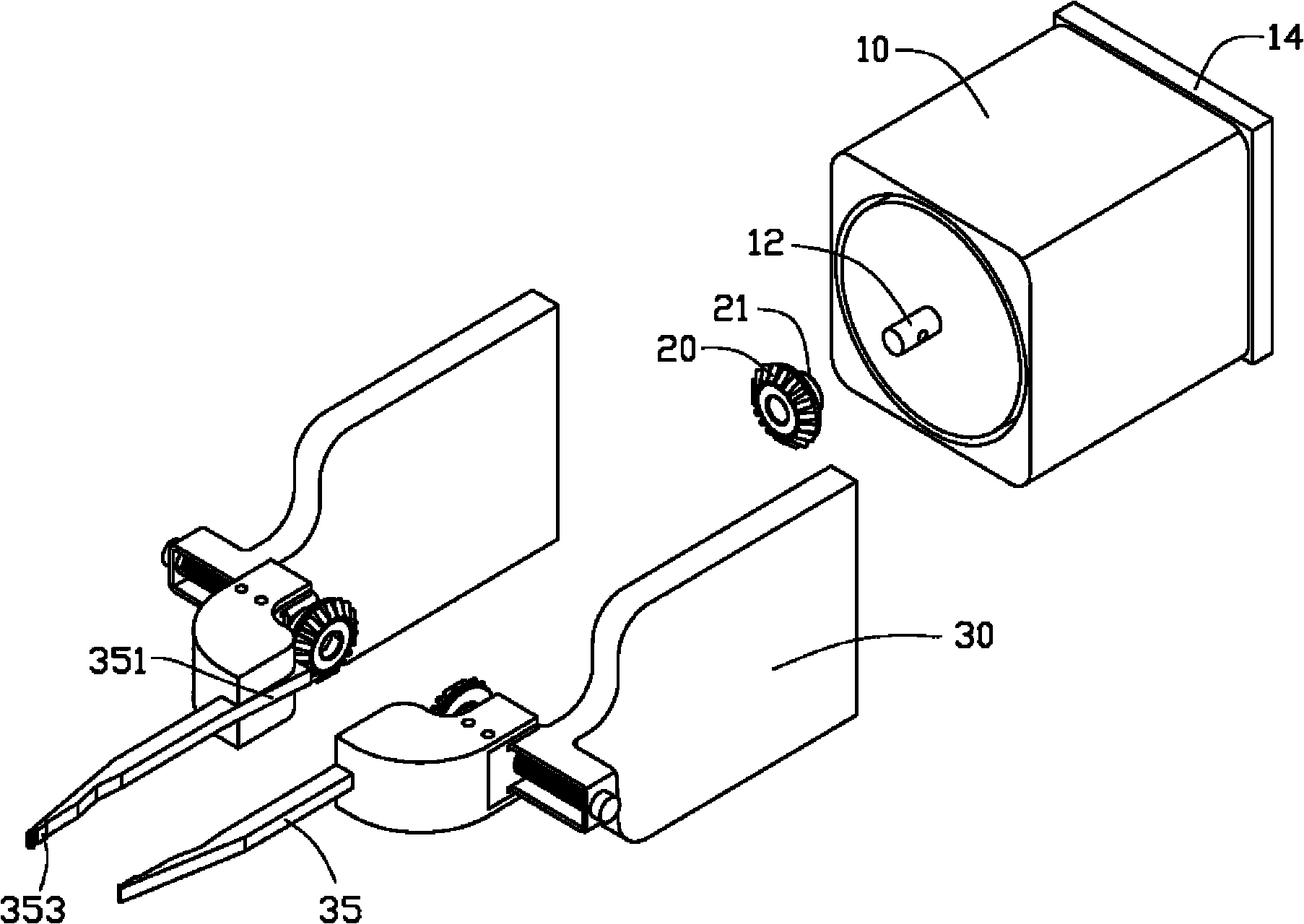

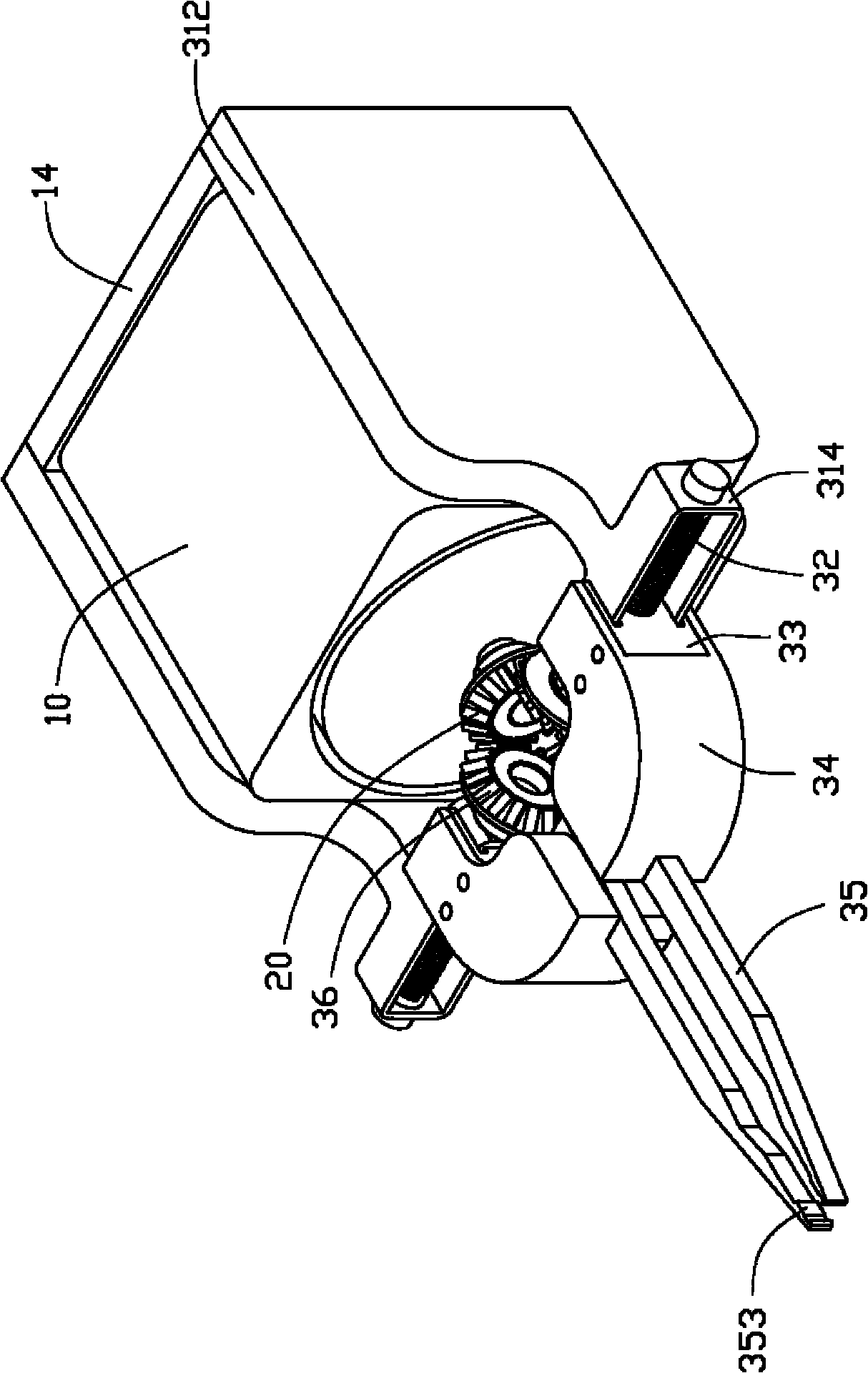

[0011] Please refer to figure 1 , The preferred embodiment of the clamping device of the present invention includes a motor 10 , a driving gear 20 and a pair of clamping bodies 30 .

[0012] A shaft 12 protrudes from a first end of the motor 10 . The second end of the motor 10 (the end away from the first end) is provided with a fixing base 14 .

[0013] The driving gear 20 is a bevel gear, with a mounting portion 21 protruding from its middle toward one end, and the mounting portion 21 is provided with a mounting hole (not shown) along the axial direction.

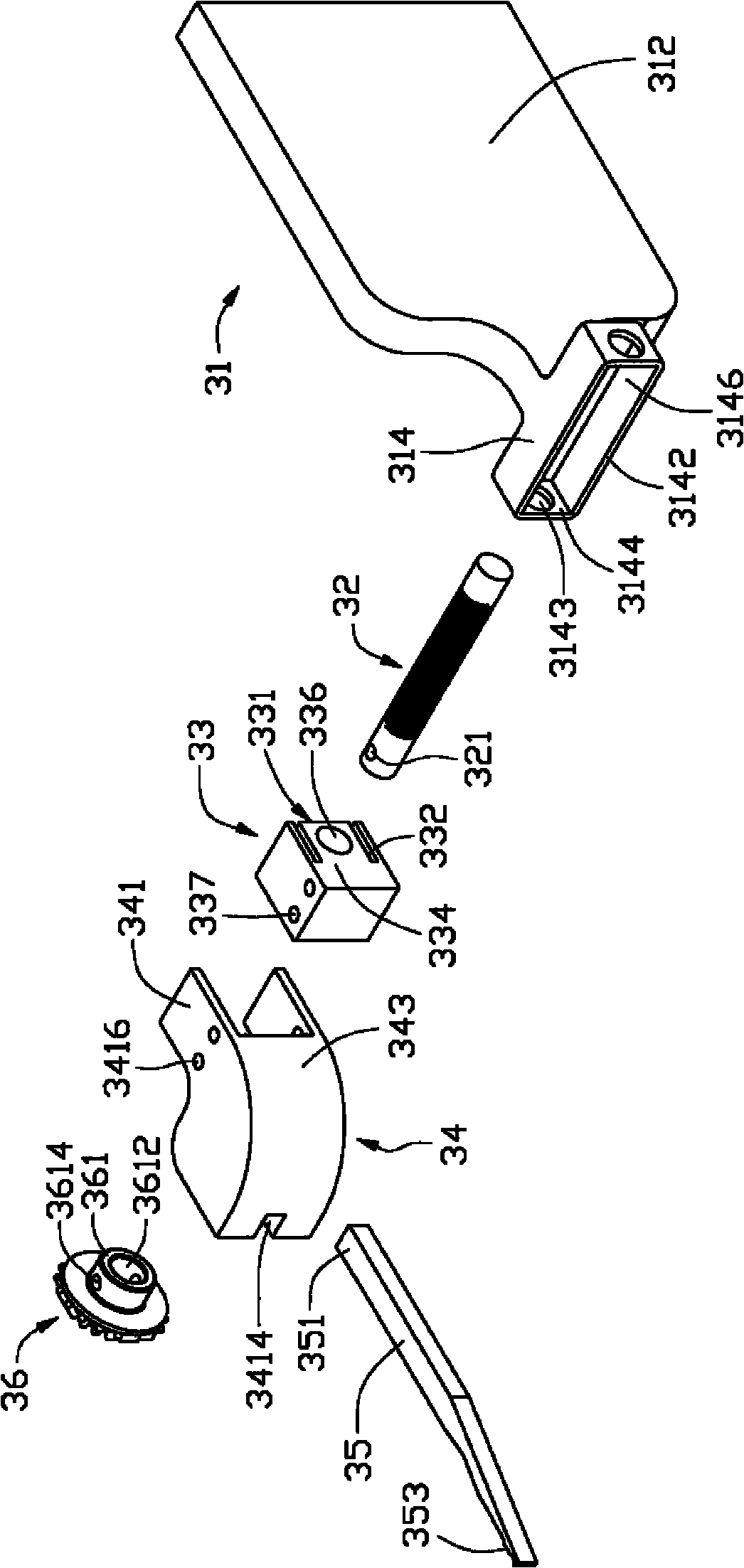

[0014] Please also see figure 2 , the structure and assembly method of the pair of clamping bodies 30 are the same, and only one of them will be taken as an example below for illustration. The clamping body 30 includes a support frame 31 , a screw 32 , a slider 33 , a connecting piece 34 , a clamping arm 35 and a driven gear 36 . The supporting frame 31 includes a side plate 312 and a pivot portion 314 connected to o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com