Multi-shaft double-sided automatic cleaning machine for lenses

An automatic cleaning machine and lens technology, applied in the direction of cleaning flexible objects, cleaning methods and utensils, cleaning methods using tools, etc., can solve the problems of high price, high cost, complicated process, etc., and achieve reduced production costs and a high degree of automation , Improve the effect of cleaning quality and work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

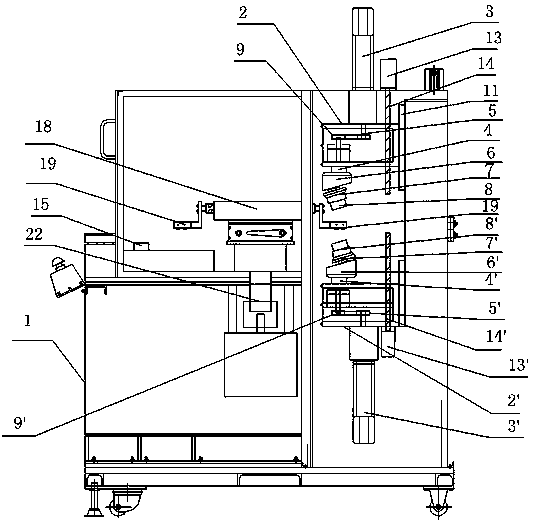

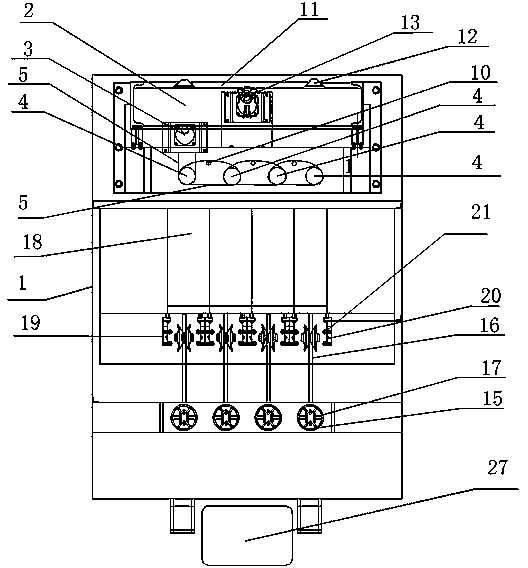

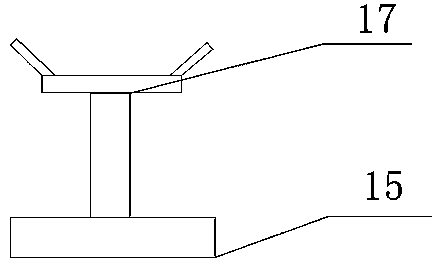

[0022] Such as figure 1 , figure 2 , image 3 The shown multi-axis double-sided automatic lens cleaning machine includes a frame 1, on which a lens delivery device for supplying lenses is arranged, and the lens delivery device includes a material box 15 and a sliding groove 16, and the material Box 15 is arranged on the sliding groove 16, and material box 15 can slide on sliding groove 16, and liftable pallet 17 is set on material box 15, when material box 15 slides to the end of sliding groove 16, pallet 17 can be moved up and down. Lifting movement, used to hold up the lens and retract the lens. A lens clamping device is arranged at the end of the lens delivery device, and the lens clamping device includes a clamping platform 18 and a clamping body 19 arranged on the clamping platform 18. The surface of the clamping body 19 is provided with a groove 20. Rollers 21 are arranged at both ends of the groove 20, and the clamp body 19 is clamped or released by the clamping cyl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com