Double-ridge peanut combined harvester

A technology for combine harvesters and peanuts, which is applied to digging harvesters, harvesters, agricultural machinery and implements, etc., and can solve problems such as doubling costs, high center of gravity, and complex internal structures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0077] The present invention will be further described below in conjunction with specific examples.

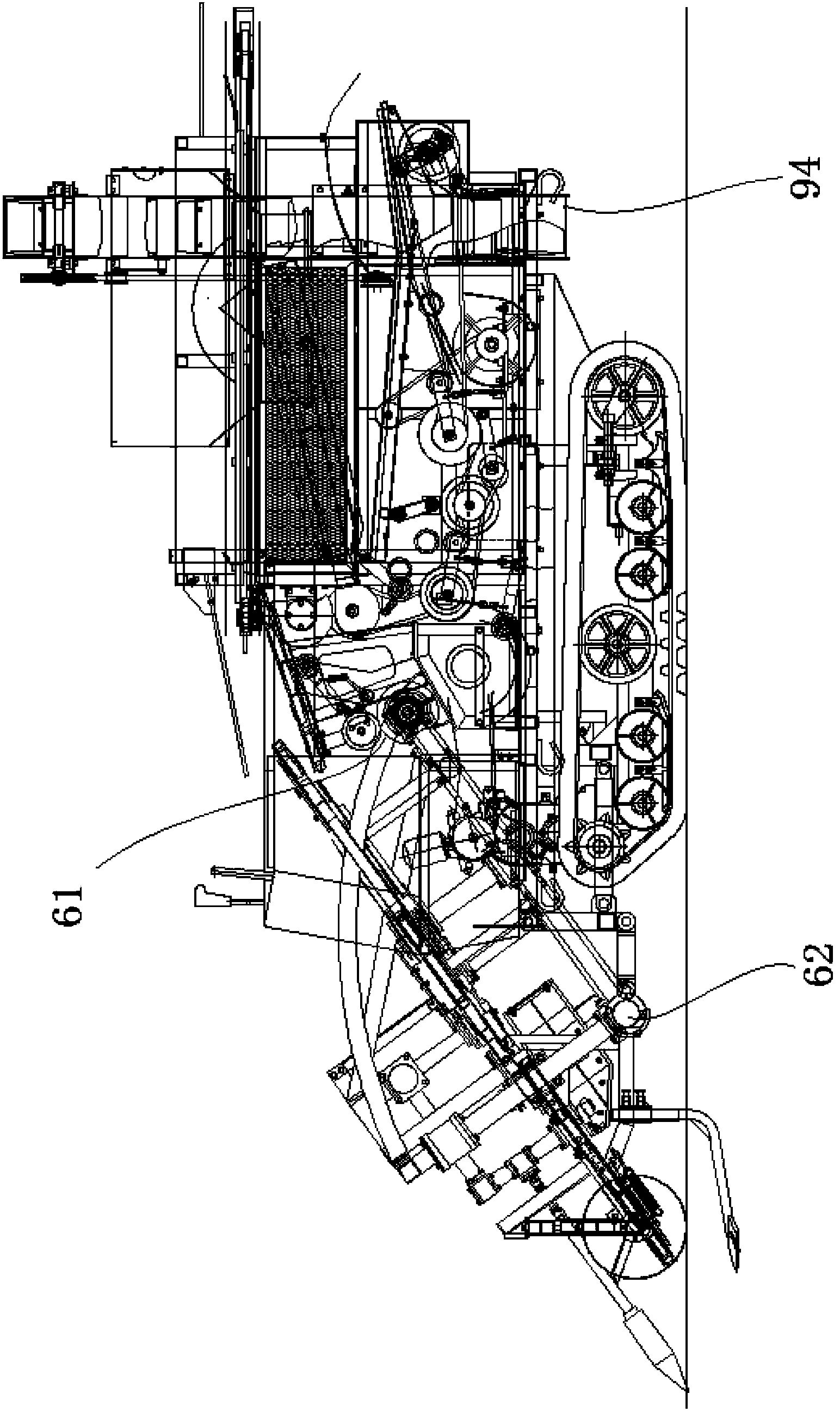

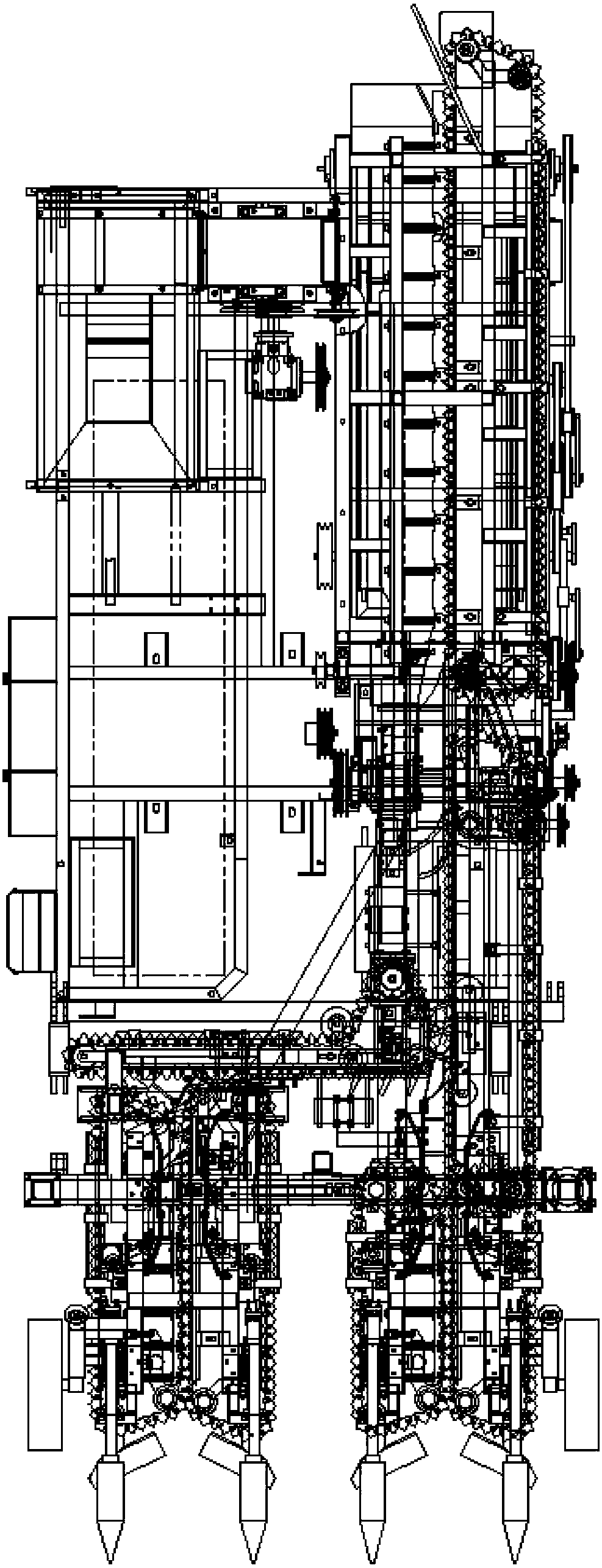

[0078] figure 1 with 2 It shows the overall structure of the two-row peanut combine harvester, including the chassis. The harvesting platform, the transition clamping conveying device, and the rear frame assembly are fixedly arranged front and rear on the chassis, and the rear portion of the rear frame assembly is also connected with the elevator 94.

[0079] Let the forward direction of the two-row peanut combine harvester be the front, and the direction perpendicular to it horizontally be the horizontal direction.

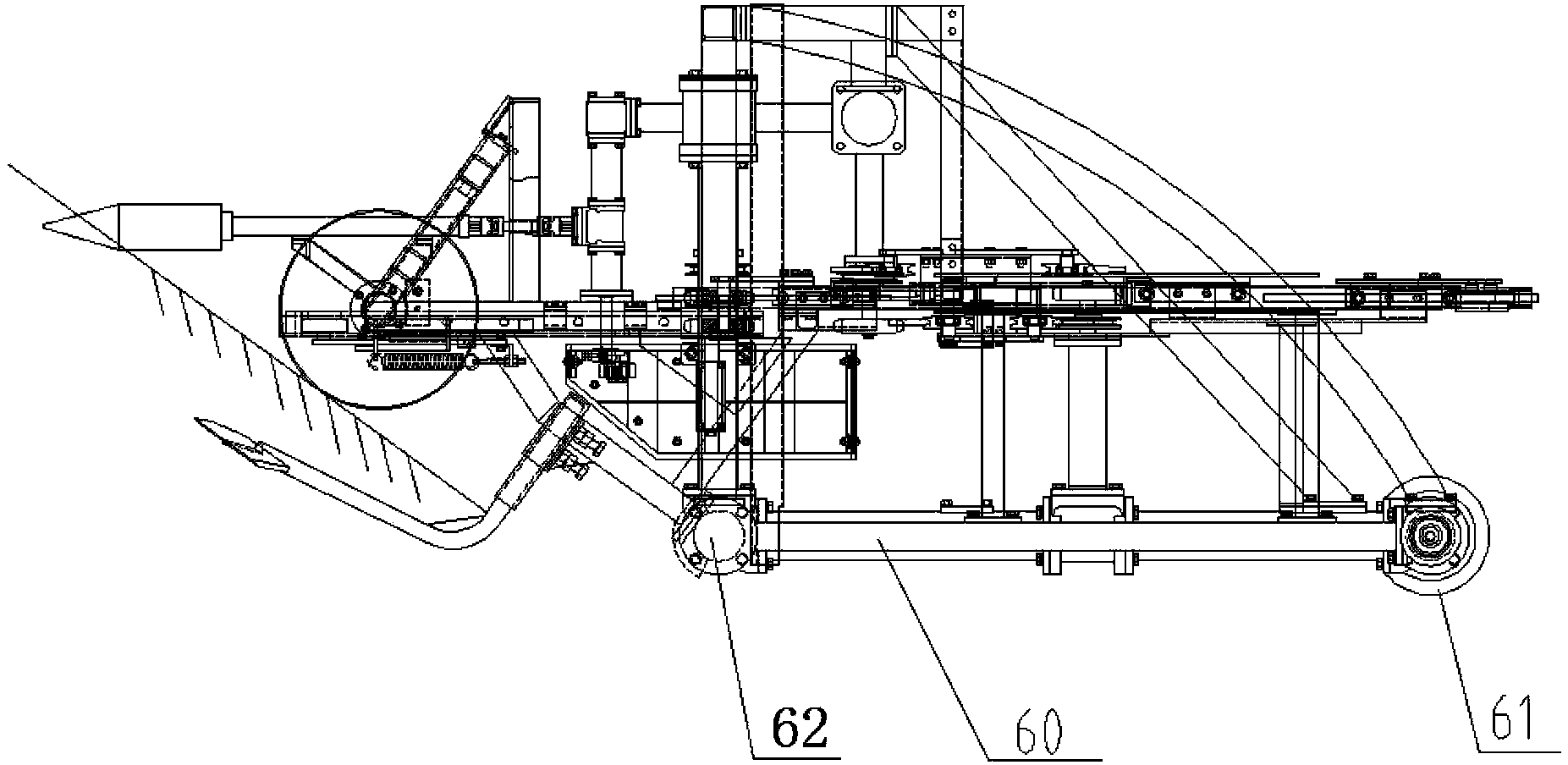

[0080] The following is a detailed description of the harvesting platform part:

[0081] see Figure 1-Figure 4 The frame 60 of the harvesting platform of the combined peanut harvester is fixed on the fuselage of the combined peanut harvester through the upper main beam 61 of the horizontal configuration, and the harvesting platform can rotate around the uppe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com