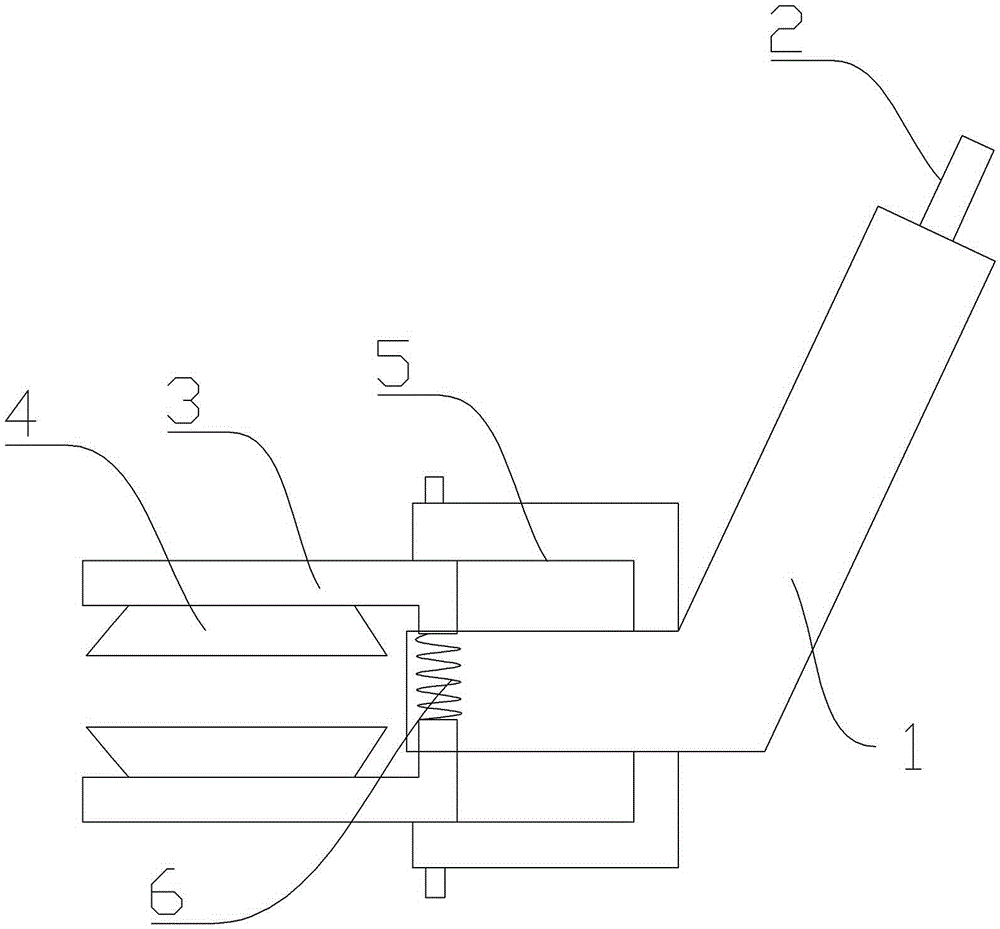

Glass transfer clamping equipment

A technology for clamping equipment and glass, which is applied in glass manufacturing equipment, glass transportation equipment, manufacturing tools, etc., can solve the problems of easily scratched hand-slip glass, low processing efficiency, and a lot of time, to improve the fixing time, Easy to operate and easy to disassemble

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

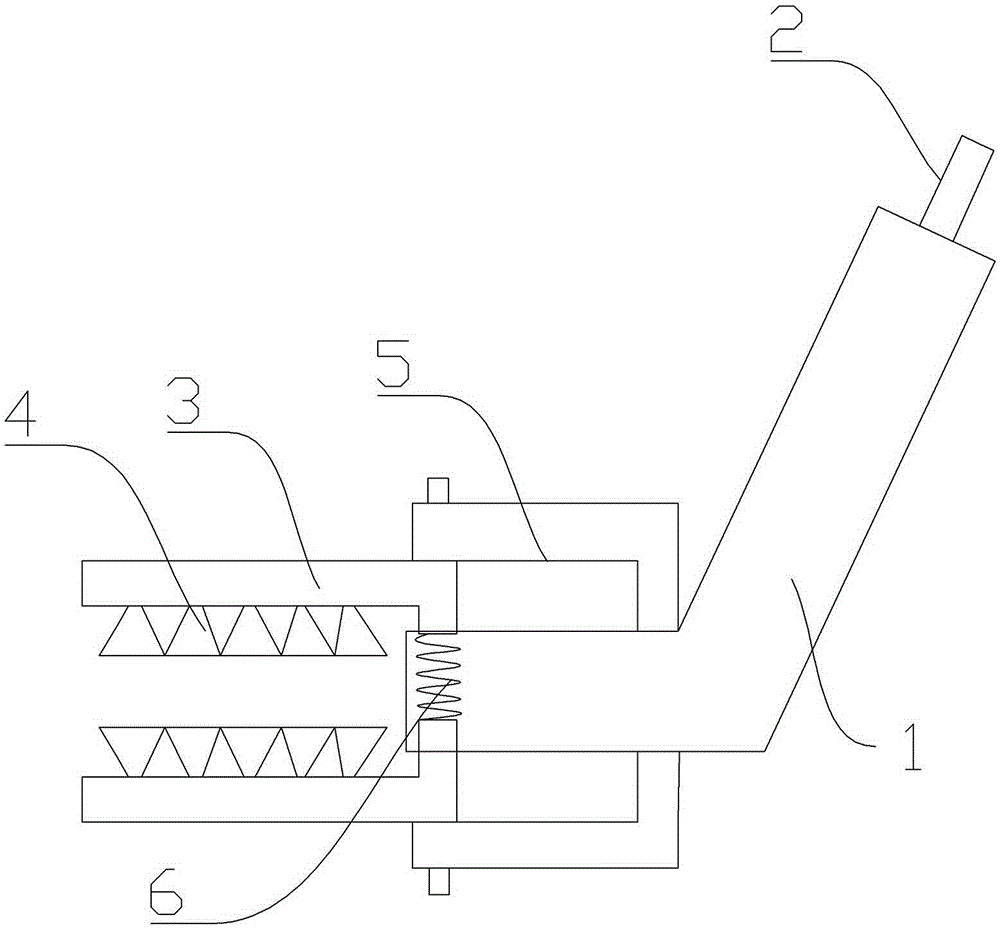

Embodiment 2

[0017] Embodiment 2 is basically as figure 2 As shown, it is improved on the basis of Embodiment 1, and the end of the suction cup 4 is set as a plurality of suction nozzles, and each suction nozzle is evenly and closely arranged. Using multiple suction nozzles to absorb the glass, compared with using one suction cup 4 and one suction nozzle, under the same contact area, the adsorption force of multiple suction nozzles is stronger, because if there is a gap or groove in the glass, one suction cup 4 one The adsorption force of the suction nozzle will be greatly reduced, and when multiple suction nozzles are used, when a small gap appears, it will only affect one suction nozzle and have almost no effect on the adsorption force of other suction nozzles.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com