Sealed sampling device for gas sample

A technology for sampling device and gas sample, which is applied in the direction of extraction of undisturbed cores, earthwork drilling, etc., can solve the problems of affecting the entry of cores into the inner cylinder and cannot achieve airtight coring, etc., and achieves a wide range of applications, compact device structure, and sealing effect. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

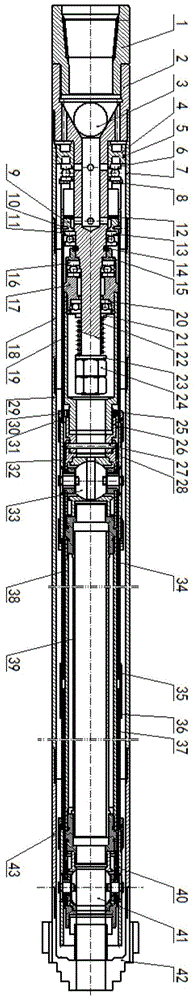

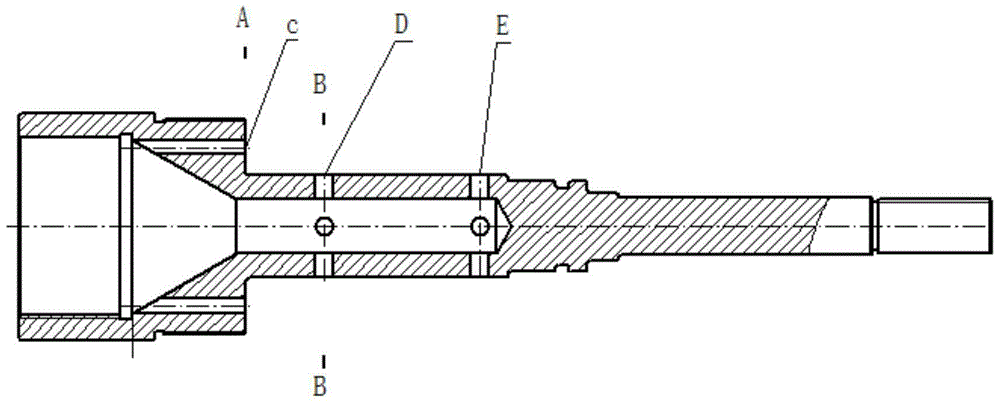

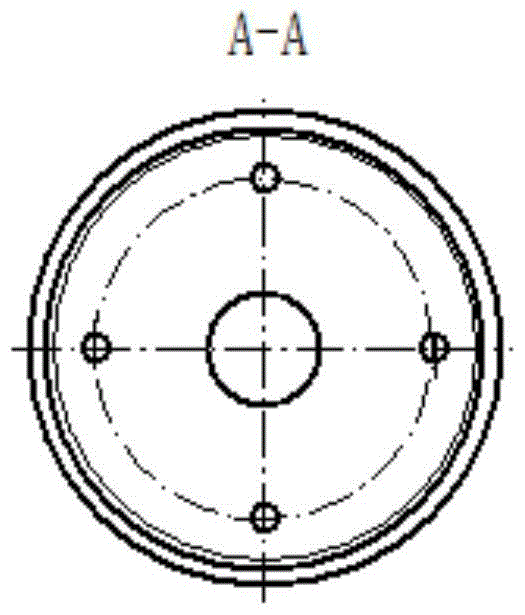

[0036] see figure 1 , shows the gas sample airtight sampling device of the present invention.

[0037] The airtight sampling device for gas samples is arranged in three layers, respectively forming different functions and effects, and is divided into an outer pipe, an inner pipe and a two-layer pipe. The outer pipe includes a connecting mandrel 2, a drill bit 42 and A connecting pipe assembly located between the connecting mandrel 2 and the drill bit 42, the rear end of the connecting mandrel 2 is also provided with a protective joint 1 connected to the driving source, so that the drilling of the drill bit 42 can be realized through the rotation of the driving source and exit.

[0038] Wherein, the connecting pipe assembly comprises a cylinder barrel 7, a first outer tube 18, a second outer tube 29 and a third outer tube 43 which are threaded in sequence, the cylinder barrel 7 is threadedly connected to the connecting mandrel 2, and the first The three outer pipes 43 are thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com