Titanium alloy smithing technological parameter testing method

A test method and technology of process parameters, applied in the field of metal material science, can solve the problems of few places to cut mechanical performance samples, complex forging shapes, and inability to quantitatively study deformation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

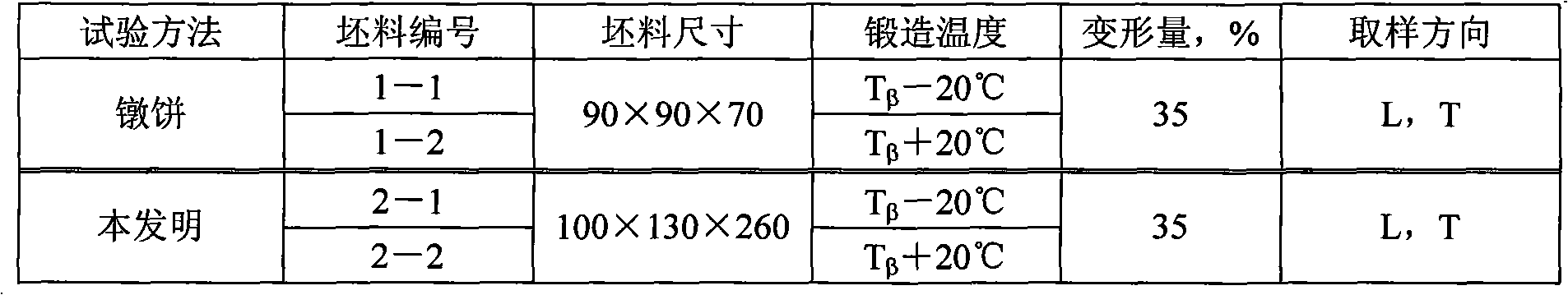

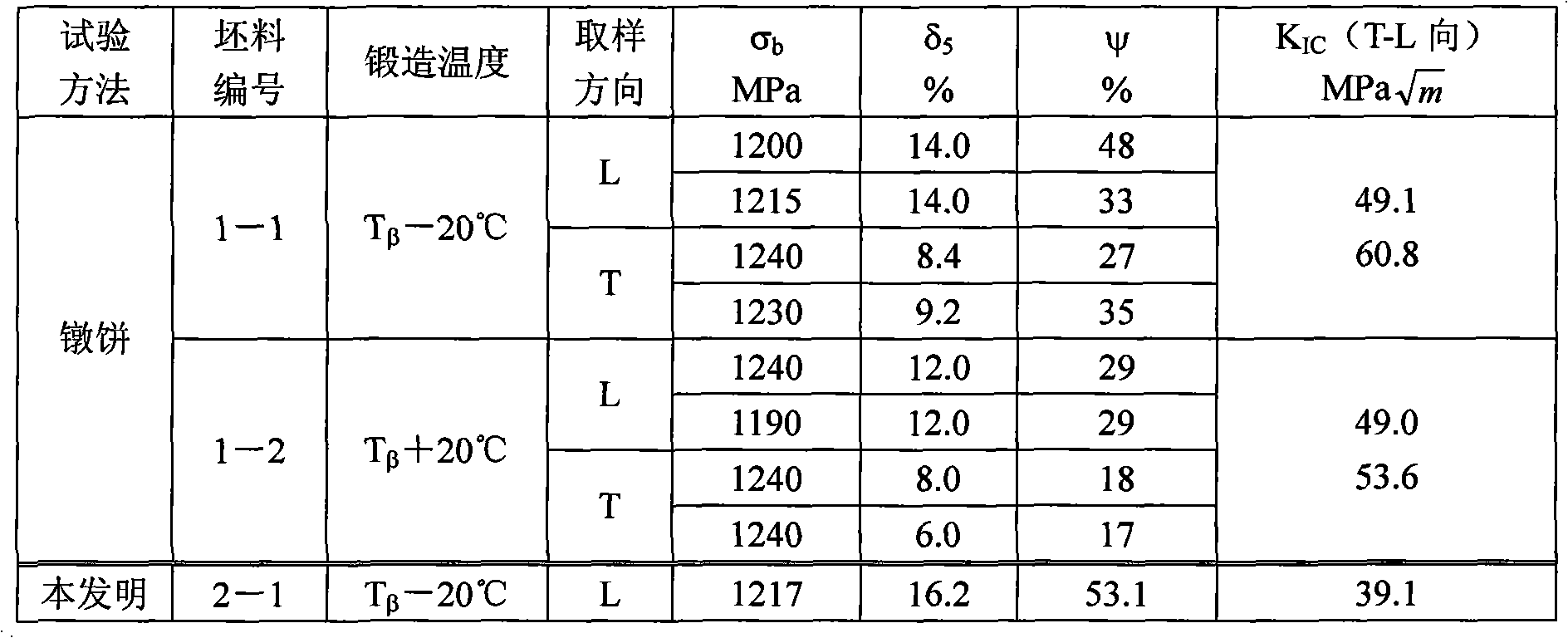

[0021] The comparative test of embodiment 1 upset cake method and the inventive method

[0022] The raw material is TC18 (Ti-5Al-5Mo-5V-1Cr-1Fe) titanium alloy φ155mm rod. First to the bar at T β Forgings in all directions at -30°C are completed in two fires, and each fire is upsetting once, and the upsetting deformation is about 50%. Forge the bar after forging to the size given in Table 1, then respectively adopt the upsetting cake method and the test method of the present invention to forge the blank. The specific process parameters of the inventive method are shown in Table 1 and the following steps:

[0023] 1) Forging titanium alloy rods in multiple fires in all directions to obtain as uniform an original structure as possible, and the low-magnification structure should conform to grades 1 to 3 in the "Titanium Alloy Low-magnification Structure 10-Grade Rating Chart";

[0024] 2) The reforged bar is made into a blank with a thickness of 100±2mm, a width of 130±2mm, and...

Embodiment 2

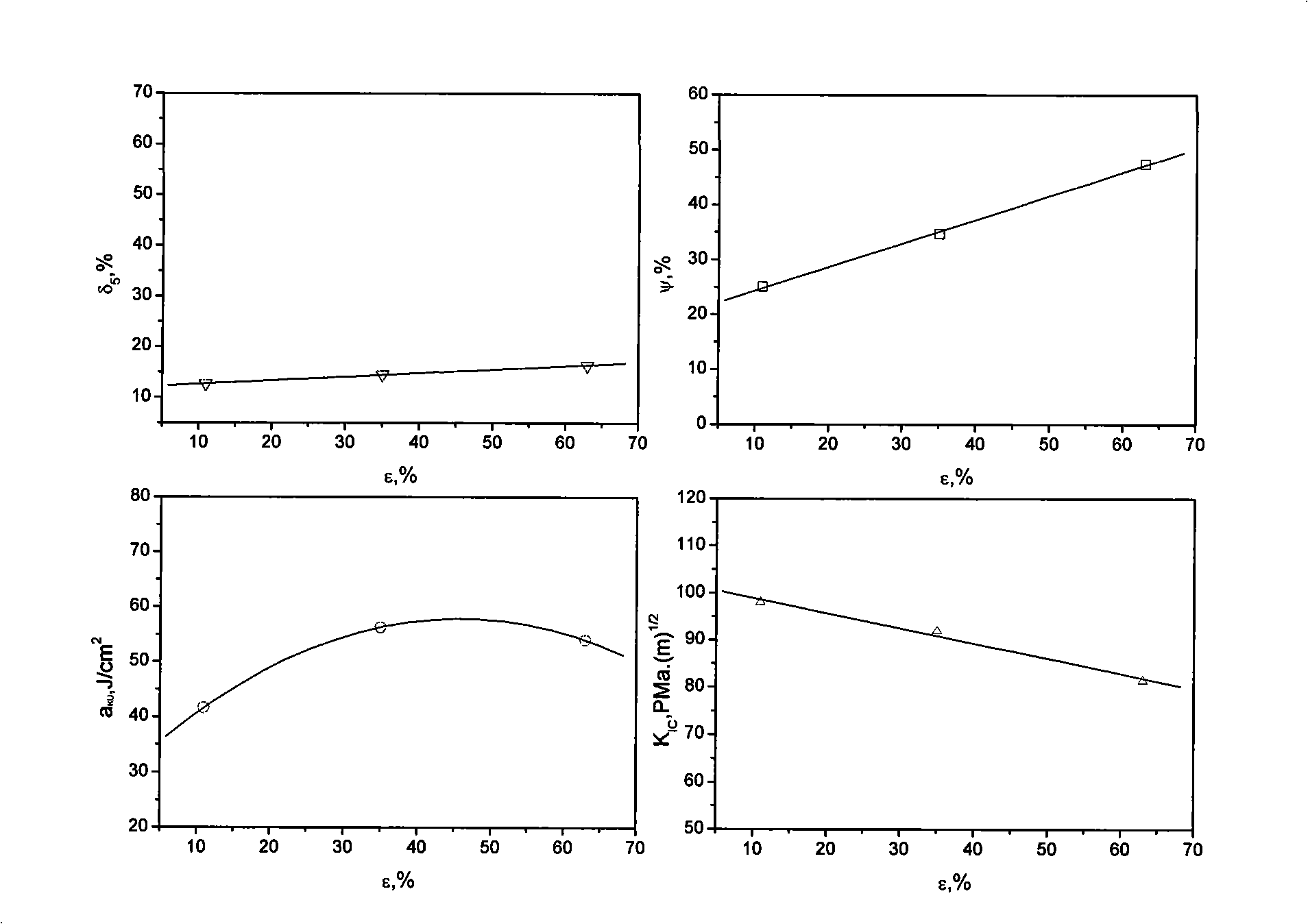

[0037] The raw material is TC18 titanium alloy φ170mm bar. First, the bar is forged in all directions at Tβ-40°C, and it is completed in three fires. Each fire is upset once, and the upsetting deformation is about 50%. The size of the blank after forging is 100×130×260mm. The die forging heating temperature is Tβ+25℃, and the holding time is calculated in two stages: T β -30°C, hold for 60 minutes, heat up to Tβ+25°C with the furnace, hold for 40 minutes. The test results of mechanical properties are shown in Table 3, and the corresponding relationship between deformation and mechanical properties is shown in figure 1 .

[0038] Table 3 Test results of main mechanical properties of TC18 titanium alloy forgings under different deformation

[0039]

[0040] Note: The post-forging heat treatment system is 825°C, 2h, furnace cooling to 750°C, 2h, AC+620°C, 4h, AC.

[0041] Depend onfigure 1 It can be seen that at the selected test temperature, the amount of deformation has ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com